HART add-on module

11

Bit

Definition

7

Device Malfunction

– The device detected a serious error or failure that compromises device

operations. This flag is set whenever an error of category „Fatal Error“ is pending in the

flowmeter. Detailed information can be found via HART command 48.

6

Configuration Changed

– An operation was performed that changed the device’s configuration.

Any HART command, which writes information to the flowmeter, will set this flag. The flag can

be reset using command 38. The flag is handled separately for each HART master (primary/

secondary). Note: In the flowmeter, the flag is NOT stored during power cycles.

5

Cold Start

– A power failure or Device Reset has occurred. This flag is only set in the first

response transmitted to a Hart Master after power failure. The flag is handled separately

for each HART master (primary/secondary).

4

More Status Available

– More status information is available via Command 48, Read Additional

Status Information. This flag is set, whenever a transmitter specific error or

warning is active

in the flowmeter.

3

Loop Current Fixed

– The Loop Current is being held at a fixed value and is not responding to

process variations. This flag is always set, if the transmitter is in Multidrop mode – i.e. the

Hart address is not zero. This flag is also set in SingleDrop mode, if the flowmeters current

output is forced in Service Mode or via Hart Command #40.

2

Loop Current Saturated

– The Loop Current has reached its upper (or lower) endpoint limit

and cannot increase (or decrease) any further. This flag is set whenever the flowmeters

overflow warning (error no. 30) is pending.

1

Non-Primary Variable Out of Limits

– A Device Variable not mapped to the PV is beyond its

operating limits. This flag is always zero in the flowmeter (ie not used).

0

Primary Variable Out of Limits

– The PV is beyound its operating limits. This flag is set

whenever the flowmeters overflow warning (error no. 30) is pending.

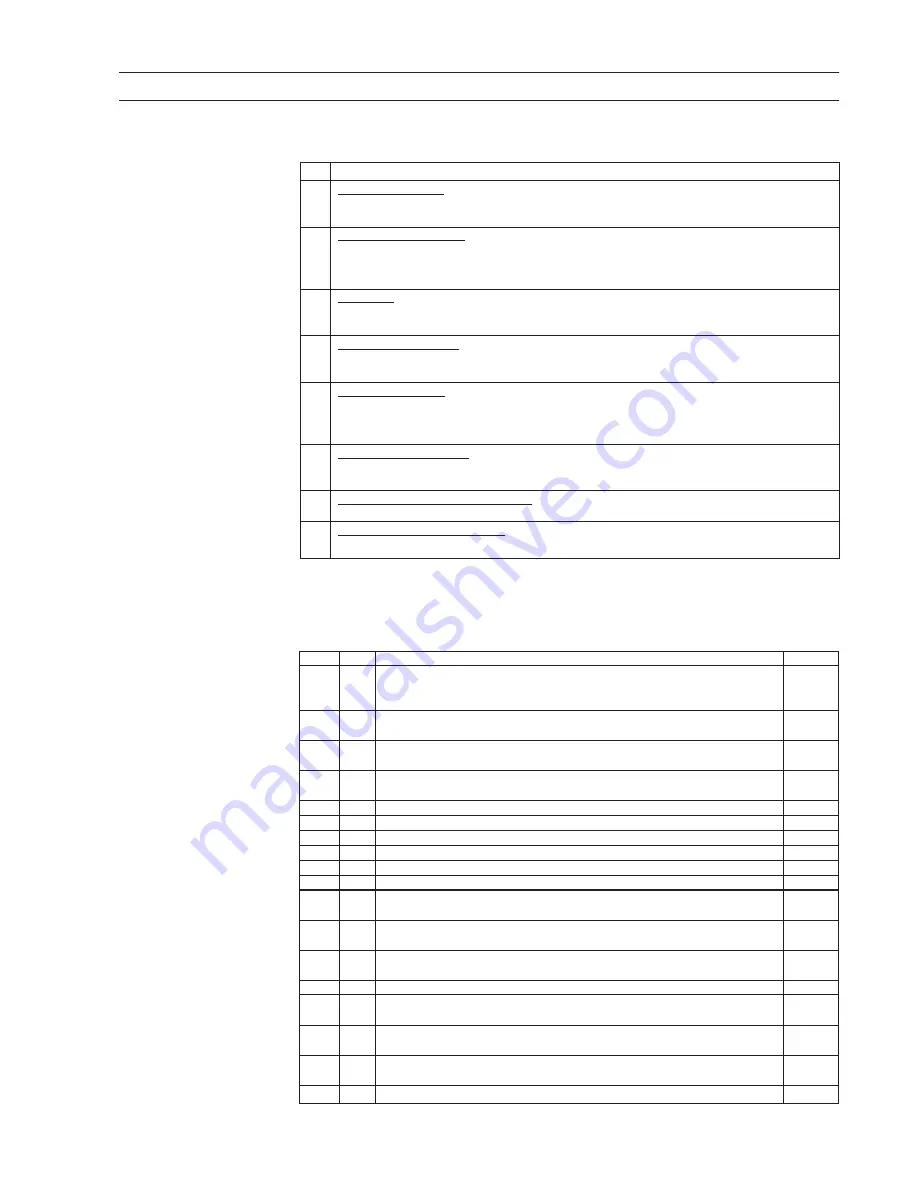

This chapter defines all status provided by the flowmeter including: the Device status byte; the

Extended Device Status byte; and status information returned in Command 48.

7. Status Information

7.1

Device status

7.2

Extended device

status

The extended device status bits are not supported by the flowmeter. Value is always zero.

7.3

Additional device

status (Command

48)

Command 48 returns 25 bytes of data. Bits not listed in the table below are set to zero. For detailed

USM II error number descriptions please look in the MAG/MASS manual, Literature 1 and 2.

Byte

Bit

Meaning

Class

0

0

Set if any

Warnings

are active

– See bytes18-21 below

1

Set if any

Permanent errors

are active – See bytes 14-17 below

mode

2

Set if any

Fatal errors

are active – See bytes 1-5 below

1

0-7

USM Fatal Error 60, 61, 62, 63, 70, 71, 80, 81

(bit 0 corresponds to error 60, bit 7 to error 81)

error

2

0-7

USM Fatal Error 82, 83, 84, 96, 97, 64, 65, 66

(bit 0 corresponds to error 82, bit 7 to error 66)

error

3

0-7

USM Fatal Error 67, 68, 69, 72, 73, 74, 75, 76

(bit 0 corresponds to error 67, bit 7 to error 76)

error

4

0-2

USM Fatal Error 77, 78, 79

(bit 0 corresponds to error 77, bit 2 to error 79)

error

5

0-7

Reserved (=0)

6

0-7

Extended Device Status Not supported (=0)

mode

7

0-7

Device Operating Mode Not supported (=0

)

mode

8-10

0-7

Analog Channel Saturated Not supported (=0)

mode

11-13

0-7

Analog Channel Fixed Not supported (=0)

mode

14

0-7

USM Permanent Error 40, 41, 42, 43, 44, 45, 46, 47

(bit 0 corresponds to error 40, bit 7 to error 47)

error

15

0-7

USM Permanent Error 48, 49, 94, 95, 50, 51, 52, 53

(bit 0 corresponds to error 48, bit 7 to error 53)

error

16

0-5

USM Permanent Error 54, 55, 56, 57, 58, 59

(bit 0 corresponds to error 54, bit 5 to error 59)

error

17

0-7

Reserved (=0)

18

0-7

USM Warning 20, 21, 22, 23, 24, 30, 31, 90

(bit 0 corresponds to error 20, bit 7 to error 90)

warning

19

0-7

USM Warning 91, 92, 93, 25, 26, 27, 28,2 9

(bit 0 corresponds to error 91, bit 7 to error 29)

warning

20

0-7

USM Warning 32, 33, 34, 35, 36, 37, 38, 39

(bit 0 corresponds to error 32, bit 7 to error 39)

warning

21-24

0-7

Reserved (=0)

7.

Status Information