1

3

5

9

4

2

14

11

10

12

13

15

16

11

12

To

body

17

Full Open Capacity

Capacity of the model 121 in the wide-open position can be calculated

using the following formula and K factors:

1.

Q = K P

0

(P

1

- P

0

)

2.

Q = KP

1

2

Q = maximum capacity of the regulator

(in SCFH of 0.6 specific gravity natural gas)

K = the regulator constant

“K” factor;

P

0

=

absolute

inlet pressure (psia)

P

1

=

absolute

outlet pressure (psia)

Use formula 1 when P

1

is less than 1.894

P

0

Use formula 2 when P

1

is greater than 1.894

P

0

3.

K Factors =

1" Pipe Size (outlet)

K= 1400

1-1/4" Pipe Size (outlet)

K = 1750

1-1/2" Pipe Size

K = 2750

2" Pipe Size

K = 4750

2-1/2" Pipe Size

K = 5250

3" Pipe Size

K = 11000

4" Pipe Size

K = 18000

Remember, at the above full open capacities the droop is significantly

greater than specified in the capacity tables. When checking 121

regulator capacity to provide adequate relief valve capacity, use the

above calculated full open capacity.

Installation and Maintenance

Model 121 Regulators – Variations

Maximum Emergency Pressures

The Maximum inlet pressures model 121 bodies may be subjected

to under abnormal conditions without causing internal damage

are as follows:

1" through 2-1/2" pipe sizes

70 psi

3" pipe size

50 psi

4" pipe size

25 psi

The maximum pressures the diaphragms in model 121 regulators may

be subjected to under abnormal conditions without causing internal

damage are as follows:

Model 121-8

set-point plus 5 psi

Model 121-8HP

set-point plus 10 psi

Model 121-12

set-point plus 5 psi

Model 121-16

set-point plus 2 psi

Set-point is defined as the outlet pressure a regulator is adjusted

to deliver.

If any of the above limits are exceeded the regulator must be taken

out of service and inspected. Damaged or otherwise unsatisfactory

parts must be repaired or replaced before returning the regulator

to service.

The maximum pressures that can be safely contained by model 121

diaphragm cases are as follows:

Model 121-8

25 psi

Model 121-8HP

25 psi

Model 121-12

20 psi

Model 121-16

10 psi

Safely contained means no leakage as well as no bursting.

Before using any of the above data, make sure this entire section

is clearly understood.

22

Model 121 Regulators

121-PL (Pressure Loaded)

The 121-PL is a pressure loaded, Pilot Operated Regulator. The

pressure loading of the diaphragm minimizes droop caused by spring

and diaphragm effect, thus providing more accurate control. The

outlet set pressure is controlled by adjusting the pilot regulator of the

121-PL. The main regulator spring is

NOT t

o be adjusted. The two

available pressure ranges are 3-1/2" w.c. to 20 psig and 3-1/2" w.c.

to 35 psig, governed by two available pilot regulators.

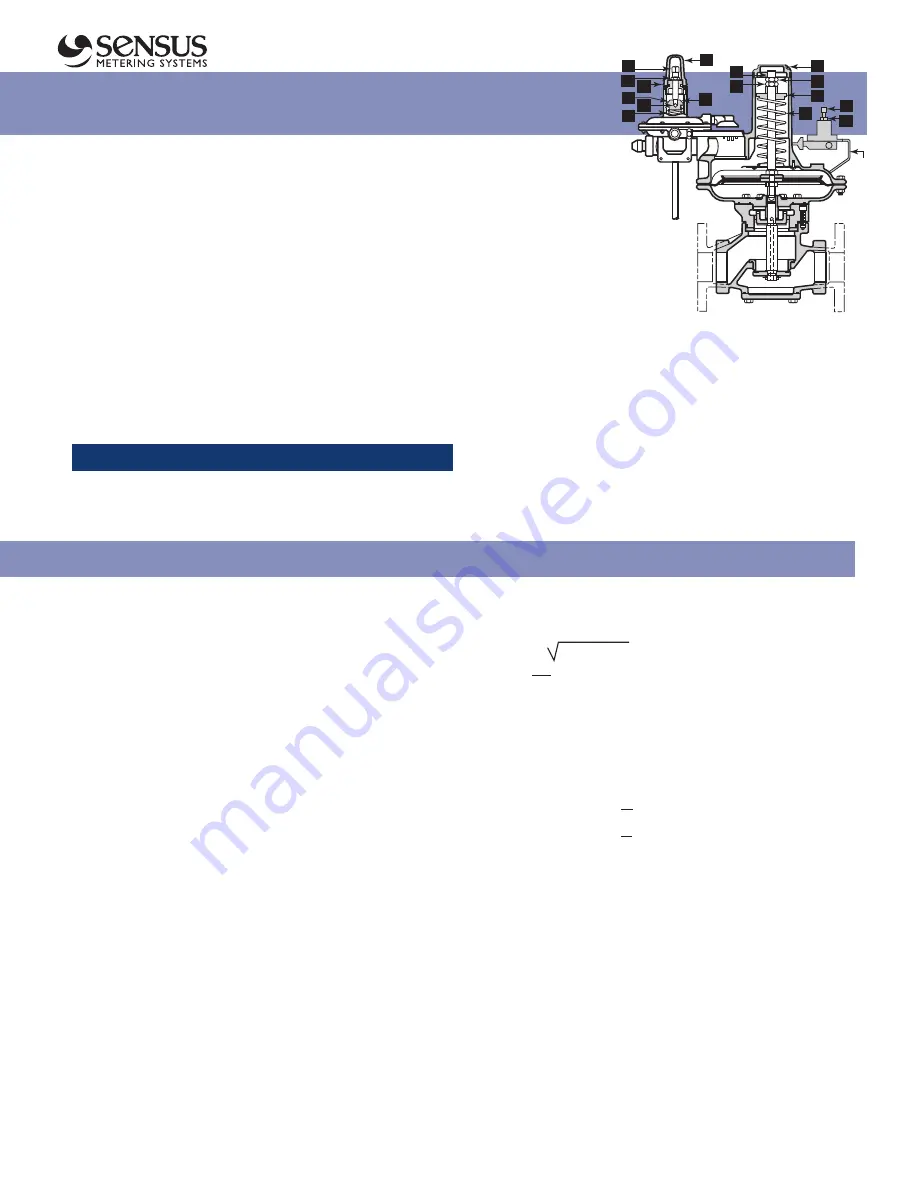

Set-Point Adjustment

The 121-PL is factory adjusted as specified on the order.

To change set point:

1.

Loosen lock nut

12

on pilot regulator top

2.

Rotate set-point adjustment 11 of pilot regulator clockwise to

increase or counter clockwise to decrease the outlet pressure.

3.

When the desired set-point is achieved, retighten lock-nut

12

.

CAUTION

Do not remove main cover cap 1. The upper case is sealed

and pressurized. The main spring is not to be adjusted to control

outlet pressure.

To Service 121-PL

1.

Take regulator out of service

per the following section

“Shut Down”.

2.

Remove cover cap

1

. Measure

depth from top of cover to ferrule

5

for reassembly.

3.

Hold stem

2

from turning using

screwdriver on end of stem.

4.

Unlock nut

3

from nut

4

and remove nut

3

.

5.

Slowly remove nut

4

maintaining pressure on the spring

ferrule

5

to prevent ejection of the spring from the upper case.

CAUTION:

Do not allow stem

2

to unscrew during

removal of nut

4

.

6.

Remove spring

9

.

7.

At pilot, disconnect control line which connects to

downstream piping.

8.

Disconnect pilot supply line between body and pilot regulator.

9.

Follow procedures for standard 121 regulators by size.