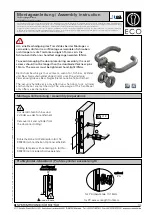

A. Make sure the lock bolt doesn’t bind against the safe’s boltwork. The top photo shows binding of the edge of

the cutout in the safe’s blocking bar, even though the boltwork is fully thrown to the locked position. In the

bottom photo, the binding has been relieved by removing a small amount of material from the side of the

blocking bar cutout. It is important that there is clearance on all sides of the lock’s bolt when the boltwork is

in the fully locked position. Binding will impair the lock’s performance. Any necessary modifications should

be made to the boltwork, not the lock.

B. If your safe incorporates a relock device, you will need to attach the plate that normally holds it in check to

the lock body. This is usually done at the lock’s cover screw locations. Remove the cover screws. DO NOT

REMOVE THE LOCK COVER, as this will void the product warranty. Typically, the cover screws will be

replaced with slightly longer 8-32 machine screws. Your replacement screws must engage the threaded holes

in the lock body by at least four threads. Relock device designs vary from safe to safe. You must make sure

the replacement cover screws hold the lock cover firmly against the lock body, and that the relock device

plate holds the device securely in check. Otherwise, there is risk of a lockout. After the plate is installed, once

again check to make sure wires and cables are secured so that they will not come into contact with moving

boltwork or anything else that can damage them.

Lock installation Considerations

Incorrrect

Corrrect

3