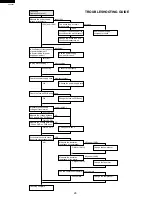

30

AF-06CSL

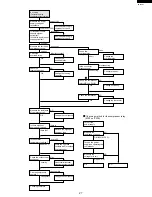

Excessive vibration

or Abnormal noise

At fan only mode,

Excessive vibration

or Abnormal noise

Check the air filter

NO

OK

NG

OK

OK

OK

OK

OK

OK

OK

too big

NG

touching

NG

OK

NG

YES

not dirty

dirty

Clean the air filter.

Check the fan motor

connector.

deform or broken

loosened

loosen

Measure the resistance

of fan motor coil.

Change the fan motor.

Connect properly.

Change the fan

Tighten up.

Check rotating

direction of centrifugal

fan.(to clockwise)

Is the fan deformed or

broken.

Is loosened screw

and nut fixing fan ?

Checking complete

Tighten up

Repair with adjusting

shape of pipes.

Repair mounting or

change compressor

cushion.

Change compressor.

Is each screws

loosened ?

Is pipe touching to

another parts.

Check mounting of

compressor.

Check compressor

noise and vibration.

Checking complete