Operating Instructions

Chapter

7

CLV 480 Bar Code Scanner

8 010 080/O824/10-02-2005

©

SICK AG · Division Auto Ident · Germany · All rights reserved

7-1

Maintenance

7

Maintenance

7.1

Cleaning the CLV during operation

To ensure optimum reading performance, the reading window of the CLV must be clean at

all times. For this reason, we recommend that you check the reading window at regular

intervals, particularly if the device is operated under extreme conditions (dust, abrasion,

humidity, finger prints).

Laser beam can cause blindness.

The CLV uses a class 2 red-light laser. Looking directly at the laser beam can seriously

damage your eyesight.

¾

Never look directly into the path of the beam (similar to sunlight).

¾

Switch off the device while it is being cleaned.

¾

Never look directly into the reading window while the device is in operation.

Damage on the reading window

The reading window is made of glass. Scratches and streaks on the window will reduce the

reading performance.

¾

Use a mild, non-scouring detergent.

¾

Never use scratching or scouring motions to clean the reading window.

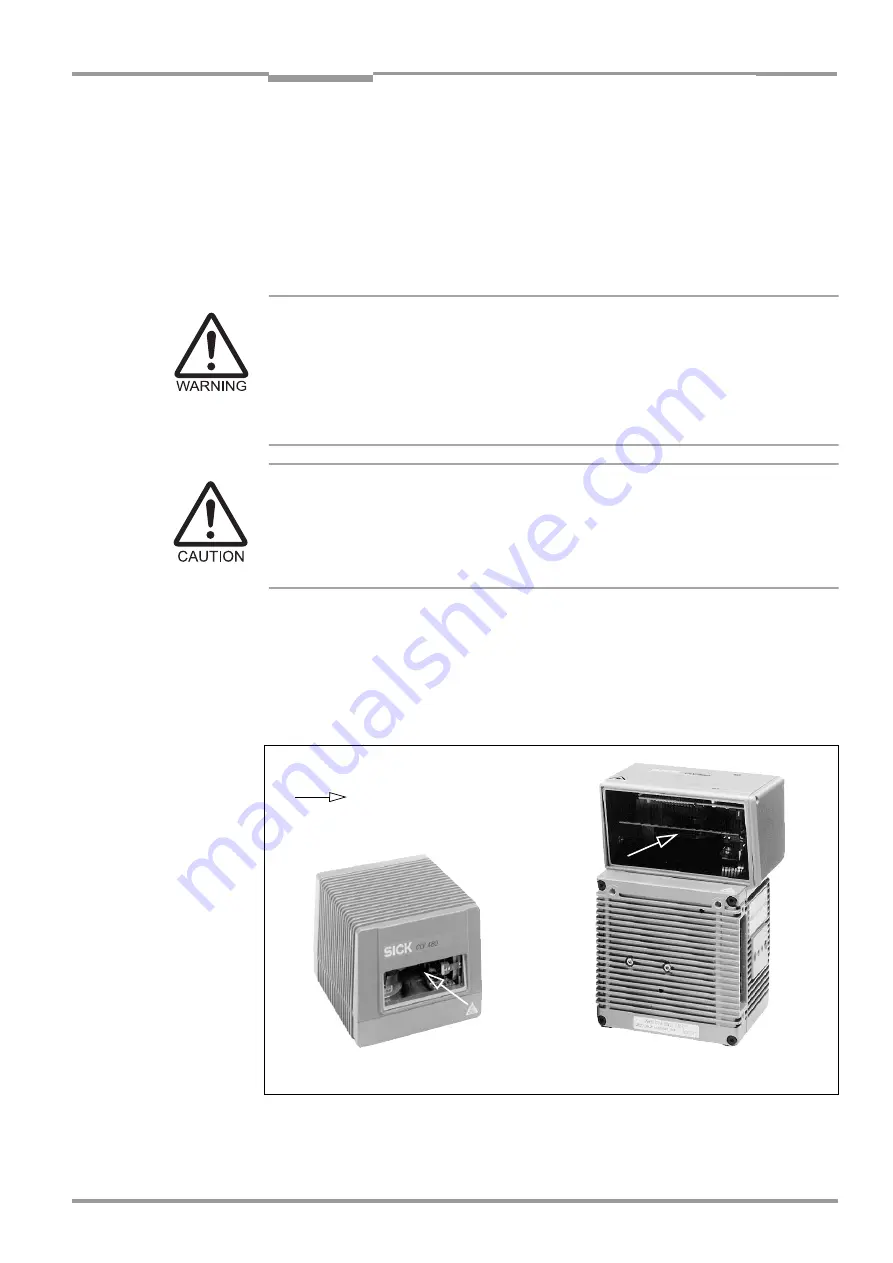

Cleaning the reading window:

¾

Clean the reading window at regular intervals with a mild, non-scouring detergent, e. g.

an antistatic glass cleaning fluid.

shows the areas that require cleaning. Use

soft, lint-free cloth.

¾

If necessary, clean the LEDs on the rear of the device.

Note

Don’t open the device. The producer warranty will be forfeited if the device is opened.

Fig. 7-1:

Cleaning the reading window

Side reading window

Front reading window

Clean here