Technical data

B

Configurator for drive technology

You can find product information on your motor according to ErP Directive 2019/1781 in the

configurator for drive technology. If you enter the motor order number (MLFB), you will find

technical documentation such as data sheets, characteristic curves and CAD drawings for your

motor: www.siemens.com/dt-configurator

B.1

Tightening torques

B.1.1

Tightening torques for screw and bolt connections

Bolt locking devices

• Refit nuts or bolts that are mounted together with locking, resilient, and/or force-distributing

elements with identical, fully-functional elements when re-assembling. Always renew keyed

elements.

• When screwing together threads secured with a liquid adhesive, use a suitable medium such

as Loctite 243.

• Always use suitable securing devices or removable adhesives (e.g., Loctite 243) when

installing fixing bolts with a clamping length of less than 25 mm. The clamping length is

taken as the distance between the head of the bolt and the point at which the bolt is screwed

in.

Tightening torques

The bolted connections with metal contact surfaces, such as end shields, bearing cartridge

parts, terminal box parts bolted onto the stator frame, should be tightened to the following

torques, depending on the thread size:

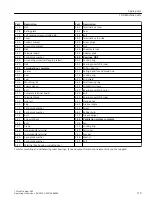

Table B-1

Tightening torques for bolted connections with a tolerance of ±10 %.

Thread

∅

M5

M6

M8

M10

M12

M16

M20

M24

Nm

5

8

20

40

70

170

340

600

The tightening torques stated above apply to screws with property class 8.8, A4-70 or A4-80

according to ISO 898-1, however only to bolts screwed into components made from materials

with the same or higher property class, e.g. cast iron, steel or cast steel.

1FZ shaft height 280

Operating Instructions, 02/2022, A5E51698698A

131

Summary of Contents for SIMOTICS DP

Page 2: ......

Page 140: ...Index 1FZ shaft height 280 138 Operating Instructions 02 2022 A5E51698698A ...

Page 141: ......