WARNING

: The power cords of the HVE3000 should be

plugged into separate GFCI-protected 115 volt outlets

rated for at least 15

amps. Always plug the cord firmly

into the base of the unit first and secure the cord into the

cord clip.

NOTICE:

Connect to two separate 15A circuits ONLY. A

bright green light indicates correct connections. No light

will show when using only one cord.

3) Connect pumpout hose to pump outlet and turn

pump switch ON.

For maximum pumpout performance,

we recommend using the unit with a 1½ in outlet hose.

See “Maximizing pumpout performance” below.

4) Attach vacuum hose to truckmount via vacuum

outlet.

5) Turn on vacuum blower(s) to LOW, MED or HIGH.

The machine can operate with either one or both

blowers running. For maximum vacuum pressure, turn

on both Blower 1 and Blower 2.

TRUCKMOUNT BOOSTER OPERATION TIP

Place the HVE3000 as close as possible to the end of

the hose run nearest the wand or other extraction tool.

This position will maximize the vacuum boost provided

by the unit.

Maximizing pumpout performance

The sump pump outlet of HVE3000 is equipped with a

1½ in. barbed hose fitting for use with a 1½ in. drain

hose (hose purchased separately). Because the internal

pumpout system is plumbed with 1½ in. lines, use of a

large-diameter drain hose will help to ensure maximum

pumpout performance.

The HVE3000 may also be used with a standard garden

hose. Simply replace the 1½ in. fitting with the ¾ in.

reducer fitting supplied with your unit and attach the

garden hose.

NOTICE:

Before turning the pump on, attach a drain

hose and place the end into a sink, toilet, or other

suitable drain. Operating the pump without a drain hose

in place may cause injury.

NOTICE:

Avoid contact with water draining from the

pump outlet. Water is pressurized and may exit the unit

with force. Water may contain chemicals or

contaminants that can be a health hazard upon contact.

Airflow shut-off

The HVE3000 will automatically shut off airflow to the

blowers when the recovery tank is full. This prevents

water and debris from entering the motors. When the

recovery tank becomes excessively dirty, or if there is

too much foam in the tank, the float may not function

properly. When the blowers emit a high-pitched whine

and there is no vacuum generated, it most likely means

that the ball float has engaged and that the tank is full

and needs to be emptied, or that excessive foam is

present. When this occurs, check the tank and empty it

if necessary, and use a defoamer any time foam is

present.

MAINTENANCE

WARNING! ELECTRIC SHOCK HAZARD.

Unplug the

unit before performing any maintenance.

Before each use

Inspect the electrical cord for damage.

Look for

fraying, cuts, etc. Do not use the unit if you find any

damage. Call 800-932-3030 to locate the nearest service

center.

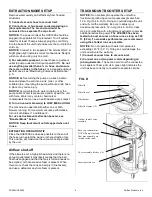

Check the filter basket

(Fig. D).

Remove debris and

rinse clean if needed.

Check the HEPA filter

(Fig. D).

Replace if visibly dirty.

To access the filter, remove the filter cover plate

thumbscrews and lift off the plate. Replacement filters

are sold in packs of four. Ask for Dri-Eaz part no. F503

or Sapphire part no. 20-045.

Check the sump pump float valve

(Fig. D).

Remove

any clogs or obstructions to the float mechanism.

Check the manual drain hose

for clogs or kinks.

Check all hose fittings.

Look for cracks, debris, and

damaged threads or seals.

Check ball float valve.

Ensure cover screen is clean.

After each use

Clean filter basket and top cover.

Release cover

clamps, remove the cover, and lift out basket. Rinse

basket, basket basin, and cover with water to clean.

(Clean also as needed during use.)

Clean recovery tank, float valve, and airflow shutoff

valve.

1. Release four cover assembly latches and lift off cover

assembly (see Fig. D). With gravity drain hose directed

into a suitable drain, remove any accumulated debris

and wash recovery tank interior with an all-purpose

detergent. Rinse interior with fresh water. Allow the unit

to drain completely through the gravity drain hose.

2. Slide airflow shutoff ball valve assembly downward off

of the vacuum standpipe (Fig. D; see also “Remove float

ball assembly,” p. 7). Rinse valve assembly clean. Make

sure the float ball moves freely inside the cage and is

free of any debris. Replace ball valve assembly.

3. Wipe off pump, float, float arm assembly and tank

interior with a damp cloth. Allow tank interior and cover

assembly to dry completely before replacing the cover

assembly.

To maintain appearance

, wipe interior and exterior

surfaces with a damp cloth. For deep cleaning and to

add a protective shine to the exterior, use Dri-Eaz

SP004 HVE3000

5

Dri-Eaz Products, Inc.