-58-

Df[\cN(/(0&N(/)'=fiDXZ_`e\jD]^%J`eZ\*&('

FG

<

I

8

K@FEJ

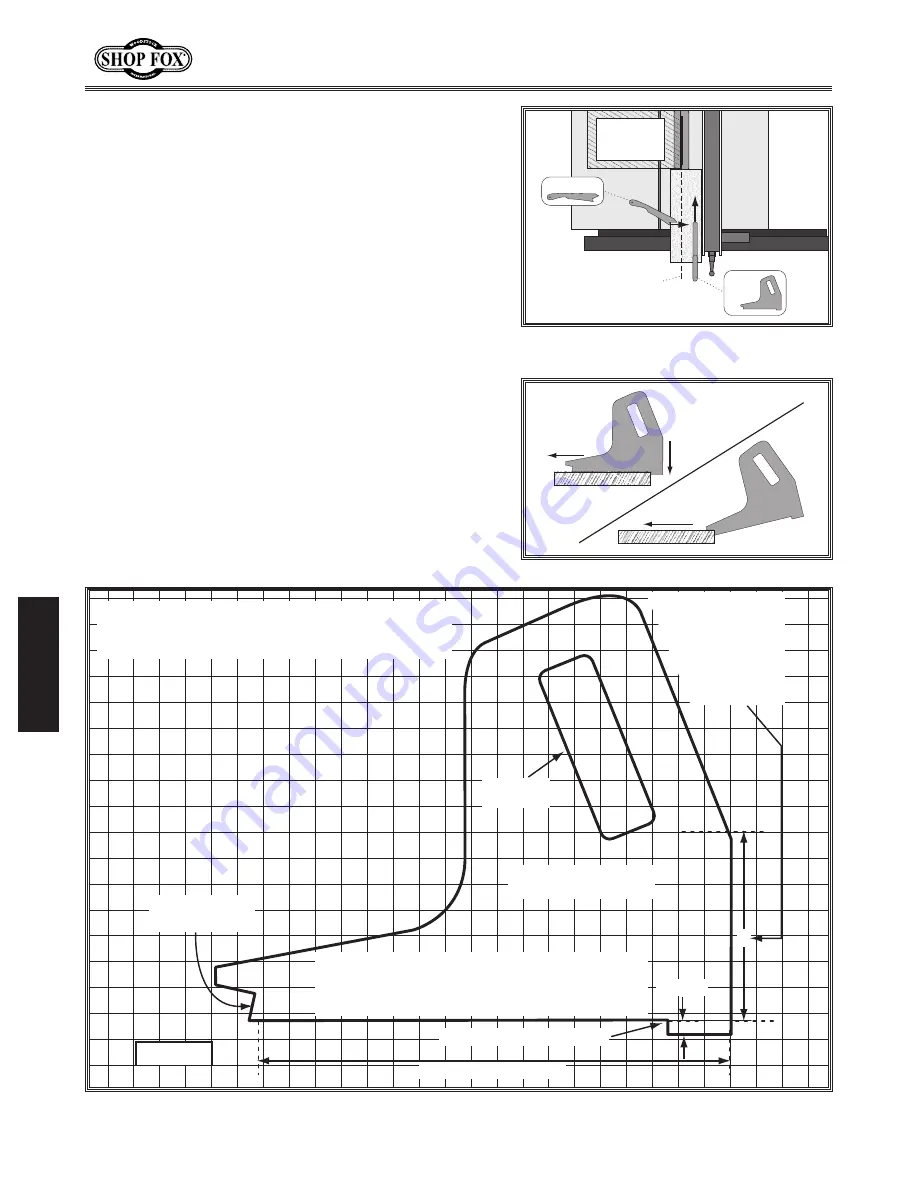

Glj_9cfZbj

When used correctly, a push block reduces the risk of

injury by keeping hands away from the blade while

cutting. In the event of an accident, a push block often

takes the damage that would have otherwise happened

to hands or fingers.

A push block can be used in place of or in addition to

a push stick for feeding workpieces into the blade. Due

to their design, push blocks allow the operator to apply

firm downward pressure on the workpiece that could not

otherwise be achieved with a push stick.

The push block design on this page (see

=`^li\

80

) can

be used in two different ways (see

=`^li\

79

). Typically,

the bottom of the push block is used until the end of the

workpiece reaches the blade.

The notched end of the push block is then used to push

the workpiece the rest of the way through the cut,

keeping the operator's hands at a safe distance from the

blade. A push stick is often used at the same time in the

other hand to support the workpiece during the cut.

=`^li\.0

. Side view of push block in use.

Blade

Path

Push Stick

Push

Block

Push Stick

Prohibition

Zone

Feeding

Supporting

=`^li\./%

Using a push block and push

stick to make a rip cut.

9"−10" Minimum Length

Lip for pushing workpiece

Handle for

firm grip

Make push block with

1

⁄

2

"–

3

⁄

4

" thick material

1

⁄

4

"–

1

⁄

2

"

4"

Notch for use

as a push stick

1

⁄

2

" Grid

CAUTION:

Only use hardwood, sturdy plywood, or

high-density plastic. Do not use softwood that

may break under pressure or metal that can break

teeth from the blade!

CAUTION:

Bottom

of handle must be

at least 4" above

bottom of push

block to keep

hand away from

blade.

=`^li\/'

. Template for a basic shop-made push stick (not shown at actual size).

DXb`e^XGlj_9cfZb

Use this template to make your own push block.