INTRODUCTION

Welcome to the Serpent owners network! By buying

the Cobra GT, you have become part of the fast growing

baseof Serpent drivers around the world, active in

most classes of rc car racing. Serpent racers share

their knowledge and experiences on the tracks and on

the internet, so join in!

The Serpent Cobra GT is a high-end racing car, for

competition purposes. The Serpent Cobra GT offers

state of the art specifications and leads the way in

1/8 scale gas on-road chassis design, using all the

knowledge our designers have gathered from racing

on-road cars for over 35 years, into this design too.

Continuously pushing the performance envelope.

Designed, tested and raced by Billy Easton and Michael

Salven, World Champions.

All information about the Serpent Cobra GT is accessible

from the Serpent Cobra GT product page which can be

found on Serpent.com and can be accessed by simply

typing serpent.com/600046 into your web browsers

address bar. From the Serpent Cobra GT product page

you will find the very latest information about your

car: reports by team drivers and other experts, tips

and tricks, setups, image gallery and downloadable

files including the latest version of the instruction

manual is available as downloadable PDF-files.

Enjoy assembly, preperations and racing !

Team Serpent

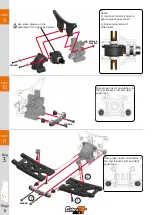

INSTRUCTIONS

Serpent’s long tradition of excellence extends to the

instruction manuals, and this instruction manual

is no exception. The easy-to-follow layout is richly

illustrated with 3D-rendered full-color images to make

your building experience quick and easy. Following the

instructions will result in a well-built, high-performance

race-car that will soon be able to unleash its full

potential at the racetrack.

INSTRUCTIONS, hOw TO USe

The kit includes bags, with bagnumbers, which

refer to the same step in the manual. Open only the

indicated bag(s) per step and finish that part of the

assembly. Remaining parts will be needed lateron in

the assembly process.

SeTUP

In certain assembly steps you need to make basic

adjustments, which will give you a good initial setup

for your Serpent Cobra GT. Fine-tuning the initial setup

is an essential part of building a high-performance

racecar like your Serpent Cobra GT.

eXPLODeD VIewS AND PARTS LIST

The exploded views and parts lists for the Serpent

Cobra GT are presented in the Reference Guide section

in the back of this manual. The exploded views show

all the parts of a particular assembly step along with

the Serpent part number. The parts lists indicate the

part number andname of each part for easy reference

when ordering.

CUSTOmeR SeRVICe

Serpent has made a strong effort to make this manual

as complete and clear as possible. Additional info may

be published in our website: www.serpent.com or you

may ask your dealer or the Serpent distributor for

advice, or email Serpent direct: [email protected]

The Serpent Facebook, Twitter and Youtube pages give

additional means of support and communications.

SAfeTy

Read and take note of the ‘Read this First section’

before proceeding to assemble the car-kit. This car-kit

is intended for persons aged 16 or older.

Read this first!

- This is a highly technical hobby product, intended to be used in a safe

racing environment. This car is capable of speeds in excess of 80 km/h

or 50mph. Please follow these guidelines when building and operating

this model.

- Parental guidance is required when the builder/user of this car is

under 16.

- Follow the building instructions. If in doubt, contact your dealer or

importer.

- Be sure to use the proper tools when assembling the car. Always

exercise caution when using electric tools, knives and other sharp

objects.

- Be careful when using liquids like lubrication oil, fuel or glue. Do not

swallow.

- Follow the manufacturer’s instruction in case you experience irritation

after using the product.

- Be careful when operating the car. Stay away from any rotating parts

such as wheels, gears and transmission. Stay away from motor, engine

and exhaust pipe system or speedo during and immediately after use,

as these parts may be very hot. We advise to use protective hand

cloves.

- Only operate this car in a safe environment, like a special racing track

or a closed parking lot. Avoid using this car on public roads, crowded

places or near infants.

- Before operating this car, always check the mechanical status of the

car. Also check that the transmitter and receiver frequencies correspond

and are not used by any other racer at the same time. Check that the

batteries of the transmitter and receiver- are fully charged.

- After use, always check all the mechanics of the car. We advise to

clean the car immediately after use, and inspect the parts for wear or

fractures.

Replace when necessary. Do not use water, methanol, thinner or other

solvents to clean the car.

- Empty the fuel tank (depending on model) if needed and disconnect

the

receiver battery.

- Store the car in a dry and heated place to avoid corrosion of metal

parts.

- Avoid using this car in wet conditions as the water will cause corrosion

on

the metal parts and bearings and these parts will cease to function

properly.

If driven in the wet, ensure that all the electric equipment is

waterproofed

and after use, that all moving parts are dried immediately.

CONTENTS

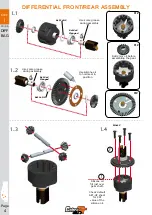

DIffeReNTIAL ASSemBLy

4

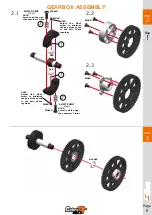

GeARBOX ASSemBLy

5

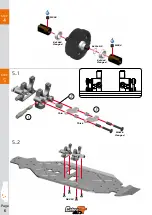

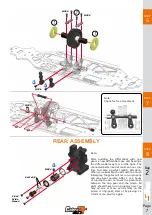

ReAR ASSemBLy 7

fRONT ASSemBLy

12

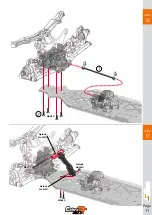

STeeRING ASSemBLy

16

CLUTCh ASSemBLy 19

RADIO ASSemBLy 20

ShOCKS ASSemBLy

24

fINAL

ASSemBLy

28

Ref

GUIDe

31

Summary of Contents for Cobra GT 3.0

Page 1: ...INSTRUCTION MANUAL REFERENCE GUIDE...

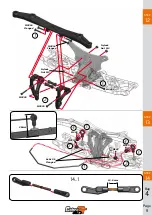

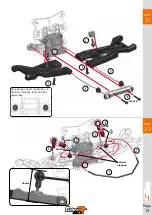

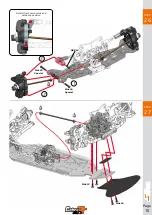

Page 11: ...Page 11 STEP 16 STEP 17 M4X12 M3x12 M3x22 1 2 Nylock Nut M3 Nylock Nut M3 Nylock Nut M3...

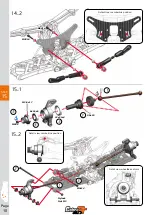

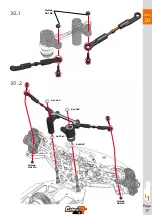

Page 16: ...Page 16 STEP 28 STEP 29 M4X10 M4X10 M4X10 21 mm 29 1 29 2 4mm 1 2 Bag 7 STEERING ASSEMBLY...

Page 21: ...Page 21 STEP 37 STEP 38 M2x10 5x8x2 5 5x8x2 5 M3x20 1...

Page 22: ...Page 22 STEP 39 STEP 40 NOT INCLUDED NOT INCLUDED M3x8 M3x8 M3x8 M3x3 M3x3 M3x3 1 2 3...

Page 23: ...Page 23 STEP 41 STEP 42 M4x12 M4x12 M4x12 M4x12 M3x3...

Page 30: ...Page 30 STEP 54 STEP 53 2x14 M2x10 M2x10 2x14 2 2 2 3 3 1 1 WHEELS AND TYRES NOT INCLUDED...

Page 41: ...www serpent com info serpent com Cobra GT 3 0 manual v1...