- 10 -

◼

Chapter 5

Maintenance and inspection

Perform maintenance and inspections to prevent malfunctions and accidents and

ensure long life of this machine Be sure to turn off the power supply before inspecting

internally. While performing maintenance and inspection work or replacing the filter cloth,

wear protective glasses, a dust mask, and gloves.

If this machine falls under the

Industrial Safety and Health Act (Organic Solvent

Ordinance, Lead Ordinance, Specified Chemicals Ordinance, Dust Ordinance), inspect

this machine according to the periodic self-inspection guidelines specified by law.

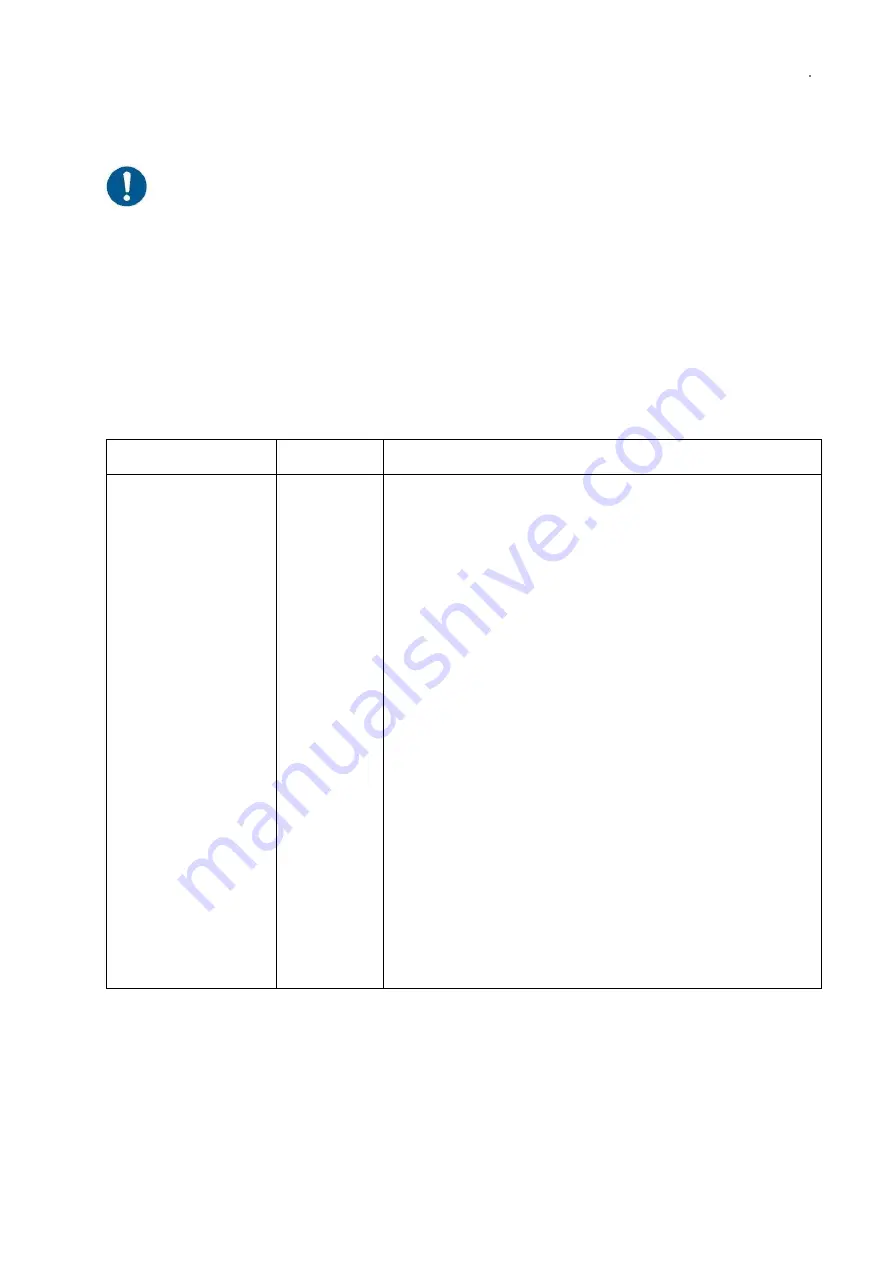

Inspection item and frequency

Inspection item

Frequency

Inspection details

Front door

Before

operation

Is the door closed completely?

Dust pan

Have collected materials been discharged?

Motor load current

Once/day Inspect by ammeter on control panel, etc.

Exhaust condition

Is there any dust leak through the filter?

Vibration of blower

Is there no abnormal vibration or abnormal sound?

Shaking device

Is there no abnormal sound or malfunction?

Filter cloth

attachment

Once/month Is there no detachment, looseness, breakage, etc.?

Each electric wiring

Is insulation proper? Is there no looseness in the

terminal?

Inside of main body

r

Clean stuck materials or powder.

(Increase inspection frequency depending on use)

Main body

Once/year Is there no corrosion or apertures/gaps/cracks?

●

When cleaning the outer or inner surface of the main body, wipe it with a waste cloth soaked

in water or a neutral detergent. Wiping with a solvent such as paint thinner may cause peeling

or discoloration of the coated surface.