3-2

109823 2/09

3.

Check the valve cap-contact surface for uneven

wear and streaks. If wear is insignificant, grind flat

with oilstone or grinder, otherwise, replace.

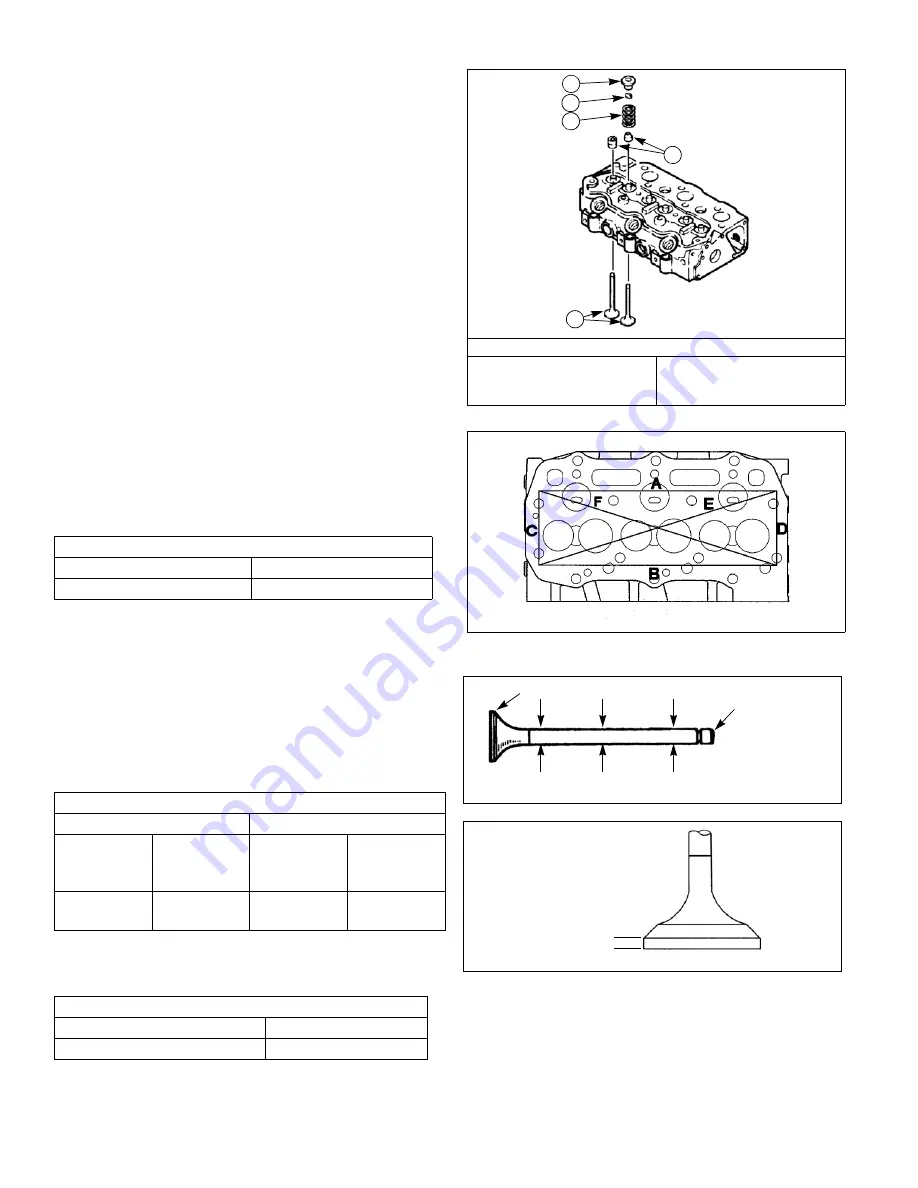

Cylinder head assembly

Disassembly

1.

Using a valve spring compressor, compress the

valve spring to remove the valve cotter, retainer,

spring and valve.

2.

Remove the valve guide seal.

Inspection and service

1.

Check for distortion of cylinder head bottom surface

by using a straight edge. Using Fig. 3-5 as a guide,

and a feeler gage, check for distortion at the six

positions—A through F. If distortion exceeds the

repair value, correct using a surface grinder.

2.

Valve guide and valve stem

a.

Check the head and stem of each valve and

replace if burned, worn, or deformation is

excessive.

b.

Measure the outside diameter at positions I, II, and

III on the valve stem with a micrometer and

replace if less than the service limit.

c.

Replace a valve if its head thickness is less than

service limit.

Distortion at cylinder head bottom surface in(mm)

Standard assembling value

Repair value

Less than 0.0020(0.05)

More than 0.0047(0.12)

Wear of valve stem ø in(mm)

Intake valve

Exhaust valve

Standard

assembling

value

Service limit

Standard

assembling

value

Service limit

0.274-0.2744

(6.955–6.97)

Less than

0.2712(6.89)

0.273-0.274

(6.94–6.955)

Less than

0.269(6.84)

Valve head thickness in(mm)

Standard assembling value

Service limit

0.0305-0.0423(0.775–1.075)

Less than 0.0197(0.5)

Fig. 3-4

1. Valve guide seal

2. Spring

3. Retainer

4. Valve

5. Valve cotter

1

2

5

3

4

Fig. 3-5

Fig. 3-6

Fig. 3-7

I

II

III

Stem End

Head End

Thickness

Summary of Contents for N843

Page 8: ...1 4 109823 2 09...

Page 11: ...109823 2 09 2 3 Engine Sectional Drawing...

Page 18: ...2 10 109823 2 09...

Page 46: ...109823 2 09 4 16...

Page 66: ...5 20 109823_2 09...