49(53)

2) When the machine stops due to faults, press down the main power switch first

(the alarming light goes out), then check the cause of the faults, the machine

should not be started forcibly before troubleshooting.

3) Do regular inspection inorder to prolong the lifespan of the system and avoid

the happening of accidents.

4) Because the high alkalescence will accelerate the rusting of copper pipe and

decrease the lifespan of the heat exchanger so it needs to do water quality

dispose for the system used water, the water PH value should be within the

range from 7.0 to 8.5.

5) Keep the machine room dry, clean and have good ventilation.

6) The daily operation, management and maintenance work should be carried

out by professionals. (Please notice that any disassembly or check during the

operation will be dangerous!)

7) In order to make sure the chiller is under good working performance, the user

should clean the condenser and evaporator timely to avoid furring

accumulation, and affect its heat exchange.

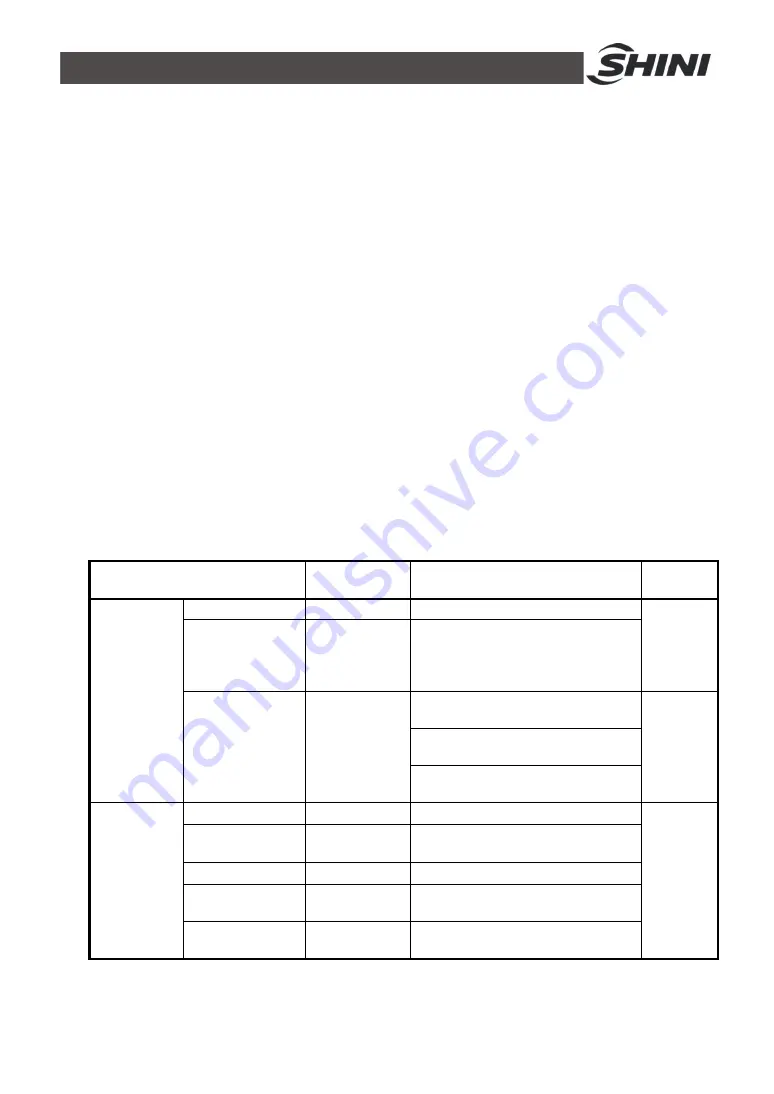

6.1

Maintenance Ltems

Maintenance item

Times

Qualification

standard(treatment)

Remark

Noise

Any time

Judge by listening

Vibration

Any time

Observe the tubing of the unit body

and parts to see if there is over

vibrating phenomenon

Stand 1

m ahead

of central

unit to

observe

Voltage when stops should be

±

10%

within rated voltage

Voltage when running should be

more than

±

10% of rated voltage

General

Power voltage

Any time

Voltage when starts should be more

than 85% of rated voltage

Clean

Any time

Keep clean at any time

Rust-cleaning

Any time

Clean the rust with iron brush

,

then

paint it with anti-rust paint

Balance

Any time

Lock up screws of every parts

Heat resistance

material scale off

Any time

Glue it with new adhesive

Out

appearance

of machine

Water leakage

1 time/month

Clean dew dish, do not let drainage

pipe be clogged