R-8000G

21

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

T

TOUCH CONTROL PANEL ASSEMBLY TEST

8. Reconnect all leads removed from components

during testing.

9. Reinstall the outer case (cabinet) and the back

plate.

10. Reconnect the power supply cord after the outer

case and the back plate are installed.

11. Run the oven and check all functions.

The following test procedure should be carried out with the microwave oven is a fully assembled

condition (outer case fitted).

It is difficult to measure the exact temperature in the convection oven. An accurate thermocouple type

temperature tester must be used. A low priced bi-metal type thermometer is not reliable or accurate.

The temperature should be checked with outer case cabinet installed, approx. 5 minutes after preheat

temperature is reached (audible signal sounds four times). The temperature experienced may be approx. 30˚F

more or less than indicated on the display, however, in most cases the food cooking results will be satisfactory.

Difference in power supply voltage will also affect the oven temperature. The Household power supply voltage

may sometimes become lower than the rated voltage (240 V) and cause under-cooking. If the power supply

voltage is 10% lower than the rated voltage, longer cooking time is required by 10% to 20%.

R

CHECKING TEMPERATURE IN THE CONVECTION MODE

The touch control panel consists of circuits including semiconductors such as LSI, ICs, etc. Therefore, unlike

conventional microwave ovens, proper maintenance cannot be performed with only a voltmeter and

ohmmeter.

In this service manual, troubleshooting by unit replacement is described according to the symptoms indicated.

Before testing,

1) Disconnect the power supply cord.

2) Remove the outer case cabinet, referring to "OUTER CASE CABINET REMOVAL".

3) Open the door and block it open.

4) Discharge high voltage capacitor.

5) Disconnect the leads to the primary of the power transformer.

6) Ensure that these leads remain isolated from other components and oven chassis by using insulation tape.

BLU

RED

WHT

Main Coil

3-pin

Connector

Sub Coil

Thermal

Cut-out

130˚C OFF

100˚C ON

100

Ω

110

Ω

JET MOTOR

1. Disconnect the power supply cord.

2. Remove the outer case cabinet, referring to "OUTER CASE CABINET

REMOVAL".

3. Open the door and block it open.

4. Discharge high voltage capacitor.

5. Disconnect the lead wires from the terminal the noise filter. Using an

ohmmeter, check between the terminals as described in the following

table. If incorrect reading are obtained, replace the noise filter.

6. Reconnect all leads removed from components during testing.

7. Reinstall the outer case (cabinet).

8. Reconnect the power supply cord after the outer case is installed.

9. Run the oven and check all functions.

S

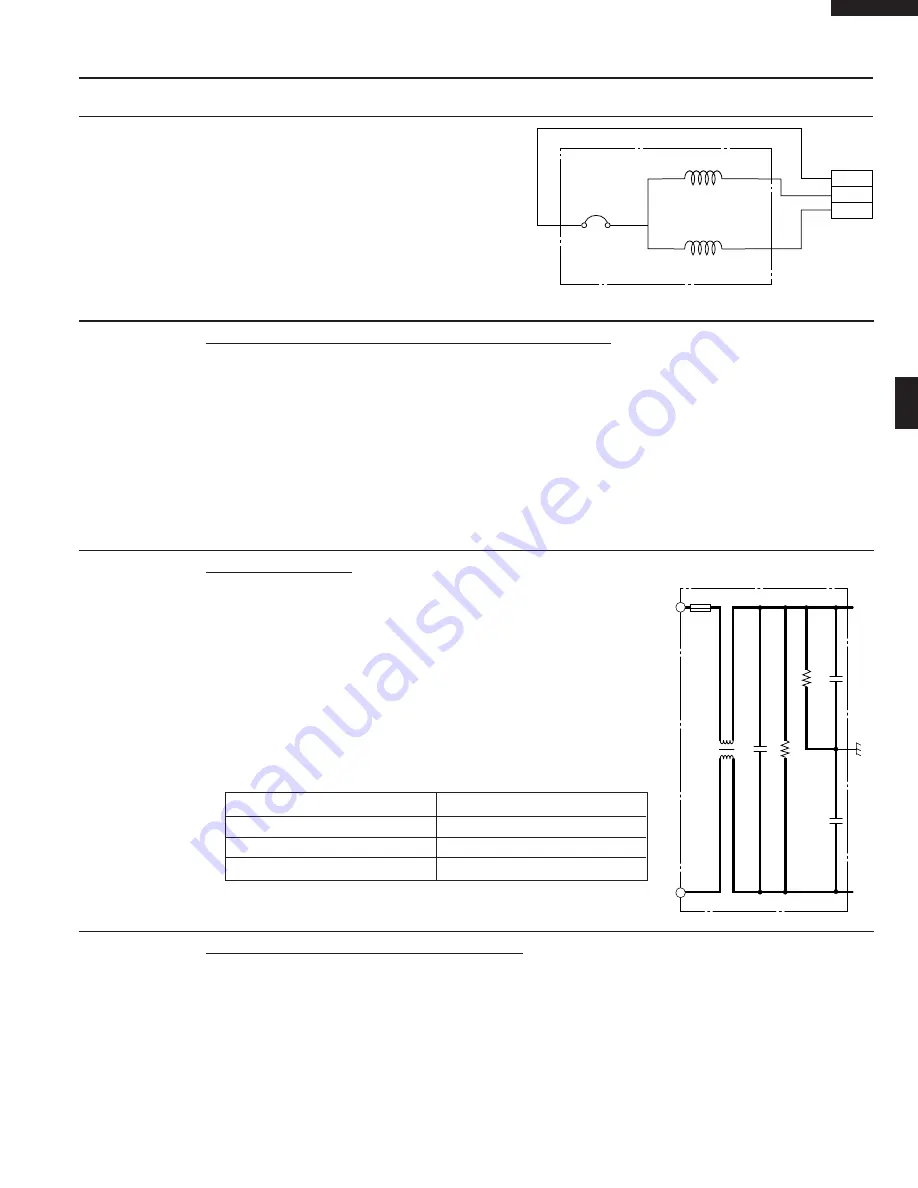

NOISE FILTER TEST

MEASURING POINT

INDICATION OF OHMMETER

Between L and L

Approx. 680 k

Ω

Between terminal L and RED

Short circuit.

Between terminal L and GRY

Short circuit.

NOISE SUPRESSION COIL

LINE CROSS CAPACITOR 1.0

µ

F 275V

RESISTO 680k

Ω

1/2W

RESISTO 10M

Ω

1/2W

LINE BYPASS CAPACITOR

0.0033

µ

F 250V

LINE BYPASS CAPACITOR

0.0033

µ

F 250V

MONITOR

FUSE

20A

BLK

WHT

GRY

RED

L

L