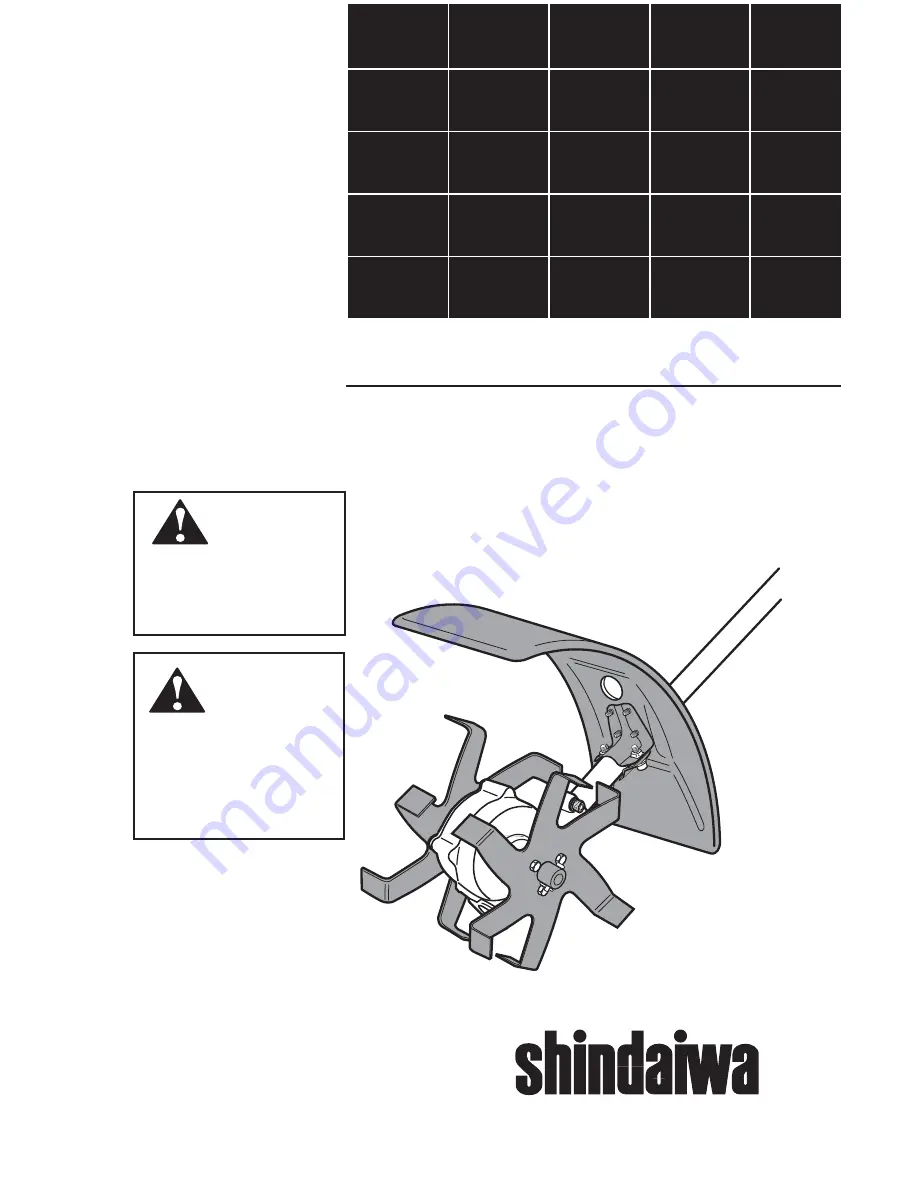

SHINDAIWA OWNER’S/

OPERATOR’S MANUAL

TILLER/CULTIVATOR

ATTACHMENT

Always wear eye and

ear protection when

operating this unit!

WARNING!

To minimize the risk of

injury to yourself and

others, read this manual

and familiarize yourself

with its contents.

WARNING!

Part Number 80465

䊛