USER MANUAL

EvaluationTool

STIM202 Evaluation Kit

DOK333 rev.06 17/22 Dec 2017

7.3

Normal mode panel descriptions

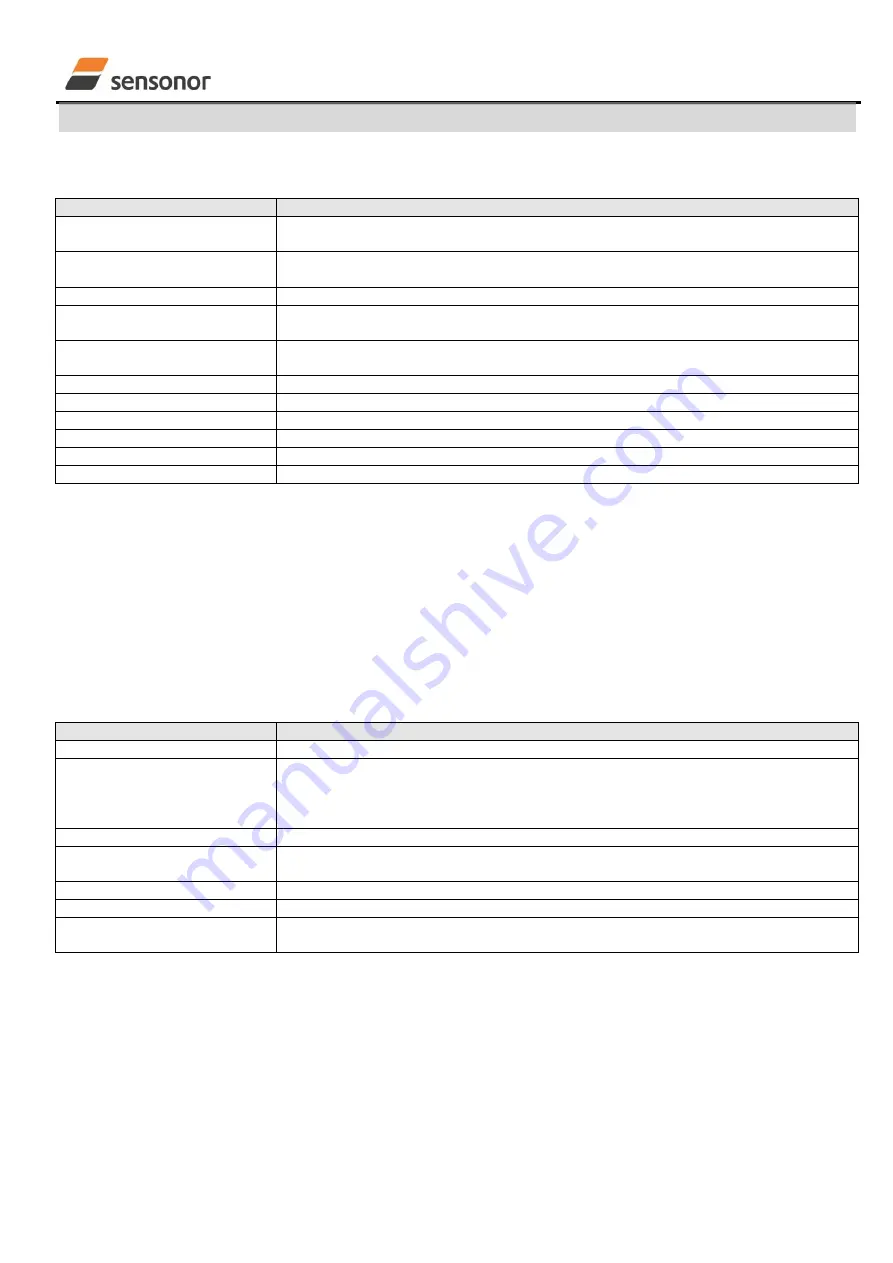

Table 1: Normal mode panel descriptions

Panel unit

Functionality and description

Connect to HW

To connect to interface hardware. Opens PC COM port according to selections in

active parameter file

LED(s)

Indicator for hardware connection. A GREEN light indicates the corresponding COM

port is opened. If two units are connected a second LED will appear

Disconnect from HW

To Disconnect from interface hardware. Closes the corresponding COM port

Apply voltage switch (On/Off)

To be switched manually (ON or OFF) by user when asked to. Controls certain

functions of the PC software

Device box

Should hold the correct gyro module (device) number according to active parameter

file. Choice depends on which gyro module and COM port the user wants to operate

Reset device button

Resets the gyro module

. Sends reset command (‘R’)

Request config DG button

Sends command (‘C’) to receive configuration datagram

Request identity DG button

Sends command (‘N’) to receive part number datagram

Request serial# DG button

Sends command (‘I’) to receive serial number datagram

Request ext. sts DG button

Sends command (‘E’) to receive extended error information datagram

Response window

Lists responses from the gyro module

7.4

Service mode panel descriptions

Service mode is used for gyro module configuration.

Service mode is entered by clicking on the Service mode tab next to the Normal mode tab. Panel units, functionalities

and descriptions are listed in Table 2. Exit from gyro module Service mode to Normal mode is done by pressing one of

the other panel tabs (Normal, Logging, Service or Parameter panel tab).

Note: Changes made for the gyro module in Service mode are only stored permanently in gyro module flash memory

when the

save command (‘s’) is issued.

Table 2: Service mode panel descriptions

Panel unit

Functionality and description

Available commands window

Shows a list of available commands. See product datasheet for details

Complete command window

Contains the complete command to send. It is auto-completed by usage of the

listings in the available commands window. Left click in the complete command

window shows a list of earlier sent commands. Right click enables manual command

entry

Send command button

Sends command to the gyro module

Active device indicator

Informs about the active gyro module (device). Corresponding COM port is according

to the active parameter file

Command response window

Shows the responses from the gyro module. See product datasheet for details

Erase button

Erases the content of the command response window

Save button

Saves the content of the command response window to a text file with a detailed

date and time tag