10

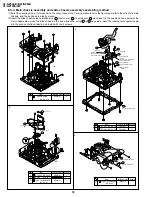

VL-NZ50S/H/E/W/NZ80H

VL-NZ100S/H/E

A

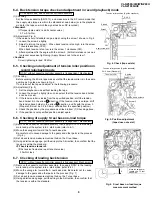

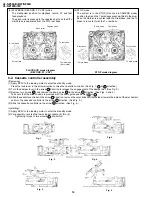

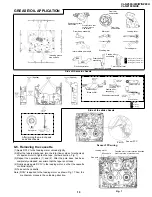

Fig. 7. Loading back tension measurement

method

Fig. 8. Winding Tu reel base ratchet torque

measurement method

Fig. 11

OK

NG

A

Fig. 10

Fig. 9

<REW back tension standard>

(If the tension fluctuates, read its center value.)

15

±

12mN

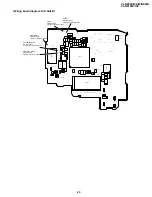

6-8. Checking of winding Tu reel base ratchet torque

DC3V, without cassette controller assembly (Independent Mechanism)

(1) Remove the cassette controller assembly, then apply DC3V to the loading

motor and put the system into standby mode. (refer to 8-1)

(2) Move the swing arm toward the S reel base side.

Be careful not to cause damage to the gears and other parts in the process.

(Fig. 8)

(3) Set a back tension measurement reel hub on the Tu reel base.

(4) Using a dial tension gauge, pull the string in the A direction, then confirm that

the tension is within the standard.

<Winding Tu reel base ratchet torque standard >

(If the tension fluctuates, read its center value.)

100mN or less

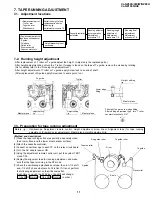

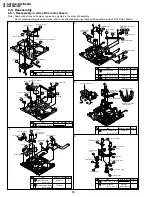

6-9. Checking of rewinding playback (VS-REW) back

tension

DC3V, without cassette controller assembly (Independent Mechanism)

(1) Remove the cassette controller assembly, then apply DC3V to the loading

motor and put the system into rewinding playback (VS-REW) mode. (refer to

8-1)

(2) Move the swing arm toward the S reel base side.

Be careful not to cause damage to the gears and other parts in the process.

(3) Set a torque gauge on the Tu reel base.

(4) Turning the torque gauge to counterclockwise (1 turn for 3 seconds), then

confirm that the torque is within the standard.

<Rewinding playback (VS-REW) back tension standard value>

(If the tension fluctuates, read its center value.)

0.70 +0.6/-0.3mN·m

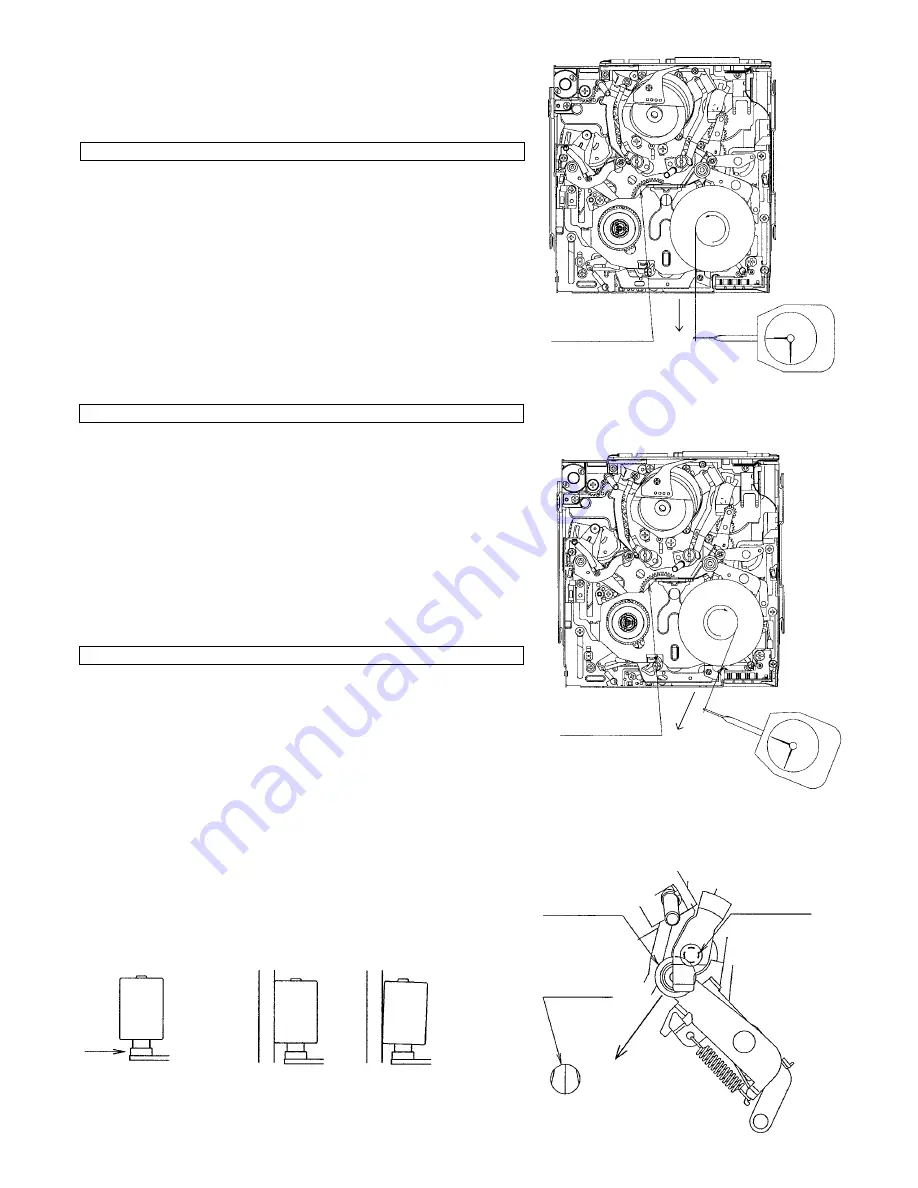

6-10.Checking of pinch pressing force

DC3V, without cassette controller assembly (Independent Mechanism)

(1) Set the pinch roller pressing force measuring thread on the pinch lever

(position A , Fig. 9).

(2) Set the mechanism to the playback mode, press the pinch roller against the

capstan shaft.

(3) Fit the tension gauge to the pinch roller pressing force measuring thread, pull

in the arrow B direction shown in Fig. 11 to separate a little the pinch roller from

the capstan shaft.

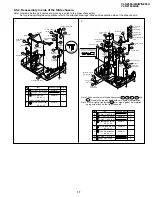

(4) Gradually return the pinch roller, and when the pinch roller contacts parallel

the capstan shaft, read the value (see Fig. 10) to make sure that the value

conforms to the standard shown below.

<Standard>

1.8 +0.3/-0.5N

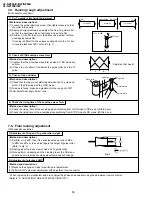

<Caution>

After making this measurement, quickly release the system from playback

mode and remove the pinch roller from the capstan shaft. (If the pinch roller

is left fitted onto the capstan shaft for a long time, the pinch roller will be

deformed.)

A

Move the swing arm

toward the S reel

base side.

Move the swing arm

toward the S reel

base side.

Capstan shaft

Pinch roller

B

Right guide