7

Ground Wire

Terminal

Ground

Wire

Assembly

Throttle Linkage and Ignition Leads

(continued)

Assemble and Adjust

the Throttle Cable.

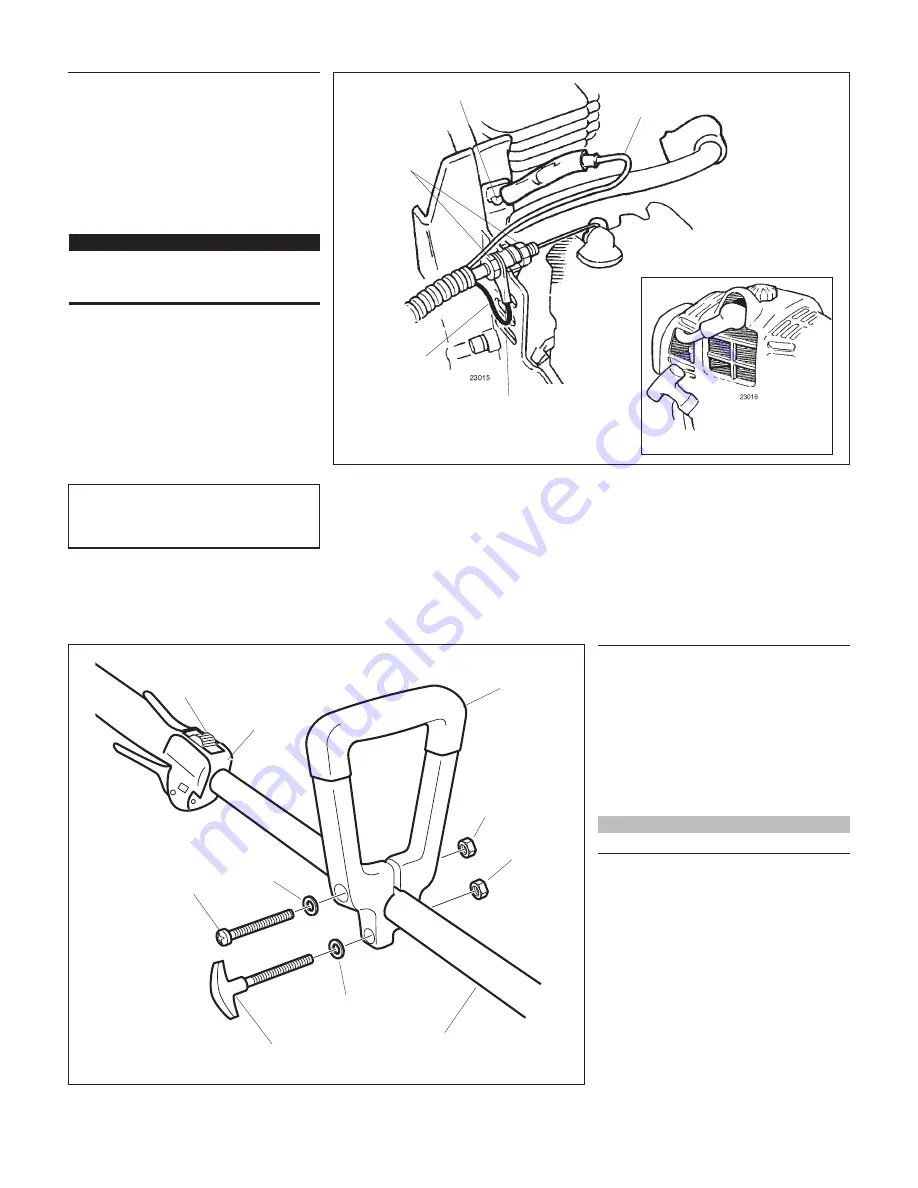

1. Insert the throttle-cable housing into the

notch on the fan cover, and clamp the

ground wire terminal between the fan

cover and the outer cable adjuster nut.

See Figure 10.

2. Tighten the two throttle cable adjuster

nuts.

IMPORTANT!

Adjust and tighten the cable nuts to allow

approximately 1/4-inch free play at the

throttle trigger.

CAUTION!

Routing of wiring must not interfere with

throttle operation.

Figure 10

Reinstall the Spark

Plug Cap

Black Ignition

Wire

Red Wire

Cable Adjuster

Nuts

3. Using finger pressure only, connect

the black ignition wire from the cable

tube to the red ignition wire on the

powerhead. Wire routing must be as

shown in the illustration with the black

wire located away from the throttle cable

and carburetor linkage.

4. Reinstall the engine cover and tighten

the captive engine cover screw.

5. Reinstall the spark plug boot.

23028

Assembly

Handle

1. Remove both screws from the handle.

2. While spreading the handle at the

mounting hole, position the handle on

the outer tube as shown.

3. Reinstall the two mounting screws in the

handle, but do not tighten them at this

time.

NOTE:

The handle is recessed to receive the hex nuts.

4. Locate the handle at the best position

for operator comfort (usually about 10

inches ahead of the throttle assembly).

5. Secure the handle by tightening the

mounting screw and the adjustment

knob screw.

Handle

Hex Nut

Washer

Hex Nut

Outer Tube

Adjustment

Knob

Mounting Screw

Washer

Connect the Handle to the

Outer Tube.

Figure 11

Throttle

Assembly

Ignition

Switch

Summary of Contents for LE230

Page 18: ...18 NOTES...

Page 19: ...19 NOTES...