22

Problem: Rapid accumulation of creosote in furnace and flue.

• Use of high resin wood, such

as pine.

• Completely avoid using if at all possible. If hardwoods are not

available, fuel the furnace with smaller loads. This will cause

the thermostat to call for more heat more often, which will

initiate the running of the draft blower. Consequently, the fires

will be hotter, thereby reducing the accumulation of creosote.

Possible Causes:

Remedies:

• Under-firing the furnace has

caused low flue gas temperature.

• Install flue gas thermometer and maintain stack temperatures

between 300° and 400° F.

• See #9.

• Insufficient chimney draft.

8.

• Improper connection in stove

pipe causing air leakage or a

structural defect in the chimney

itself.

• Inspect entire flue run, from the exhaust stack of the furnace to the

termination cap. Repair as necessary.

• Fire box not receiving adequate

amount of oxygen.

• Chimney is not tall enough, see “10/2 Rule” on page 7.

• DANGER: Never use uninsulated stove pipe as chimney.

Uninsulated pipe cannot be used as an outside flue because it

causes rapid cooling of the stack gases, which causes them to

condense as creosote on the inside of the flue.

• Using uninsulated stove pipe for

the chimney.

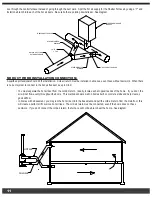

Problem: Smoke from the fire chamber is puffing back through the forced draft motor.

• Chimney is not high enough.

• Chimney should be a mininum of 6 feet high or refer to “10/2 Rule,”

see page 7 for details.

Possible Causes:

Remedies:

9.

Problem: Insufficient air flow from the heat registers.

• Return air not connected to

furnace from the house.

• Connect air to the home to circulate air flow.

Possible Causes:

Remedies:

• Excessive duct run to the house.

• Reduce duct run by placing the furnace closer to the house.

• Replace air filter.

• Air filter is dirty, restricting air flow.

10.

• The hot air supply is being short

cycled back through the return

instead of going down stream to

the house.

• Redirect the hot air supply to send it down the air duct supply line.

You may install a back draft damper from the direction of the return

air.

• If using flex duct, it is not straight

and pulled tight. A sagging line

will cause swirling in the duct and

reduct air flow.

• Ensure the flex duct is pulled tight and straight with no snags.

Always go into your main supply lines at a slant pointing down

stream.

• Remove 90° elbows and replace with 45° elbows.

• The use of 90° elbows in the duct

run.