26

R-2110JK

R-2110JW

R-2120JK

R-2120JW

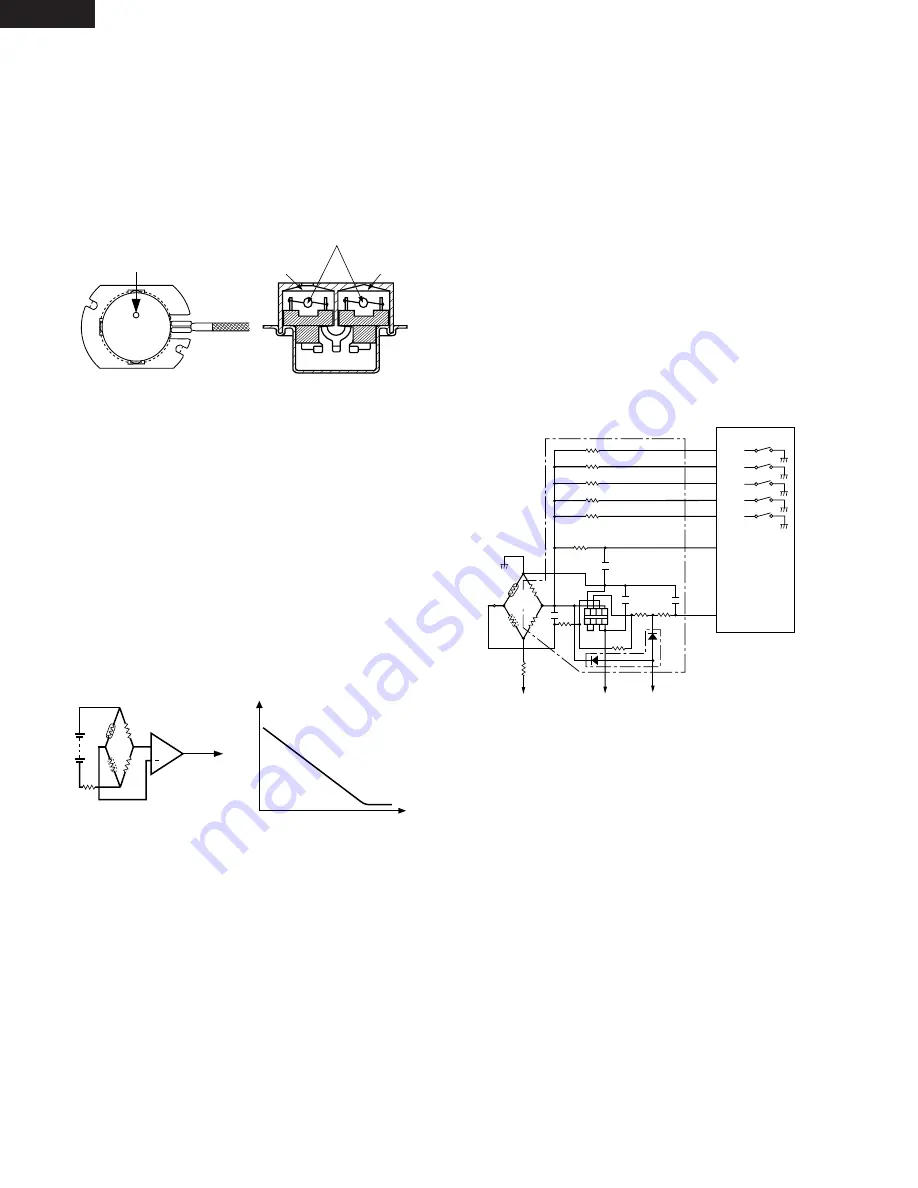

(1) Structure of Humidity Sensor

The humidity sensor includes two thermistors as shown

in the illustration. One thermistor is housed in the closed

vessel filled with dry air while another in the open vessel.

Each sensor is provided with the protective cover made

of metal mesh to be protected from the external airflow.

(2) Operational Principle of Humidity Sensor

The figure below shows the basic structure of a humidity

sensor. A bridge circuit is formed by two thermistors and

two resistors (R1 and R2).

The output of the bridge circuit is to be amplified by the

operational amplifier.

Each thermistor is supplied with a current to keep it

heated at about 150˚C (302˚F), the resultant heat is

dissipated in the air and if the two thermistors are placed

in different humidity conditions they show different

degrees of heat conductivity leading to a potential

difference between them causing an output voltage

from the bridge circuit, the intensity of which is increased

as the absolute humidity of the air increases. Since the

output is very minute, it is amplified by the operational

amplifier.

(3) Detector Circuit of Humidity Sensor Circuit

This detector circuit is used to detect the output voltage

of the humidity circuit to allow the LSI to control sensor

cooking of the unit. When the unit is set in the sensor

cooking mode, 16 seconds clearing cycle occurs than

the detector circuit starts to function and the LSI observes

the initial voltage available at its AN1 terminal.

With this voltage given, the switches SW1 to SW5 in the

LSI are turned on in such a way as to change the

resistance values in parallel with R98 ~ R102. Changing

the resistance values results in that there is the same

potential at both F-3 terminal of the humidity sensor and

AN0 terminal of the LSI. The voltage of AN1 terminal will

indicate about -2.5V. This initial balancing is set up

about 16 seconds after the unit is put in the Sensor

Cooking mode.

HUMIDITY SENSOR CIRCUIT

As the sensor cooking proceeds, the food is heated to

generate moisture by which the resistance balance of

the bridge circuit is deviated to increase the voltage

available at AN1 terminal of the LSI.

Then the LSI observes that voltage at AN1 terminal and

compares it with its initial value, and when the comparison

rate reaches the preset value (fixed for each menu to be

cooked), the LSI causes the unit to stop sensor cooking;

thereafter, the unit goes in the next operation

automatically.

When the LSI starts to detect the initial voltage at AN1

terminal 16 seconds after the unit has been put in the

Sensor Cooking mode, if it is not possible to balance the

bridge circuit due to disconnection of the humidity

sensor, ERROR will appear on the display and the

cooking is stopped.

1) Humidity sensor circuit

ventilation opening for sensing

Sensing part

(Open vessel)

Sensing part

(Closed vessel)

Thermistors

C

S

R3

R1

R2

+

Operational

amplifier

Output

voltage

S : Thermistor

open vessel

C : Thermistor

closed vessel

2

Absolute humidity (g/m )

Output voltage

Absolute humidity vs,

output voltage characteristic

SW1

SW2

SW3

SW4

SW5

P50

P51

P52

P53

P54

LSI

(IC1)

AN0

AN1

620k

300k

150k

75k

37.4k

18

15

14

10

9

16

17

47k

47k

15k

1 2 3 4

8 7 6 5

0.01uF

0.1uF

0.01uF

VA : -15V

VA : -15V

R90

C90

C91

C93

C92

S

F-2

1.8k

IC2

F-1

F-3

C

3.57k

3.32k

VC : -5V

0.1 uF

C. Thermistor in

closed vessel

S. Thermistor in

open vessel

R98

R99

R96

R91

360k

R93

R92

R94

R95

D90

R100

R101

R102

R97