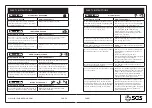

PARTS LIST

PART

DESCRIPTION

QTY

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

Main housing

O-ring

O-ring

Valve stem

O-ring

Trigger stand

O-ring

F/R valve

Spring

Trigger

Hex screw

Trigger bolt

Muffler

Spacer

Air inlet

Gasket

Bearing

Rear plate

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

PART

DESCRIPTION

QTY

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

Rotor

Rotor blade

Cylinder

Fixing shaft

Front plate

Cushion

Gear

Bolt

Rotating axle

Gear ring

Bearing

Fixing ring

Cushion

Chuck

Screw

Chuck key

Handle grip

1

5

1

1

1

1

3

3

1

1

2

1

1

1

1

1

1

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

EC Declaration of Conformity

This is an important document and should be retained

MANUFACTURER’S NAME:

TYPE OF EQUIPMENT:

I, the undersigned, hereby declare that the equipment speci-

fied above conforms to the above European Communities

Directive(s) and Standard(s).

PLACE:

DATE:

(Signature)

Robert Wyatt

Company Secretary

Derby, UK

24th JUNE 2017

SGS Engineering (UK) Ltd

SGS Engineering (UK) Ltd

West Side Park

Raynesway

Derby, DE21 7AZ

Air Drill

SAT203

2006/42/EC

Machinery Directive

EN1494:2000 + A1:2008

Mobile or movable jacks and

associated

lifting

equipment