RUGGEDCOM MX5000RE

Installation Guide

Chapter 1

Introduction

Decommissioning and Disposal

7

B

D

E

A

C

G

F

H

I

J

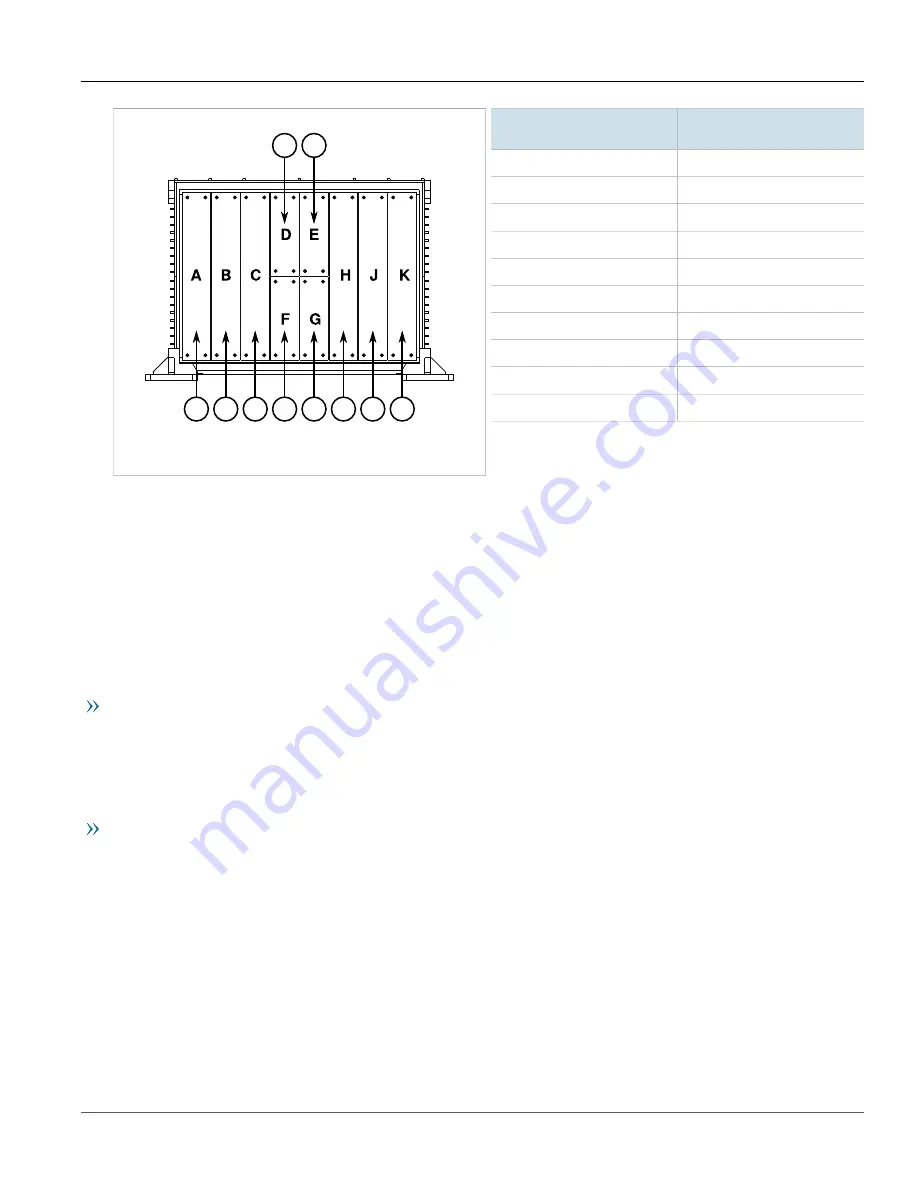

Figure 4: Patch Panels

Patch Panel

RUGGEDCOM

MX5000RE Module Slot

A

LM1

B

LM2

C

LM3

D

CM

E

PM1

F

SM

G

PM2

H

LM4

I

LM5

J

LM6

For information about how to install patch panels, refer to

Section 2.11, “Installing the Patch Panels”

.

Section 1.6

Decommissioning and Disposal

Proper decomissioning and disposal of this device is important to prevent malicious users from obtaining

proprietary information and to protect the environment.

Decommissioning

This device may include sensitive, proprietary data. Before taking the device out of service, either permanently or

for maintenance by a third-party, make sure it has been fully decommissioned.

For more information, refer to the associated

User Guide

.

Recycling and Disposal

For environmentally friendly recycling and disposal of this device and related accessories, contact a facility

certified to dispose of waste electrical and electronic equipment. Recycling and disposal must be done in

accordance with local regulations.