Technical information

7.5 Technical specifications

Industrial Flat Panel IFP1500, IFP1900, IFP2200, IFP1900 PRO, IFP2200 PRO, IFP1900 ETH, IFP2200 ETH

Operating Instructions, 07/2016, A5E31298376-AF

103

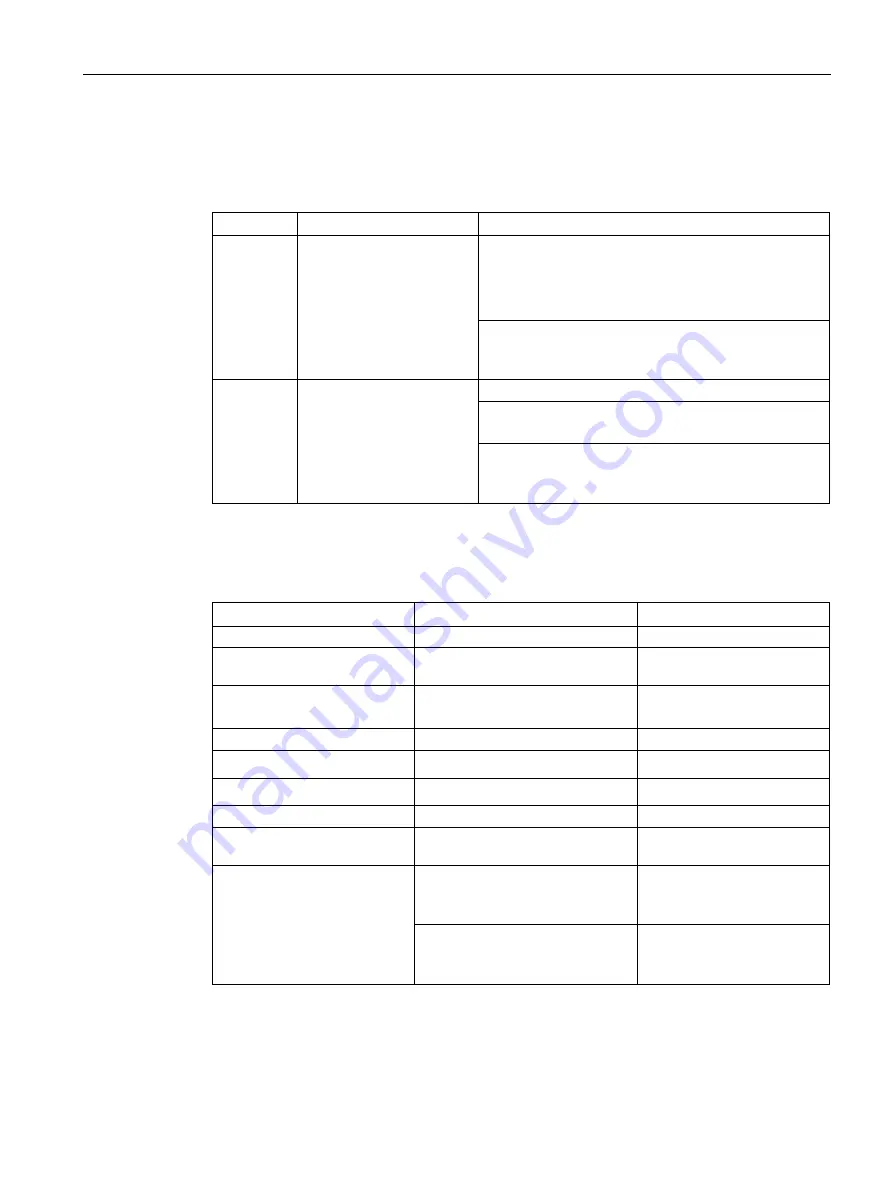

Testing mechanical ambient conditions

The table below provides information on the type and scope of tests for mechanical ambient

conditions.

Tested for

Test standard

Comments

Vibrations

Vibration test in accordance

with IEC 60068, part 2-6

(sinusoidal)

Type of vibration:

Frequency cycles at a rate of change of 1 octave/minute.

5 Hz ≤ f ≤ 8.4 Hz, constant amplitude 3.5

mm

8.4 Hz

≤ f ≤ 200 Hz, constant acceleration

1 g

Vibration duration:

10 frequency cycles per axis in each of the three

mutually vertical axes

Shock

Shock test in accordance

with IEC 60068, Part 2-27

Type of shock: Half-sine

Severity of shock:

Peak value 15 g, duration 11 ms

Direction of shock:

3 shocks in ± direction of axis in each of the three axes

vertical to each other

Climatic ambient conditions

The following table shows the climatic ambient conditions for operation of the device.

Ambient conditions

Permitted range

Comments

Temperature built-in units:

•

Vertical mounting

0 ... 50 °C (landscape format)

1

0 ... 40 °C (portrait format)

•

Mounting at an angle

0 ... 40 °C (landscape format)

0 ... 35 °C (portrait format)

Slope angle max. 35°

Temperature PRO devices:

•

Vertical mounting

0 ... 45 °C (landscape format)

•

Inclined mounting

0 ... 45 °C (landscape format)

Tilt angle max. 45°

Relative humidity

10 ... 90%, without condensation

Atmospheric pressure

1 080 to 795 hPa

Corresponds to an elevation

of -1000 m to 2000 m

Pollutant concentration

SO

2

: < 0.5 vpm;

Relative humidity <60%,

no condensation

Test: 10 cm

3

/m

3

; 10 days

H

2

S: < 0.1 vpm;

Relative humidity <60%,

no condensation

Test: 1 cm

3

/m

3

; 10 days

1

IFP1900 and IFP2200: From 0 to 45° C