3

Antenna Installation

2

Antenna Installation

Precautions

WARNING

Don't expose personnel to the medical hazards of intense radio fre-

quency (RF) radiation. Whenever working on the tower in the area of

the antenna, turn off all transmitters and lock them out so that they can-

not be turned on accidentally.

Installing the support

pipe

The 6812DIN antenna is designed to mount on a customer-supplied vertical

pipe, which in turn is mounted on the tower. Mounting is a little different for

side-mounted poles and top-mounted poles.

The pipe must be between 2-3/8” and 3-1/2” (60 and 89 mm) nominal out-

side diameter. It must extend at least five feet (1500 mm) above the top bay

and five feet below the bottom bay.

NOTE

Shively can accommodate other pipe sizes if necessary by special order.

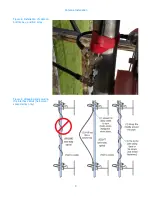

Side-mounted support pipe

Mount your support pipe securely as shown in

. It must stand off from

the tower as described in

Figure 1. Support pipe

installation

Follow these guidelines:

a. To ensure good electrical contact between the support pipe and the tower,

remove the tower paint and any rust at the support pipe mount locations

before installing the mounts. After installing the mounts, be sure to touch up

the paint where you removed it.

b. Starting at the top of the support pipe, mark the location of each bay in

accordance with the installation drawing.

c. Also, mark the specified location of any accessory mounts (eg: de-icer box

mounts), to make sure they will fit as planned.

Table 3. Side-mounted support pipe standoff from tower

Tower Face "A"

Standoff "B"

less than 24" (610 mm)

12" (305 mm)

24" - 60" (610 - 1500 mm)

24" (610 mm)

over 60" (1500 mm)

36" (915 mm)

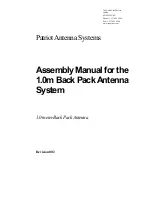

CAUTION

If you don't get good elec-

trical contact between the

mounts, the support pipe,

and the tower, the

antenna may not perform

as designed and may pro-

duce stray signals that will

interfere with other ser-

vices on the tower.

Important

Improper antenna mount-

ing is a leading cause of

poor

performance

in

6812DIN antennas. It is

very important to install

the antenna as indicated

and to position it away

from other metallic struc-

tures.