3.4

Removing / Fitting ROD 320, ROD 426,

absolute value encoder

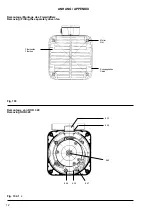

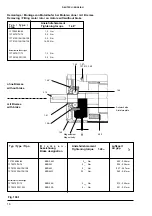

3.4.1 ROD 320 (8.21)

Removing (see Fig. 104.1)

- Remove screws (8.45)

- Release socket (8.33)

- Unscrew cover screws (8.43)

- Remove cover (8.06/1F506.-8.59)

- Remove screw (8.49), holding encoder (8.21) with 19 mm spanner;

prevent motor rotor from turning at the same time if necessary

- Remove screws (8.47 and 8.48) from the spring clip (8.29)

NOTE: Do not allow encoder to hang to the side on spring clip without

screws removed

- Screw in grub screw (e.g. DIN 913 M8 x 16) through encoder hub in the

double-taper sleeve (8.22) to a depth of approx. 7 mm

- Screw in screw (e.g. DIN 933 M8 x 70-8.8) into encoder, holding motor

rotor with 19 mm spanner, until encoder comes free - max. torque 20 Nm

NOTE: Do not damage locating pin (8.16)

- Remove DIN933 M8 x 70-8.8 screw from encoder

- Screw in DIN913 M8 x 16 grub screw in the double-taper sleeve on the

speed sensor rotor to a depth of approx. 6 mm

- Screw in DIN933 M8 x 70-8.8 screw in the double-taper sleeve and

remove, holding speed sensor rotor with 19 mm spanner - max. torque

20 Nm

Fitting (see Fig. 104.2)

- Grease and fit double-taper sleeve

- Place encoder over double-taper sleeve and tighten screw (8.49) - max.

tightening torque 17 Nm

- Align spring clip (8.29) so that protruding straight end is the greatest

distance radially from motor rotor

- Fix spring clip eyes at each end with a washer (8.46) or wire lug and

screw (8.47 / 8.48); initially tighten screws to 0.5 Nm - the spring clip

should not be under tension - then tighten to 0.8 - 1 Nm with a torque

wrench

- Secure screws (8.47 / 8.48), e.g. with Loctite 243

NOTE: When fitted, the spring clip must not be in contact with the

cover/connector under any circumstances

- Check adjustment of speed sensor and rotor position encoder and

readjust if necessary

- Check max. radial run-out for one revolution!

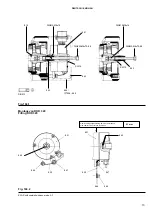

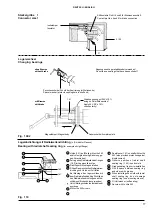

3.4.2 ROD 426 (8.900)

Removing (see Fig. 105)

- Remove threaded sealing cap (8.914)

- Release screw (X1) in coupling (8.920)

- Release screws (8.903) and turn claw (8.901) out of encoder centring

hole

- Pull off encoder (8.900)

NOTE: When pulling the encoder off, make sure that the coupling discs

are not overstressed or damaged

- Remove flange (8.910)

- Remove conical shaft (8.922) using 12 mm spanner, holding speed

sensor rotor with 19 mm spanner at the same time! - max. torque 30Nm

NOTE: Do not damage locating pin (8.16)

Fitting

- Grease and fit conical shaft

- Max. tightening torque for conical shaft (8.922): 10 Nm, and for the

screw (X1): 0.5 Nm

- After refitting the conical shaft (8.922), check the speed sensor and

rotor position encoder for correct adjustment and replace if necessary

- Check max. permissible run-out and eccentricity deviation

- Apply sealant (e.g. Fluid D) to sealing face D on the encoder centring

hole and screws (8.903)

3.4.3

Absolute value encoder without limit

switch gearbox (8.930)

Removing and fitting, see 3.4.2 ROD 426

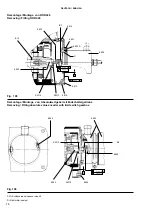

3.4.4

Absolute value encoder with limit switch

gearbox (8.930)

Removing (see Fig. 106)

- Remove threaded sealing cap (8.944)

- Release screw (X1) in coupling (8.950)

- Remove screws (8.942)

- Pull off encoder (8.930)

- Remove taper shaft (8.952) using 12 mm spanner, holding speed

sensor rotor with 19 mm spanner at the same time

Fitting

- Max. tightening torque for conical shaft (8.952): 10 Nm, and for the

screw (X1): 0.5 Nm

- After fitting the conical shaft, check the speed sensor and rotor

positional encoder for correct adjustment and replace if necessary

- Check max. permissible run-out and eccentricity deviation!

3.5

Removing / Fitting the

tachogen

pos. encoder, resolver

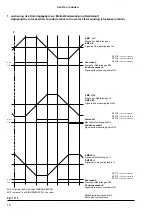

3.5.1

Tachogen rotor pos. encoder

Removing (see Fig. 107)

- Remove screws (6.48) and cover (6.25) if necessary

- Release connector

- Mark position of switching disc (8.02) relative to N-end endshield

- Release screws (6.45) and remove switching disc

- Remove screw (6.49 - fixing tachogenerator to motor rotor) if necessary,

prevent motor rotor from turning at the same time by holding with 19 mm

spanner on the tachogenerator hub

- Screw in DIN913 M6 x 20 grub screw (protects centring hole in end of

shaft)

- Screw in DIN933 M8 x 70-8.8 screw in tachogenerator rotor and push

tachogenerator off motor rotor - prevent motor rotor from turning at the

same time - max. torque 20 Nm

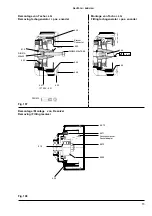

Fitting

- Push on tachogenerator rotor until the locating pin (8.16) engages in the

slot

NOTE: Do not damage locating pin (8.16)

- Max. tightening torque for the screw (6.49): 17 Nm, and for 6.45-

1FT506.: 0.7 Nm

- Check adjustment and re-adjust if necessary

- Check max. permissible radial run-out of tachogenerator rotor

- Screw down cover

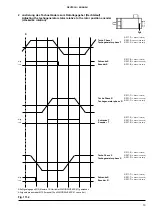

3.5.2 Resolver

(8.960)

Removing (see Fig. 108)

- Unscrew cover (8.970)

- Mark position of resolver stator relative to N-end endshield (6.20) in

order to simplify subsequent adjustment of encoder system

- Release intermediate connector

- Remove nut (8.972) from motor rotor, prevent motor rotor from turning

at the same time by holding D-end of shaft

- Remove resolver attaching screws (8.971) from N-end endshield

- The resolver rotor and stator can now be pulled off by hand

Fitting

- Push on resolver rotor until the locating pin (8.16) engages in the slot

NOTE: Do not damage locating pin (8.16)

- Screw on nut (8.972) - prevent motor rotor from turning at the same time

- max. tightening torque 12 Nm

- Refit resolver stator and fix with screws (8.971)

- Connect up intermediate connector

- Check adjustment and re-adjust if necessary

- Screw down cover

○

○

○○○○○○○○

9

ENGLISH