6

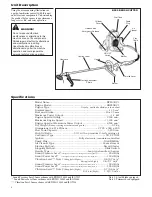

Specifications

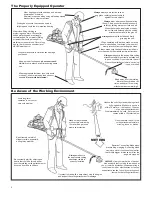

Unit Description

Caution Label

Barrier

Cutting Attachment

Shield

Using the accompanying illustrations as

a guide, familiarize yourself with this unit

and its various components. Understanding

the product helps ensure top performance,

long service life, and safer operation.

WARNING!

Do not make unauthorized

modifications or alterations to this

machine or any of its components.

Shindaiwa must authorize alterations

and modifications in writing.

Unauthorized modifications or

alterations may alter the machine

operation and could jeopardize

personal safety during operation.

ON-OFF

Switch

Gearcase

Harness with

Emergency Release

Spark

Plug

BP45 BRUSH CUTTER

Model Name .............................................................................BP45/EC1

Engine Model .......................................................................... SBP45EC1

Engine Type ..........................................

2-cycle, vertical-cylinder, air-cooled

Displacement .............................................................................

41.5 cm

3

Bore and Stroke ......................................................................

40 x 33 mm

Maximum Power Output ................................................................

1.4 kW

Engine Speed at Idling ............................................................

2,500 min

-1

Maximum Engine Speed ........................................................

11,500 min

-1

Engine Speed at Maximum Power Output ...............................

6,500 min

-1

Dry Weight

(Without cutting attachment and guard)

...................................9.7 kg

Dimensions (L x H x W) mm ......................................... 2,720 x 365 x 405

Fuel Tank Capacity ...................................................................1,400 cm

3

Fuel/Oil Ratio .............................. 50:1 with a premium 2-cycle mixing oil

Carburetor Type .................................................................... TK, PC1OW

Ignition ..............................................

Fully electronic, transistor controlled

Spark Plug ........................................................................... NGK BMR6A

Air Cleaner Type .................................................................Foam element

Starting Method .................................................................. Recoil Starter

Stopping Method .................................................................. Slide Switch

Handle Type .................................................. Loop type handle w/barrier

Sound Pressure Level*

(average data between at Idling and at Racing) Note 1

............. 83 dB (A)

Sound Power Level**

(average data between at Idling and at Racing) Note 1

........... 103 dB (A)

Vibration Level*** Note 1

Idling (Left/Right)

...............................0.6/0.7 m/s

2

Racing (Left/Right)

2.6/2.7 m/s

2

Sound Pressure Level*

(average data between at Idling and at WOT) Note 2

............... 93 dB (A)

Sound Power Level**

(average data between at Idling and at WOT) Note 2

............. 105 dB (A)

Vibration Level*** Note 2

Idling (Left/Right)

...............................0.7/0.6 m/s

2

WOT (Left/Right)

1.4/2.0 m/s

2

* Sound Pressure Level: In accordance with EN ISO 14865 and ISO 7917

** Sound Power Level In accordance with EN ISO 14865 and ISO 10884

*** Vibration Level: In accordance with EN ISO 14865 and ISO 7916

Note 1: 8-tooth blade equipped.

Note 2: Trimmer head equipped.

Throttle Lever

Flex

Cable

Fuel Tank

Muffler

Cylinder

Cover

Air

Cleaner

Handle