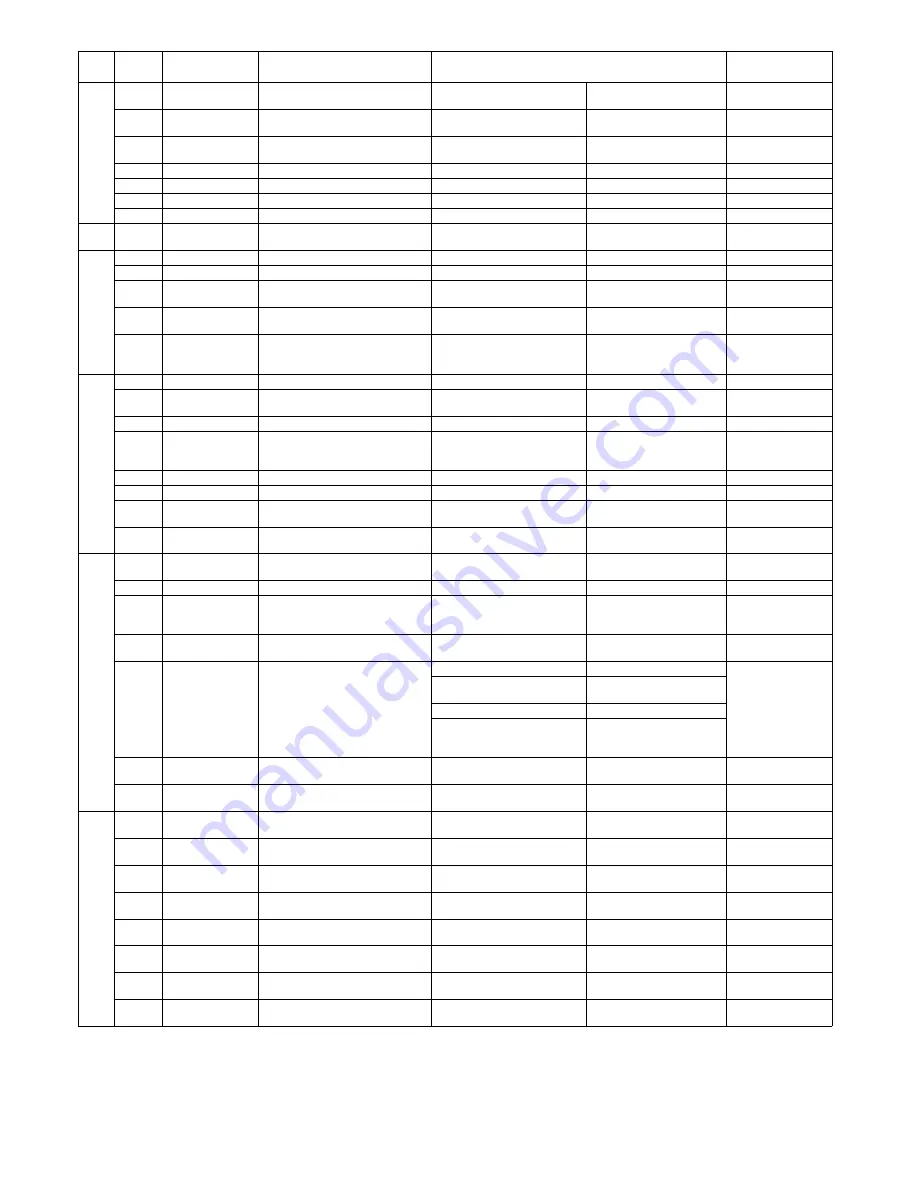

MX-C250 SIMULATION 6 – 74

42

1

Data output during communication

error

0 : Output

1 : Not output

2

Memory overflow during receiving

data

0 : Output

1 : Not output

3

Received data duplex printing set-

ting (list)

0 : OFF

1 : ON

4

Duplex printing tray (Tray 1)

0 : OFF

1 : ON

5

Duplex printing tray (Tray 2)

0 : OFF

1 : ON

6

Duplex rotated printing

0 : ON

1 : OFF

7 - 8

Not used

43-

44

Not used

45

1

Simulated ring bell sounds

0 : Sound

1 : Not sound

2

FAX initial setting

Digital line net setting

0 : OFF

1 : ON

3

Quick memory send setting display

0 : Displayed

1 : Not displayed

4

Manual send selection screen dis-

played

0 : Displayed

1 : Not displayed

5 - 8

Magnification setting in automatic

reduction

Setting range

0 - 15%

(100 - setting value)

46

1

Remote reception indication

0 : OFF

1 : ON

2

Remote changeover number set-

ting

0 : Only call-in

1 : Call-in/Call-out

3

Transfer function

0 : Prohibited

1 : Permitted

4

Specified number reception

Enable/Disable setting on manual

reception

0 : Ignore the specified num-

ber

1 : Reject the specified

number

5

Record of rejected reception

0 : Record

1 : Not record

6

Print in automatic reduction

0 : Prohibited

1 : Permitted

7

Priority order of the paper selec-

tion

0 : Priority area

1 : Priority width

8

Output way (Inch) when receiving

the A4 width image

0 : 210mm width printing

1 : 8.5inch width printing

47

1

Reception copy setting when

receiving the data

0 : Print out the copy when

receiving every one data

1 : Print out all copies after

receiving all copies

2

Report output (when cancelled)

0 : Output

1 : Not output

3

Report output (when refusing

reception)

0 : Output

1 : Convert name to the dial

number and print out

4

Address name of report conver-

sion

0 : Not convert

1 : Reject the specified

number

5 - 6

Range of the sound monitor

Speaker is always off.

0 0

Speaker is on while dialing and

handshaking; off in data mode.

0 1

Speaker is always on.

1 0

Speaker is off while dialing; on

during handshaking and

retraining.

1 1

7

Control of the communication error

sound

0 : Sound

1 : Not sound

8

The communication error sound

when there is no response

0 : Sound

1 : Not sound

48

1

FAX initial setting

Speaker volume after finishing

scanning (Small)

0 : Use volume 1

1 : Use volume 2

2

FAX initial setting

Speaker volume after finishing

scanning (Middle)

0 : Use volume 2

1 : Use volume 3

3

FAX initial setting

Speaker volume after finishing

scanning (Large)

0 : Use volume 3

1 : Use volume 4

4

FAX initial setting

Speaker volume during DTMF

sending (Small)

0 : Use volume 1

1 : Use volume 2

5

FAX initial setting

Speaker volume during DTMF

sending (Middle)

0 : Use volume 2

1 : Use volume 3

6

FAX initial setting

Speaker volume during DTMF

sending (Large)

0 : Use volume 3

1 : Use volume 4

7

FAX initial setting

Speaker volume of line monitor

(Small)

0 : Use volume 1

1 : Use volume 2

8

FAX initial setting

Speaker volume of line monitor

(Middle)

0 : Use volume 2

1 : Use volume 3

SW

No.

Bit

No.

System set-

tings

Item

SW selection and function

Remarks