TSX1D200MTS V1 FEB13

- 5 -

ENVIRONMENT

•

The welding environment should be dry, where humidity is below 90%

•

The environment temperature should range between 10˚C and 40˚C

•

Protect the machine against heavy rain, or in hot environments out of direct sunlight

•

Do not allow the machine to come into contact with water

•

Keep the environment free of dust, acid and corrosive gases

•

Ensure the environment is free from drafts

The SifWeld MTS200 welding machine has been installed with a pressure, flow and overheating protection

circuit. When the network voltage, output current and machine temperature exceeds a set standard, the

machine shall automatically stop working.

However, excessive use (such as high voltage) can still lead to damage of the welding machine, therefore

you shall need to pay attention to the following:

Ensure Good Ventilation

The SifWeldMTS 200 is a small sized welding machine which has an internal cooling fan to regulate

operating temperature during use. For optimum ventilation, the operator must ensure there is sufficient space

between the machine and surrounding objects, this must be a minimum of 30cm. It is vital to keep the

machine serviced and maintained on a regular basis.

Duty Cycle

The operator should always consider duty cycles for the current they are welding at, ensuring the duty cycle

is not exceeded. Should the duty cycle be exceeded, the Thermal Cut Out will engage therefore halting

welding operation. At the same time the overheating signal on the front panel shall activate and light up. In

this instance

do not

unplug the machine, however allow the fan to cool the machine to the required

temperature to start welding again.

Current overload will reduce the service life, and could result in damage of the machine and even burning out

of the thermal inverter.

Mains Input Supply

Refer to the Recommended Weld Parameters within this manual for your chosen application.

Use the correct voltage input for your application, and ensure this is not exceeded. Voltage above the

maximum permitted voltage may cause damage to the welding machine.

Make sure the earth cable is connected correctly prior to using the machine to remove necessary

residual voltage.

2

Introduction

The SifWeld MTS200 is an inverter welder which adopts the latest Insulated Gate Bipolar Transistor (IGBT)

technology. The working principle is to use a single tube IGBT switching device rectifying input power into a

DC output then inverted to a high frequency, then stepped-down through the pulse width modulator (PWM)

to produce the welding output.

Using a digital liquid crystal (LCD) display panel, weld parameters can be adjusted via the MCP (Mono

Control Point) easily and accurately. The feedback circuit gives precise control of the welding arc, therefore

providing excellent welding characteristics.

The SifWeld MTS200 is an easily portable, multi-functional machine suitable for both on-site and workshop

use. Boasting stable wire feed speed, no electromagnetic noise, good arc force, molten pool and low spatter

along with high duty cycle. This unit is also energy efficient and is suitable for the welding of various

materials.

Summary of Contents for MTS 200

Page 1: ...MTS 200 User Manual SWMTS001 TSX1D200MTS ...

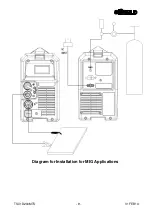

Page 9: ...TSX1D200MTS V1 FEB13 9 Diagram for Installation for MIG Applications ...

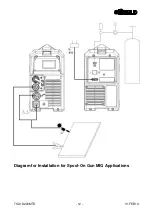

Page 12: ...TSX1D200MTS V1 FEB13 12 Diagram for Installation for Spool On Gun MIG Applications ...

Page 14: ...TSX1D200MTS V1 FEB13 14 Diagram for Installation for TIG Applications ...

Page 16: ...TSX1D200MTS V1 FEB13 16 Diagram for Installation for MMA Applications ...

Page 22: ...TSX1D200MTS V1 FEB13 22 4 Hot Start ...

Page 27: ...TSX1D200MTS V1 FEB13 27 8 Parts List Circuit Diagram Parts Diagram ...