For more information about how to work with the protective device, refer to the machin‐

ery documentation or the operating instructions for the protective device.

You can call

up the EU declaration of conformity and the current operating instructions for the pro‐

tective device by entering the part number in the search field at

(part

number: see the type label entry in the “Ident. no.” field).

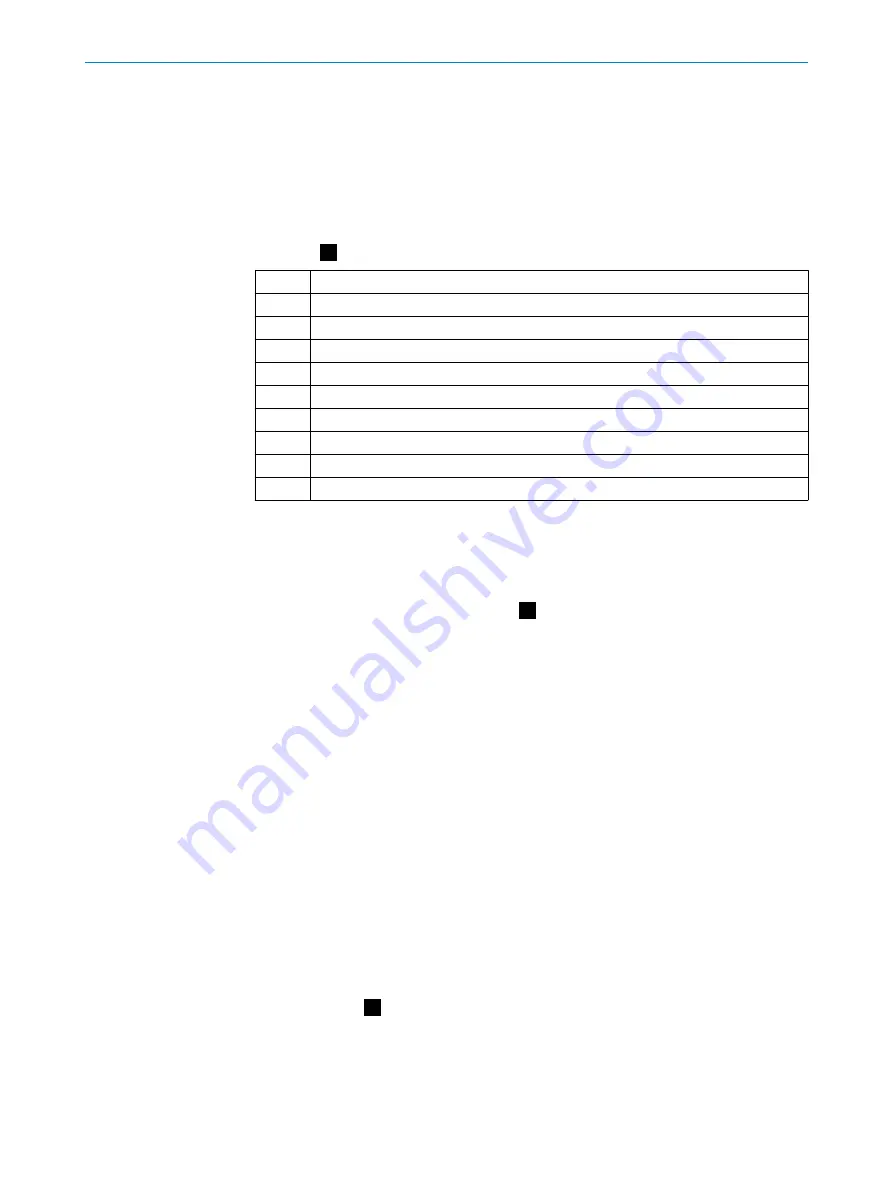

3

Device overview

Overview:

1

Optics cover

2

Display

3

Keypad

4

USB port

5

Status LEDs

6

Additional LEDs for ON state and OFF state

7

Network LEDs

8

Safety laser scanner without system plug

9

System plug

ß

Cover plate

The USB connection (USB 2.0 Mini-B, female connector) may only be used temporarily

and only for configuration and diagnostics.

4

Changing position of the system plug

Changing the position of the system plug:

The system plug is installed at the bottom or rear when the safety laser scanner is deliv‐

ered. You can change the position of the system plug if needed.

Tool required:

•

TX20 Torx wrench

Approach

1.

Loosen the screws of the system plug.

2.

Carefully remove the system plug from the safety laser scanner.

3.

Loosen the cover plate screws.

4.

Remove the cover plate from the safety laser scanner.

5.

Carefully slide the new system plug into the safety laser scanner at the desired

position (bottom or rear).

6.

Screw in the system plug using the captive screws. Tightening torque: 2.25 Nm …

2.75 Nm.

7.

Install the cover plate on the safety laser scanner. Tightening torque: 2.25 Nm …

2.75 Nm.

5

Mounting the safety laser scanner directly

Direct mounting:

The safety laser scanner has 4 M5 threaded holes on the back. If you are able to drill

through the mounting surface from the rear, you can mount the safety laser scanner

directly using these threaded holes.

MOUNTING INSTRUCTIONS

12

M O U N T I N G I N S T R U C T I O N S | microScan3 – EtherNet/IP™, microScan3 – EFI-pro, microScan3 – PROFINET (M12)

8020210/14BK/2019-07-04 | SICK

Subject to change without notice