9

Troubleshooting

9.1

General faults, warnings, and errors

Possible errors and corrective actions are described in the table below. In the case of

errors that cannot be corrected using the information below, please contact the SICK

Service department. To find your agency, see the back page of this document.

NOTE

Before calling, make a note of all type label data such as type designation, serial num‐

ber, etc., to ensure faster telephone processing.

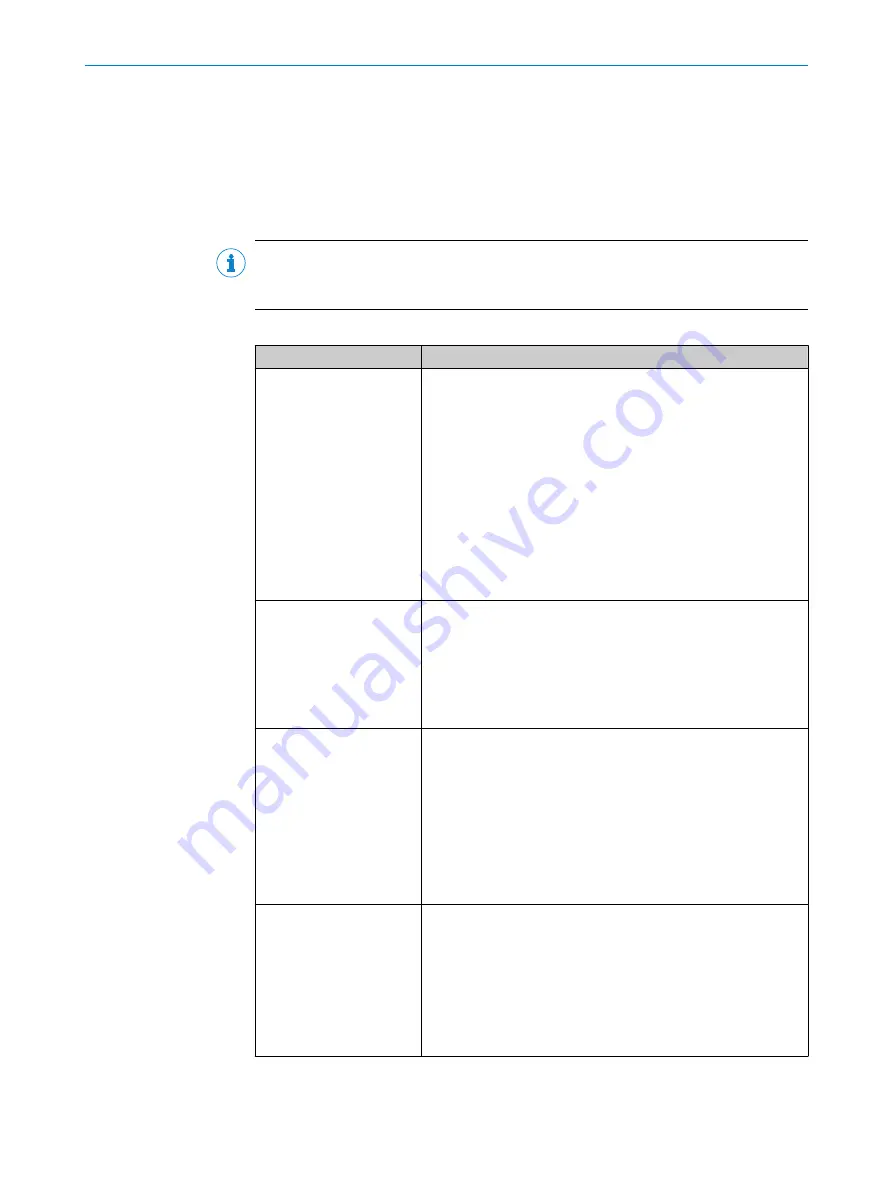

Table 11: Troubleshooting questions and answers

Question

Possible cause and resolution

The result is invalid.

The

Shape

,

Plane

,

Edge

and

Peak

tools require image data inside

their region of interest to work.

b

In Job mode, make sure that the regions of interest are placed

correctly in 3D space.

The

Shape

tool is unable to find any edges inside its region of inter‐

est.

b

Try increase the robustness slider, or include a larger portion of

the image for the

Shape

tool.

For a

Shape

tool, the result might become invalid if the Profile dis‐

tance parameter is changed after the job image is saved. If a

Shape

tool result is invalid, the results for all tools linked to it will

also be invalid.

The laser LED is on, but

there is no laser.

The laser module has a protection circuit and will shut itself down

if it detects a voltage spike. Such a voltage spike is common if the

TriSpector1000 is powered on by mechanically plugging in an

already powered 24 V contact into the device.

b

When all cables are connected, make sure that the power

source is stable and that a power switch is used to power

on the TriSpector1000.

The

Shape

tool does not

find the object, it returns

"Not Found".

The object contains areas with noise, or areas which change from

sample to sample.

b

Only use the

Shape

tool on edges that are present in all live

images.

b

In the tool parameter pane, in the

Masks

section, apply a mask

to exclude unwanted parts of the object.

b

Increase the robustness of the

Shape

tool.

b

Decrease the edge threshold of the

Shape

tool to include more

edges for matching. Do not include noise or areas that can

change.

A reflective surface reflects

the laser light, so it is diffi‐

cult to get a good image.

Tilt the TriSpector1000 to adjust the camera-laser angle.

b

To get more data from reflective surfaces, tilt the TriSpec‐

tor1000 forward. A more specular camera-laser angle will

result in more light entering the camera.

b

To avoid noise due to a reflective surface, tilt the TriSpec‐

tor1000 backwards for a more look-away camera-laser angle.

The TriSpector1000 coordinate system also tilts when tilting the

device, so height measurements in mm are no longer valid.

TROUBLESHOOTING

9

8021808/12ID/2019-01 | SICK

O P E R A T I N G I N S T R U C T I O N S | TriSpector1000

59

Subject to change without notice