U.3.14

SEL-421 Relay

User’s Guide

Date Code 20090715

PC Software

Expression Builder

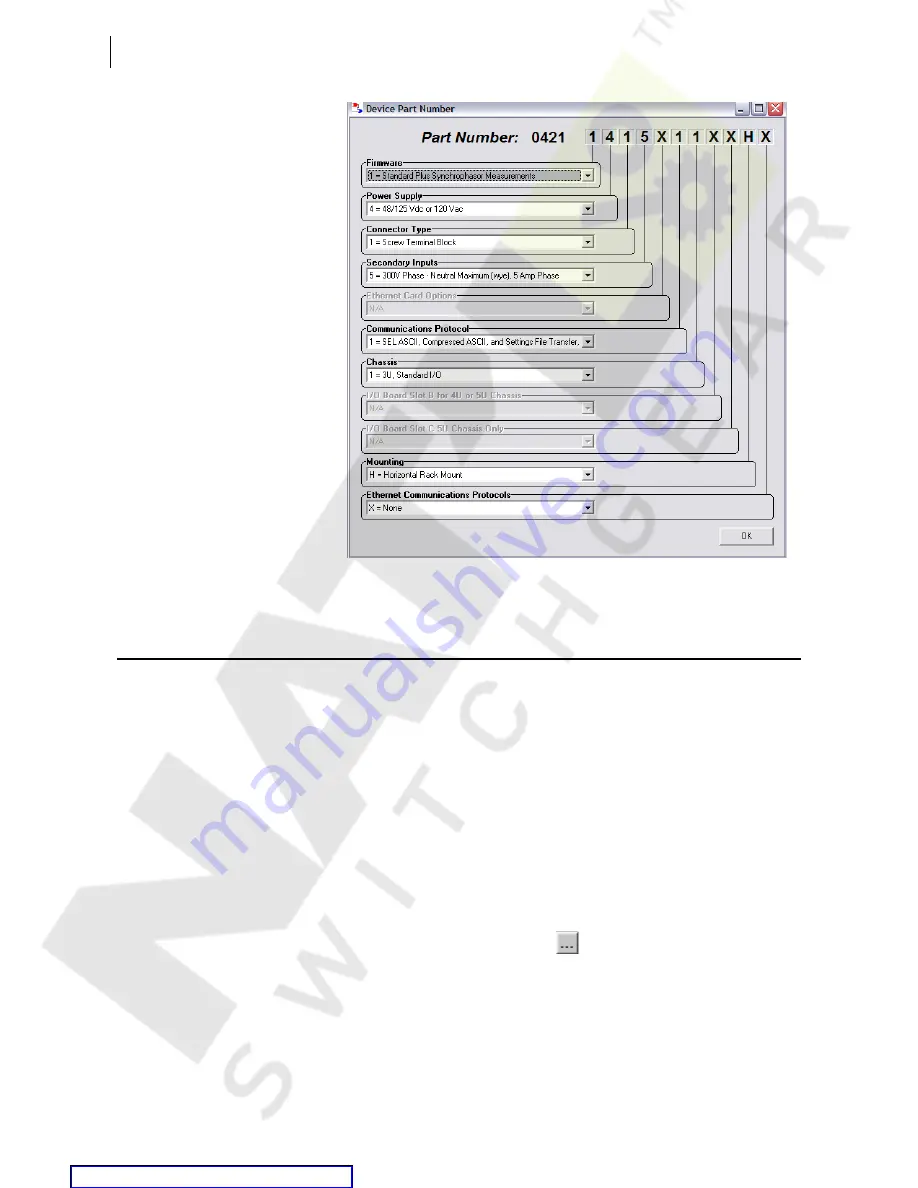

Figure 3.16

Setting the Relay Part Number in

AC

SEL

ERATOR

QuickSet

Expression Builder

SEL

OGIC

control equations are a powerful means for customizing relay

performance. Creating these equations can be difficult because of the large

number of relay elements (Relay Word bits) and analog quantities in the relay.

AC

SEL

ERATOR

QuickSet simplifies this process with the

Expression Builder

,

a rules-based editor for programming SEL

OGIC

control equations. The

Expression Builder

organizes relay elements, analog quantities, and

SEL

OGIC

control equation variables and focuses your equation decision-

making. The

Expression Builder

checks basic rules and flags mistakes in

SEL

OGIC

control equation settings.

Access the

Expression Builder

Settings dialog boxes (see

) in the

Relay Editor

window show the

following (ellipsis) button:

Click this button of a SEL

OGIC

equation to use the

Expression Builder

.

Summary of Contents for 421

Page 8: ...This page intentionally left blank Courtesy of NationalSwitchgear com ...

Page 22: ...This page intentionally left blank Courtesy of NationalSwitchgear com ...

Page 32: ...This page intentionally left blank Courtesy of NationalSwitchgear com ...

Page 42: ...This page intentionally left blank Courtesy of NationalSwitchgear com ...

Page 62: ...This page intentionally left blank Courtesy of NationalSwitchgear com ...

Page 116: ...This page intentionally left blank Courtesy of NationalSwitchgear com ...

Page 262: ...This page intentionally left blank Courtesy of NationalSwitchgear com ...

Page 308: ...This page intentionally left blank Courtesy of NationalSwitchgear com ...