SECO-LARM Mechanical Keypad Door Lock

SECO-LARM U.S.A., Inc.

5

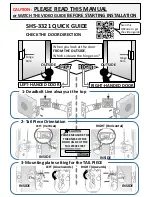

Prepare the Lock for Mounting:

Prepare the Door and Install the Latchbolt (Continued):

Changing the Interior Latchbolt Handedness (for left-handed doors)

NOTES:

A.

The interior lock assembly is set for right-handed doors from the factory. You should only

need to set the handedness of this unit if your door is left-handed.

B.

The exterior lock assembly is already set for left-handed doors from the factory.

Interior Lock Assembly

1.

Hold the interior handle assembly as it would be oriented for the handedness and swing of the

door to determine the correct handle orientation.

2.

Loosen the set screw (see Fig. 10) and rotate the handle to its correct horizontal position if

necessary (see Fig. 11). Tighten the set screw to maintain handle position.

3.

Check that the lever handle now turns in a clockwise direction and returns freely.

4.

Viewing the interior handle assembly from the back, note the blue handing screw's location—

right side for left-handed and left side for right-handed doors (see Fig. 11).

5.

If necessary, remove and change the location of the blue screw depending on the orientation

of the interior handle.

Positioning the Spindles

8.

Choose the correct spindle that best matches the door's thickness.

For doors less than 1

7

/

16

" (37mm), use the shorter spindle 2

15

/

16

"

(75mm). For doors 1

7

/

16

"~1

15

/

16

" (37~50mm) use the 3

3

/

8

" (85mm)

spindle. For thicker doors, use the 3

15

/

16

"(100mm) spindle.

9.

Position the spindle in the center, through the latch hub (Fig. 7)

according to the door's handing as shown in Figs. 8 and 9.

Fig. 7

Latch hub

Fig. 9

Spindle orientation for left-handed door

(viewed from outside)

Fig. 8

Spindle orientation for right-handed door

(viewed from outside)

Fig. 11

Left handed

Right handed

Blue handing

screw

Fig. 10

Set screw