Document No: IOM-002

Issue Date:

24/09/2020

Revision:

6

Page:

32 of 42

Unrestricted

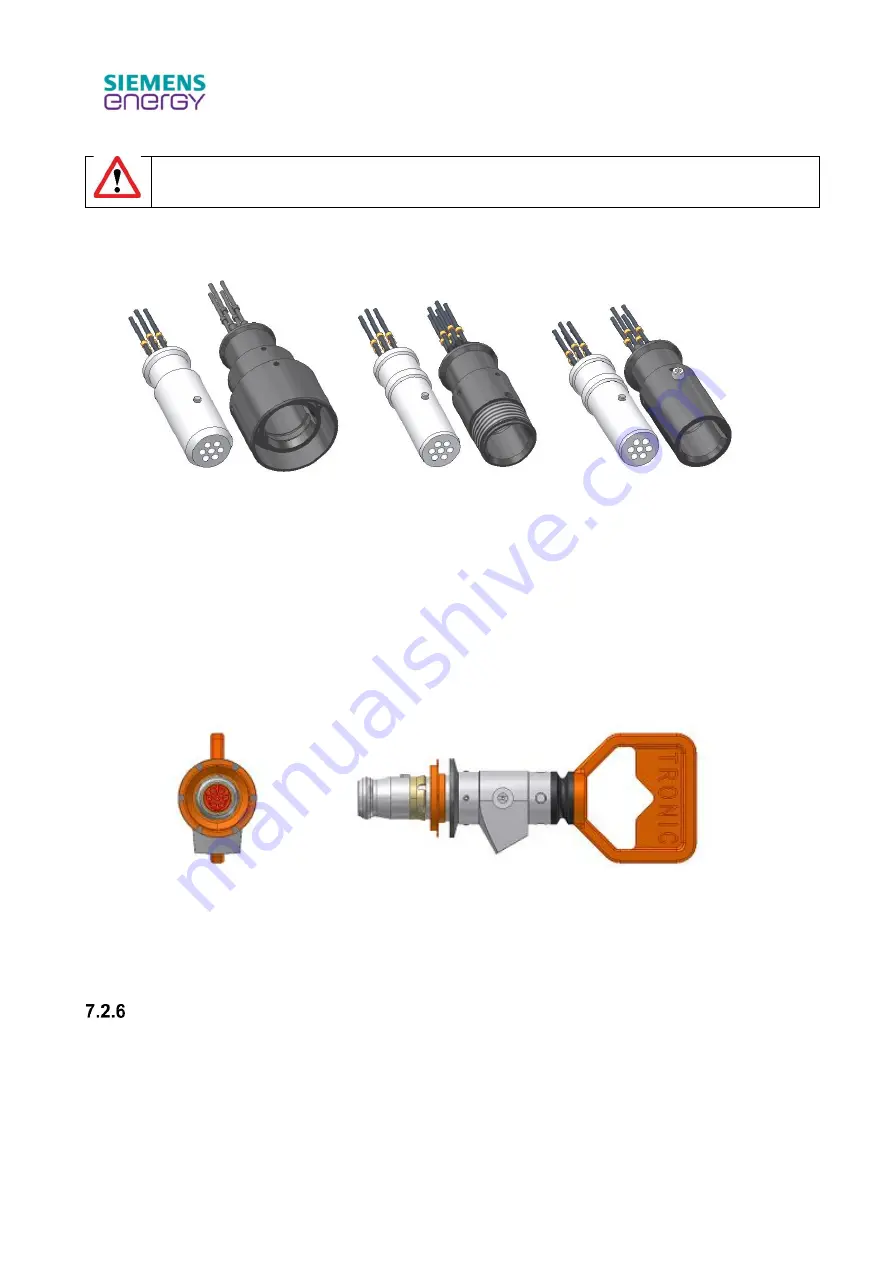

Caution

. Risk of material damage. Test connectors should never be used in water. There

is a high change of damage to the test connector and also to the connector under test.

Below are some images of standard dry (topside) Siemens Energy test connectors.

Figure 19

Dry (Topside) Test connectors, ROV, Diver and Stab-plate type

Alternatively, a standard subsea connector (e.g. Figure 20) tailed with cable can be used as a test

connector. This is preferred by some users as it hides the rubber termination sleeves inside the

body of the connector, eliminating the possibility for the rubber termination sleeves to be removed

by the user (refer to Danger! notes above).

Siemens can provide such connectors tailed with appropriate cables (Siemens recommendation),

or untailed.

See section 7.2.6 for instruction on installing cable tails.

Figure 20

Example of standard subsea connector (shown untailed)

Installation of cable tails (applies to all products)

Siemens connectors can be supplied with tails (Siemens recommendation) or without.

Cable tails require soldering into the solder cups on the rear of the connector. Each termination

must be protected by a termination sleeve supplied with the connector.

Only a Suitably Qualified and Experienced Person (SQEP) should install the cable tails, e.g.

person trained by Siemens Energy.

Siemens Energy installation procedure should be used.