18

12.1 Plasma cutting process

The cutting action is obtained when the plasma arc, made very

hot and highly concentrated by the design of the torch, transfers

onto the conductive piece to be cut, closing the electrical circuit

with the generator. The material is first melted at a high tempe-

rature of the arc, and then removed by the high exit velocity of

the ionized gas from the nozzle.

The arc can have two different states: that of the transferred arc,

when the current passes through the piece to be cut, that of the

pilot arc or non-transferred arc, when this is sustained between

the electrode and the nozzle.

13.0 CUTTING SPECIFICATIONS

In plasma cutting, the thickness of the material to be cut, the

speed of cutting and the current supplied by the generator have

values which are related to each other; these depend on the type

and quality of the material, type of torch as well as the type and

condition of the electrode and nozzle, distance between nozzle

and piece, pressure and impurity of the compressed air, cut qua-

lity required, temperature of the piece to be cut, etc.

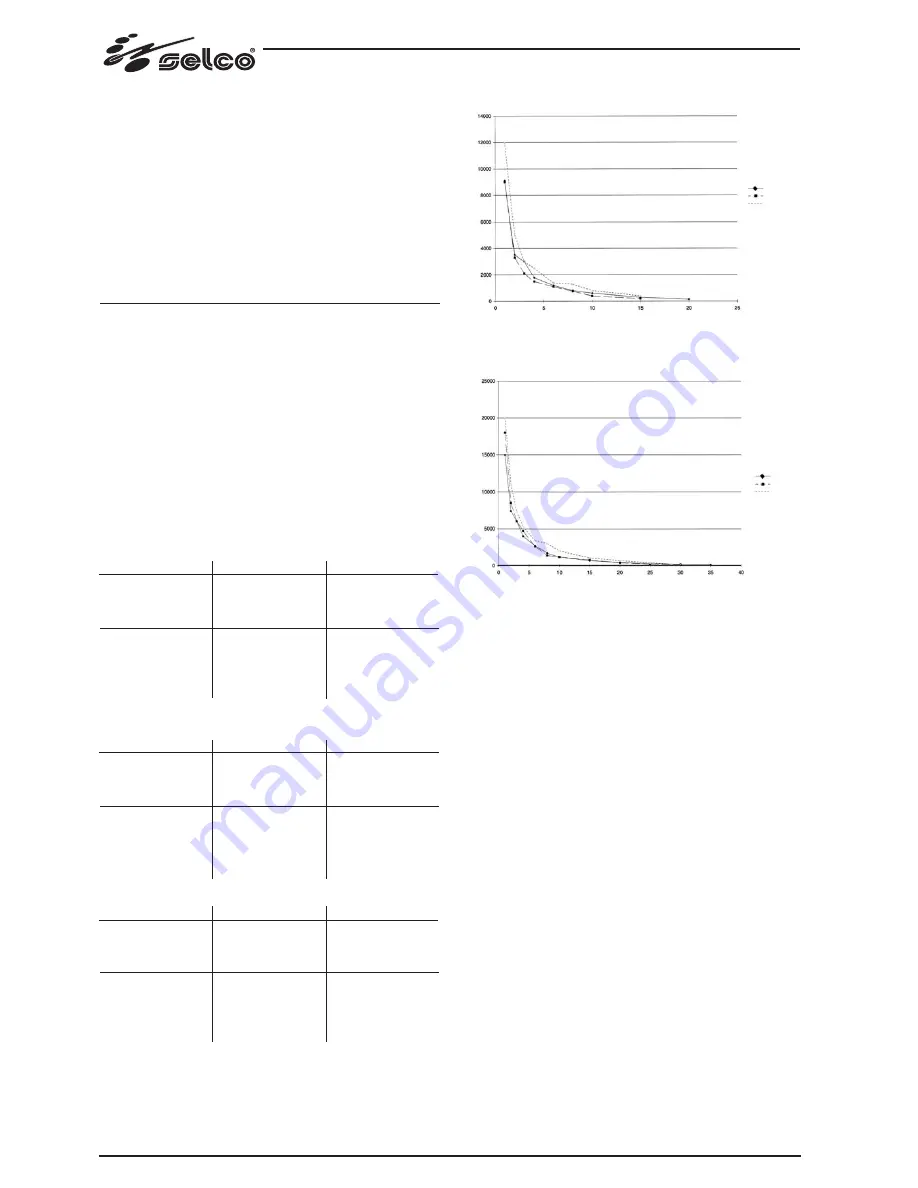

In the diagrams as in Fig.8, 9 we can see that the thickness to be

cut is inversely proportional to the cutting speed, and that both

these values can be increased with an increase in current.

The cutting tests have been performed in standard operating

conditions using a Trafimet torch at 90A.

MILD STEEL

STAINLESS STEEL

ALUMINIUM

* High quality cut

Fig. 8

Fig. 9

Thickness (mm)

3

6

10

15

3

6

10

20

30

Current (A)

50

50

50

50

80

80

80

80

80

Speed (mm/min)

3000

1200

600

300

6000

2700

1200

450

200

Thickness (mm)

3

6

10

15

3

6

10

20

25

Current (A)

50

50

50

50

80

80

80

80

80

Speed (mm/min)

2100

1000

400

200

6000

2600

1200

400

200

Thickness (mm)

3

6

10

15

3

6

10

20

25

Current (A)

50

50

50

50

80

80

80

80

80

Speed (mm/min)

3000

1400

800

400

7300

3400

2000

700

400

CUTTING SPEED WITH 50A

SPEED (mm/min)

SPEED (mm/min)

CUTTING SPEED WITH 80A

THICKNESS (mm)

MILD STEEL

STAINLESS STEEL

ALUMINIUM

MILD STEEL

STAINLESS STEEL

ALUMINIUM

THICKNESS (mm)