33

13VT-L200

3. Tape run adjustment

1

Connect the oscilloscope to PB CHROMA envelope

output test point, set oscilloscope sync to EXT,

trigger-input the PB CHROMA signal (head switch-

ing pulse).

2

Rough adjustment of X value

Tentatively fix A/C head arm screws

1

and

2

by

the method described in Page 30 "Replacement 3".

After shortcircuiting TP7701 and TP7702, plug in the

powercord, then turn on the power. And playback the

alignment tape (VRONBZGS). As a result the auto-

tracking is automatically cancelled, so that the X

value adjustment mode is set.

Move the A/C head with the X value adjustment gear

driver (JiGDRiVER-6) by the method shown in Figure

1-33, and adjust the A/C head so as to get the

maximum envelope waveform. (Note: When the A/C

head is adjusted, adjust so that the maximum en-

velop waveform is obtained nearest the position of

initial setting made in Page 30.)

3

Next, change the alignment tape to VROEFZCS to

play back. Press the tracking button (+), (–) and

change the envelope waveform from max to min and

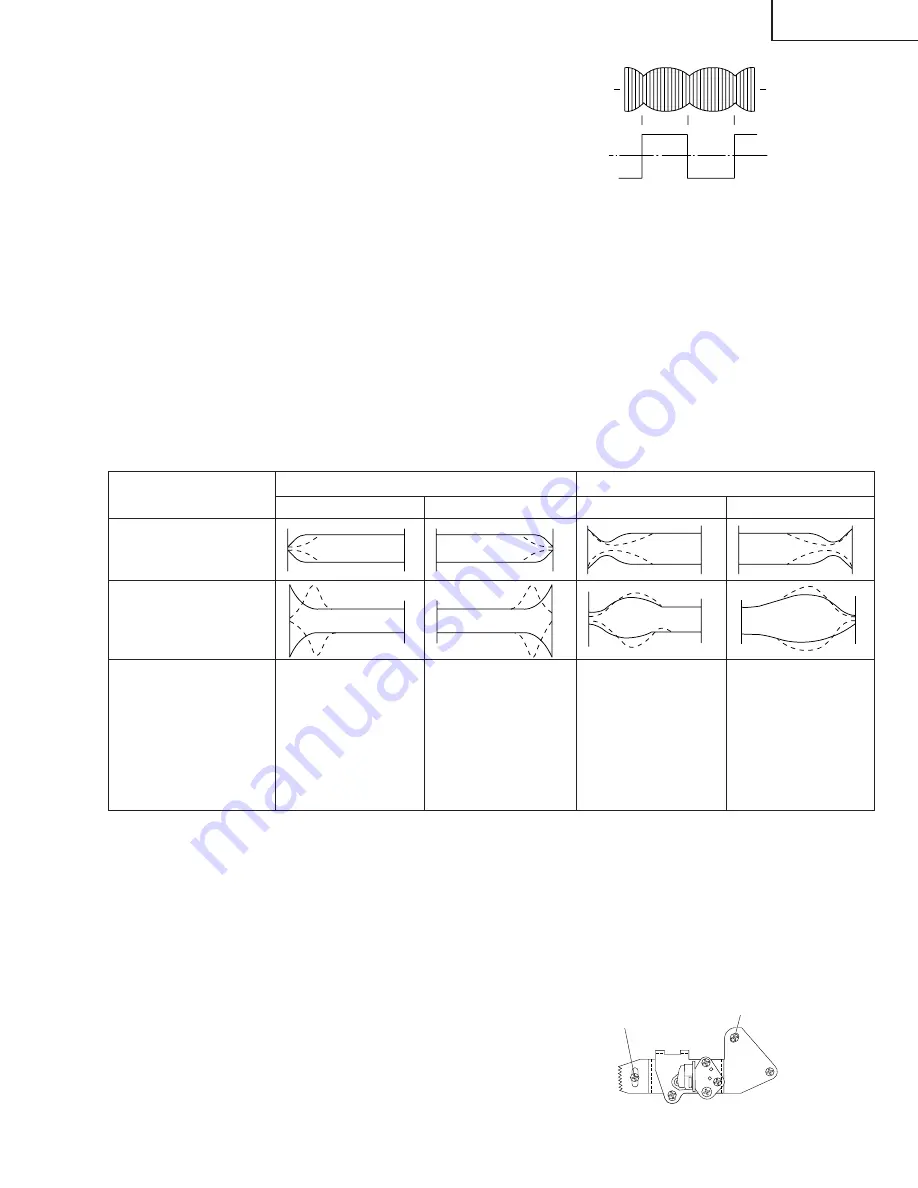

When the tape is above the helical lead.

When the tape is below the helicallead.

Take-up side

Supply side

Take-up side

Adjustment

Supply side

Supply side guide roller

rotated in clockwise

direction (lowers guide

roller) to flatten

envelope.

Take-up side guide roller

rotated in clockwise

direction (lowers guide

roller) to flatten

envelope.

Supply side guide roller

rotated in counterclock-

wise direction (raises

guide roller) to make the

tape float above the helical

lead. The supply

side guide roller is then

rotated in the clockwise

direction to flatten the

envelope.

Take-up side guide roller

rotated in counterclock-

wise direction (raises

guide roller) to make the

tape float above the

helical lead. The take-up

side guide roller is then

rotated in the clockwise

direction to flatten the

envelope.

Figure 1-35.

4. A/C head X value adjustment

1

Tentatively fix A/C head arm screws

1

and

2

by

the method described in Page 30 "Replacement 3".

2

After shortcircuiting TP7701 and TP7702, plug in the

powercord, then turn on the power. And playback the

alignment tape (VROEFZCS). As a result the auto-

tracking is automatically cancelled, so that the X

value adjustment mode is set.

3

Move the A/C head with the X value adjustment gear

driver by the method shown in Figure 1-33, and

adjust the A/C head so as to get the maximum

envelope waveform. (Note: At this time adjust so as

to get the maximum envelope waveform nearest the

A/C head position which has been set in case of X

value rough adjustment as stated in Page 33, 3-

2

.)

4

Tighten finally the screws

1

and

2

. Be sure to

tighten at first the screw

1

and then the screw

2

.

PB CHROMA

Envelope

Figure 1-34.

Final tightening torque is 0.6N·m (If the screw

2

is

tightened first, the X value may deviate.)

5

Adjust the playback switching point (Refer to the

electric adjustment method.)

6

Playback the self-picture-recorded tape, and check

the flatness of envelope waveform and sound.

Note:

When the A/C head X value adjustment is performed, be

sure to perform at first X value rough adjustment (refer to

Page 33, 3-

2

).

Figure 1-36.

from min to max. At this time adjust the height of

supply and take-up side guide roller with the adjust-

ment driver (JiGDRiVERH-4) so that the envelope

waveform changes nearly parallel.

4

If the tape is lifted or sunk from the helical lead

surface, the PB CHROMA envelope waveform ap-

pears as shown in Figure 1-35.

5

Press the tracking button (+), (–) and make sure that

the envelope waveform changes nearly parallel.

6

Finally check tape crease near the reverse guide. If

tape crease is found, remove it as stated in Page 31

"HEIGHT ADJUSTMENT OF REVERSE GUIDE"

item 3.

1

2

Head switching pulse

CH-1

CH-2

Summary of Contents for 13VT-CL10

Page 7: ...7 13VT L200 Description Of Controls FRONT LOCATION OF USER S CONTROL REAR ...

Page 56: ...56 13VT L200 8 7 10 9 6 5 4 3 2 1 A B C D E F G H CHASSIS LAYOUT PWB B PWB D PWB C ...

Page 57: ...57 13VT L200 17 16 19 18 15 14 13 12 11 10 PWB A ...

Page 58: ...58 13VT L200 8 7 10 9 6 5 4 3 2 1 A B C D E F G H BLOCK DIAGRAM OF TV SECTION ...

Page 59: ...59 13VT L200 17 16 19 18 15 14 13 12 11 10 ...

Page 61: ...61 13VT L200 17 16 19 18 15 14 13 12 11 10 ...

Page 63: ...63 13VT L200 17 16 19 18 15 14 13 12 11 10 ...

Page 67: ...67 13VT L200 17 16 19 18 15 14 13 12 11 10 ...

Page 69: ...69 13VT L200 17 16 19 18 15 14 13 12 11 10 ...

Page 70: ...70 13VT L200 8 7 10 9 6 5 4 3 2 1 A B C D E F G H OVERALL SCHEMATIC DIAGRAM ...

Page 71: ...71 13VT L200 17 16 19 18 15 14 13 12 11 10 ...

Page 74: ...74 13VT L200 8 7 10 9 6 5 4 3 2 1 A B C D E F G H SCHEMATIC DIAGRAM MAIN 1 Unit TV Section ...

Page 75: ...75 13VT L200 17 16 19 18 15 14 13 12 11 10 ...

Page 76: ...76 13VT L200 8 7 10 9 6 5 4 3 2 1 A B C D E F G H SCHEMATIC DIAGRAM MAIN 2 Unit TV Section ...

Page 77: ...77 13VT L200 17 16 19 18 15 14 13 12 11 10 ...

Page 78: ...78 13VT L200 8 7 10 9 6 5 4 3 2 1 A B C D E F G H SCHEMATIC DIAGRAM POWER Unit TV Section ...

Page 79: ...79 13VT L200 17 16 19 18 15 14 13 12 11 10 ...

Page 80: ...80 13VT L200 8 7 10 9 6 5 4 3 2 1 A B C D E F G H SCHEMATIC DIAGRAM MAIN Unit VCR 1 Section ...

Page 81: ...81 13VT L200 17 16 19 18 15 14 13 12 11 10 ...

Page 82: ...82 13VT L200 8 7 10 9 6 5 4 3 2 1 A B C D E F G H SCHEMATIC DIAGRAM MAIN Unit VCR 2 Section ...