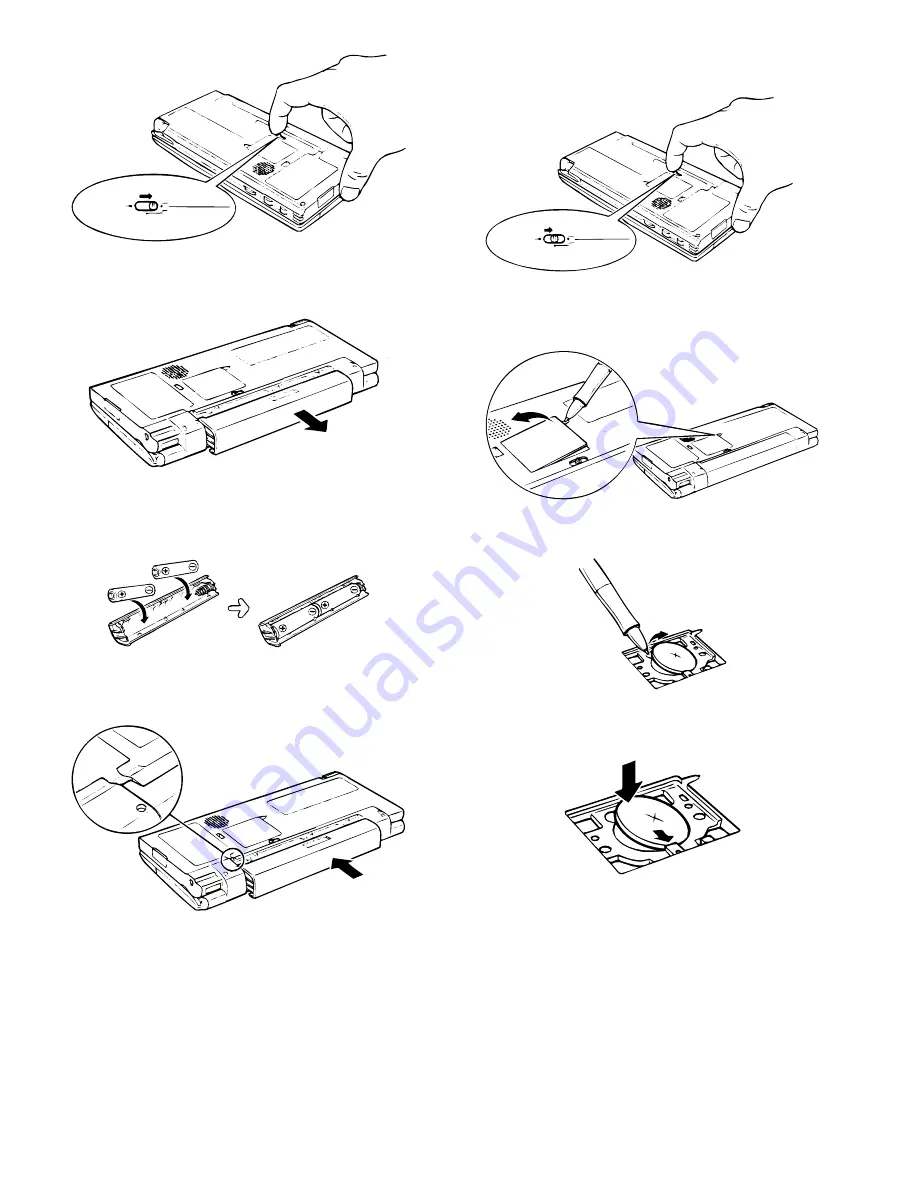

2. Slide the battery replacement switch to the REPLACE MAIN BAT-

TERIES position.

3. Pull out the battery holder and remove the old batteries. Discard

them properly.

4. Insert two new AA alkaline batteries into the battery holder, noting

the directions indicated by the plus (+) and minus (–) signs inside

the holder.

5. Reattach the battery holder to the unit, noting the position of the

projecting part on the battery holder.

6. Slide the battery replacement switch back to the NORMAL OP-

ERATION position.

If this proves difficult, check to make sure the main battery holder

is completely inserted.

7. After battery replacement, turn on the unit and make sure no

warning message appears.

Replacing the backup battery

1. Turn off the unit.

2. Slide the battery replacement switch to the REPLACE BACKUP

BATTERY position.

3. Use a ballpoint pen to open the backup battery cover. Do not use

the stylus.

4. Remove the old backup battery with a ballpoint pen.

5. Insert a new CR-2032 lithium battery with the plus (+) sign facing

up.

6. Put the backup battery cover back in place and slide the battery

replacement switch to the NORMAL OPERATION position.

7. After battery replacement, turn on the unit and make sure no

warning message appears.

NORMAL OPERATION

REPLACE MAIN BATTRIES

REPLACE BACKUP BATTERY

NORMAL OPERATION

REPLACE MAIN BATTRIES

REPLACE BACKUP BATTERY

– 36 –