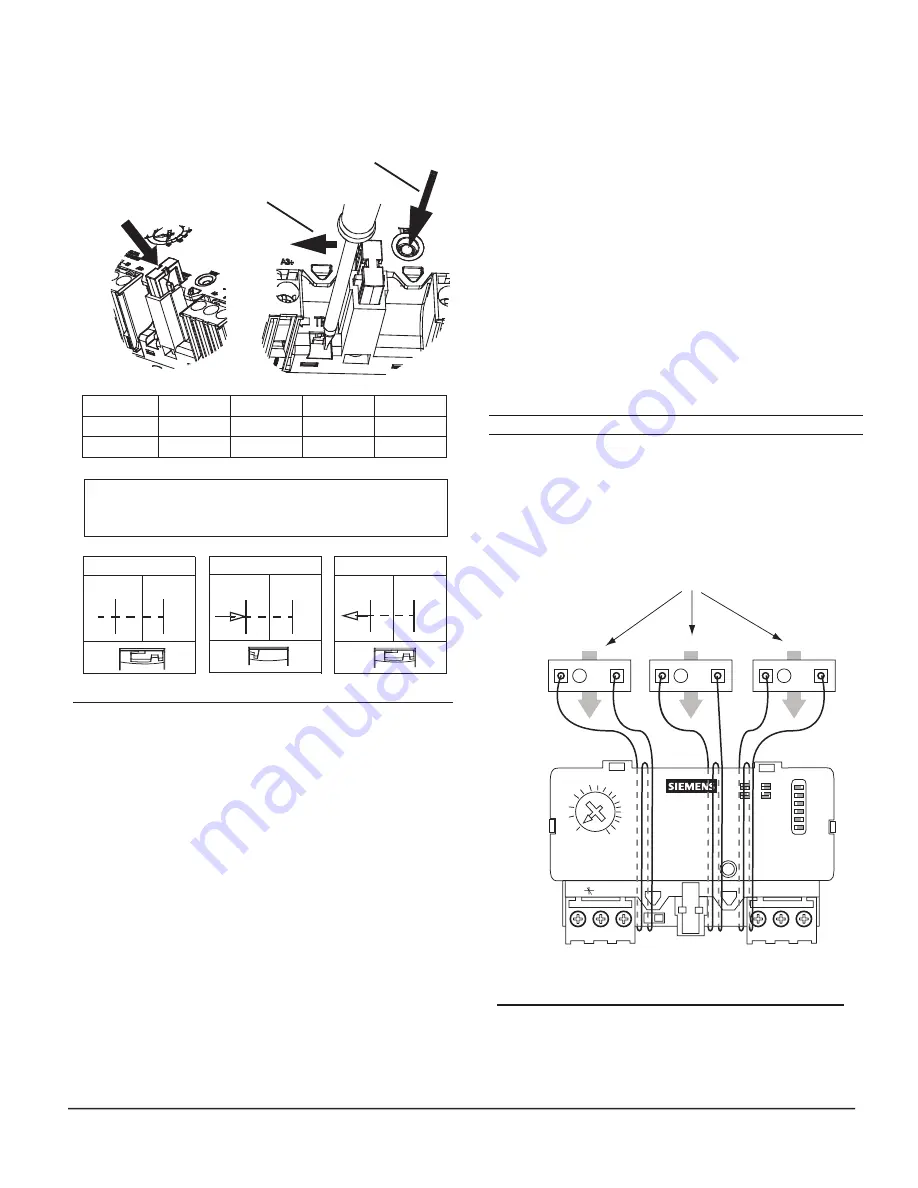

7 Looping Option

The following table demonstrates how the looping process reduces

the current setting of the overload by the number of times the wires

pass through the windows of the overload.

All current values are expressed in amperes.

Overload

Number

Number of Times

Current

of

Wire Passes

Range

Loops

Thru Window

Shown on label

10 - 40

0

1

Option A

5.0 - 20

1

2

Option B

3.0 - 12

2

3

Option C

2.5 - 10

3

4

Option D

2.0 - 8

4

5

Option E

1.5 - 6

5

6

Current CT

Range

Ratio

Cat #

3UB81234JW2

100-300 300.5

2

3UB81234KW2

133-400 400.5

2

3UB81234LW2

200-600 600.5

2

3UB81234MW2

250-750 750.5

2

3UB81234NW2

400-1220

1200.5

2

# of times

wire passes

through window

for ESP200 with windows

In applications involving the use of 12 or 14 AWG wire, usually motors of

5HP or less, the wires maybe looped and passed through the windows

repeatedly before connecting to the contactor. By looping the motor

leads through the windows in the overload a second time, the overload

will read twice the current actually going to the motor. Hence the

overload can protect a motor needing half the FLA capability of the

overload. An overload with a current of 10 to 40 amperes can be used for

a motor FLA between 5 to 20 amperes.

Similarly, motors that require only one-third, one-fourth, or one-fifth the

overload’s FLA capability can use the same size ESP200 starter by

looping three, four, or five times.

Hot Terminals

Possible cause: Loose wire connections

Action:

Clean connections and tighten to recommended torque.

Failure To Trip Out

Possible cause: Incorrect dial setting

Action:

Readjust dial setting to the FLA on the motor nameplate.

Overload Trips

Possible cause: Motor is overloaded

Action:

Remove cause of overload and reset overload relay.

Possible cause: Loss of phase

Action:

Replace burnt-out fuse, or reconnect wire in missing phase.

Possible cause: Dial setting is too low

Action:

Readjust dial setting to the FLA on the motor nameplate.

Possible cause: Unbalance Phase

Action:

Correct the power system.

Possible cause: Ground Fault

Action:

Fix the fault and restart.

Possible cause: Set at the wrong trip class

Action:

Reset the dip switches to the correct trip class.

6 Troubleshooting

3

Siemens Industry, Inc. 5300 Triangle Parkway, Norcross, GA 30092 www.usa.siemens.com

5 Reset and Test Buttons

READY

RESET

Trip Class

5

10

20

30

*

3 min.

5 min.

10 min.

15 min.

**

0.5 min.

1 min.

2 min.

3 min.

Contact Test

Device Test

(electronic functions)

NC 95 96

NO 97 98

O

O

O

O

TEST

NC 95 96

NO 97 98

RESET

NC 95 96

NO 97 98

O

O

O

O

O

O

O

O

Fig. 8

8 ESP200 wiring with External CTs

Fig. 9

ESP200

FULL LOAD AMPS

RESET

TEST

CAT.NO.

48ATC3S00

3UBB123-4CW2

95

96

A3+

A4- 97 98

5

6

4

3

12

10

7

8

9

5

TRIP CLASS

PHASE UNBAL ON

PHASE LOSS ON

OFF

OFF

RESET MODE MAN

GROUND FAULT ON

AUTO

OFF

10

20

30

X1

L1

X1

L2

X1

L3

Current Transformers (CT)

Note:

Must have at least 80% of Motor amps for this test to work.

* The device must be energized with a running motor for at least the

minimum time, shown in the table.

** Then the test button can be pushed and held until the device trips.

The trip time depends on the selected Trip Class as shown in the table.