Page

23

Document Number: 0072

Rev. 09

CONTROLLED COPY

10. INSTALLATION

10.1 CONNECTOR & PENETRATOR INSTALLATION

It is recommended that the installation of all SpecTRON Penetrators and Mounted Connectors is

undertaken by Siemens Subsea site engineers or trained personnel.

10.2 HOSE COMPENSATION

The hose within a pressure balanced oil filled (PBOF) jumper performs two functions:

mechanical protection to the cables inside and forming a primary barrier between the

electrical insulation and seawater. The cable is not fixed and can move within the hose volume,

testing by Siemens Energy has shown that the three conductors lay next to each other at the bottom

of the hose in direct contact with the hose inside diameter.

The oil volume within a hose is compensated through changes in the cross-sectional profile of the

hose.

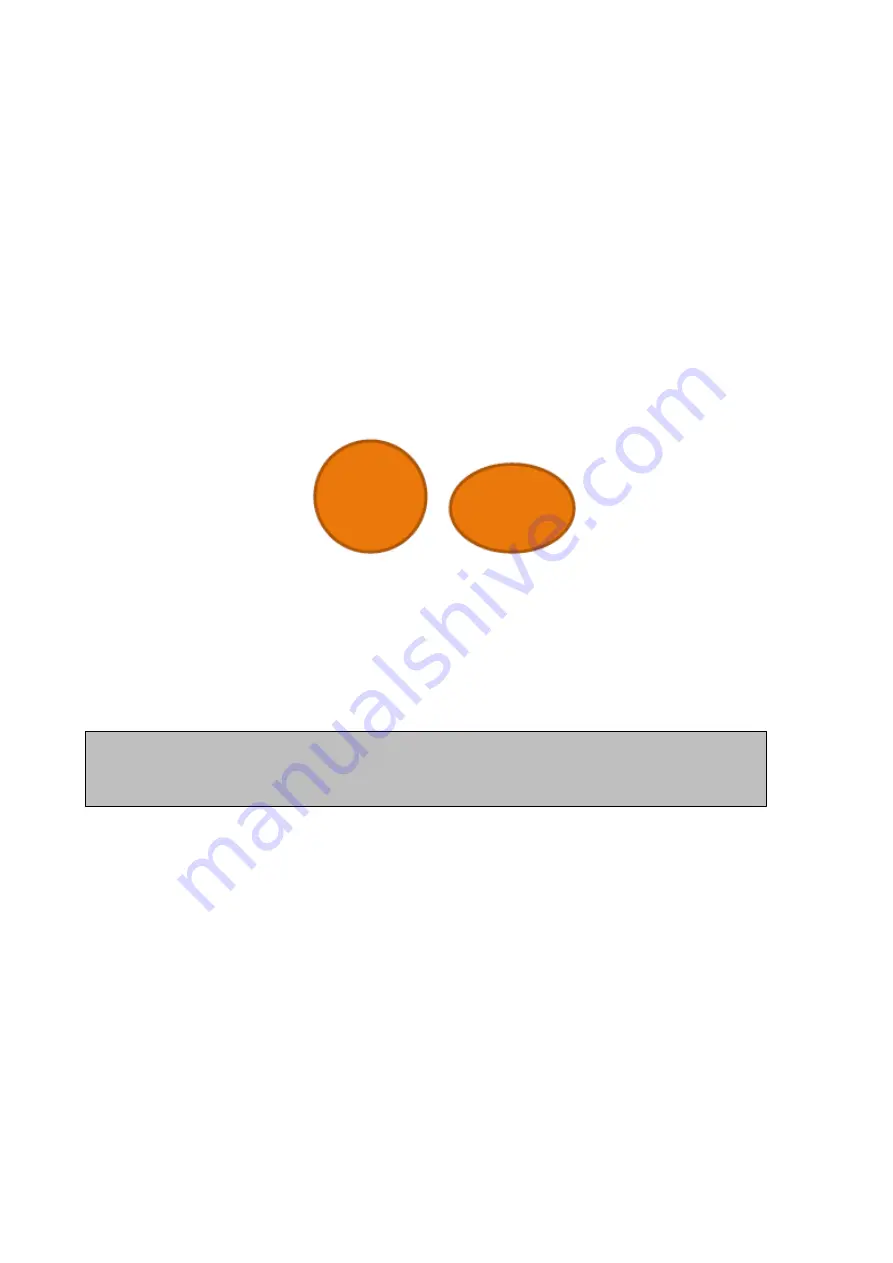

Figure 17

- Hose Profile, (left to right), as filled, and when compensating

AquaTRON 200 harnesses (Orange Hose) are provided from factory with a 10bar internal

overpressure, however due to the flexible nature of the materials involved it is possible that some

over pressure may be lost during shipping and storage. This is dependant on a no. of factors

including length and temperature. However a positive pressure will always be maintained and no

flattening of hose should be observable topside.

Once deployed a certain amount of flattening is expected (dependant on deployment depth), this is

an ordinary occurrence related to the compensation system of the harness. Harness is designed to

equalise the pressure between the external seawater depth pressure and the internal oil filled hose.

The amount of compression is directly related to depth pressure, but all depth extremes have been

considered. As long as harness is routed to MBR there shall be no adverse effects to electrical

conductors within hose (see section 10.3 for guidance on routing).

Should any kinking (abrupt change in direction below MBR) of the hose be observed, the harness

should be re-routed/deployed to try and remove the feature. If this continues it could indicate a lack

of internal pressure. In which case the harness should be recovered for further inspection topside,

including:

•

Thorough visual inspection of the retrieved jumper for damage and correct

shape, indicating the hose pre-charge pressure remains acceptable.

•

Insulation resistance measurement to validate the electrical performance of the jumper.

Note:

1.5” Gorilla Harnesses (Yellow Hose) are not provided with an internal over

pressure, this is not required at their rated depth of deployment. However the guidance

below should still be followed.

Summary of Contents for SpecTRON 5

Page 1: ......