38

R - 4 0 5 K S

R - 4 0 3 K K

6

4

5

1

2

3

6

4

5

1

2

3

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

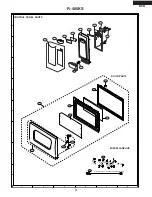

OVEN AND CABINET PARTS

2-3

4-7

6-5

1-4

4-6

4-8

4-9

6-3

6-2

2-1

7-5

1-9

4-10

7-2

7-2

7-4

4-3

1-10

1-7

7-3

7-6

7-5

7-6

4-2

7-4

1-8

7-1

1-6

1-6

4-4

7-1

4-1

1-1

1-2

2-2

2-2

2-2

2-2

7-4

7-4

4-11

7-4

6-4

1-11

7-4

7-7

7-4

7-7

1-5

1-3

4-5

7-4

7-4

1-13

4-12

1-12

1-5

R-405KS & R-403KK