MX3500N MX-RBX1, MX-FNX2 7 – 7

3)

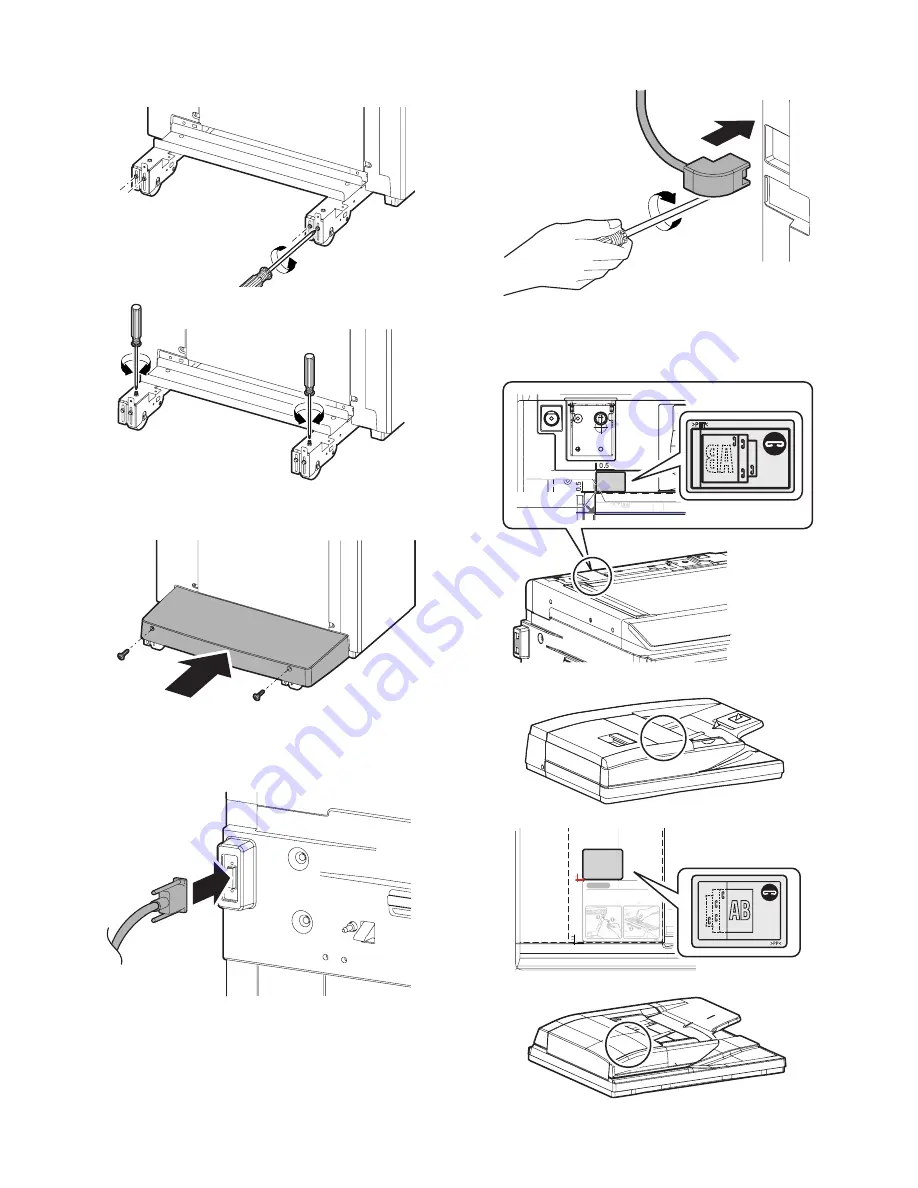

Loosen four fixing screws of the adjustment section, and turn

the height adjustment screws on the front/rear sides to adjust

so that the clearances are even.

4)

When the clearances are even, tighten the fixing screw of the

adjustment section, and install the foot cover.

F. Connector connection

1)

Connect the finisher connector with the connector of the inter-

face pass unit, and tighten the screw.

2)

Connect the finisher connector with the connector of the main

unit, and tighten the screw.

G. Staple position label attachment

1)

Attach the label to the position indicated in the figure.

[For scanner] (package part No. 8)

[For RSPF/DSPF] (package part No. 9)

Label attachment

reference

* Corner of the

"upper cabinet rear"

Corner R end fitting

Corner R end fitting

Cleaning of the document scan section

DSPF

RSPF

CAUTION

When streaks appear on copy or scan

images, open the automatic document

feed unit and clean the document scan

section with the glass cleaner (accessory).

Document scan section