Original language version

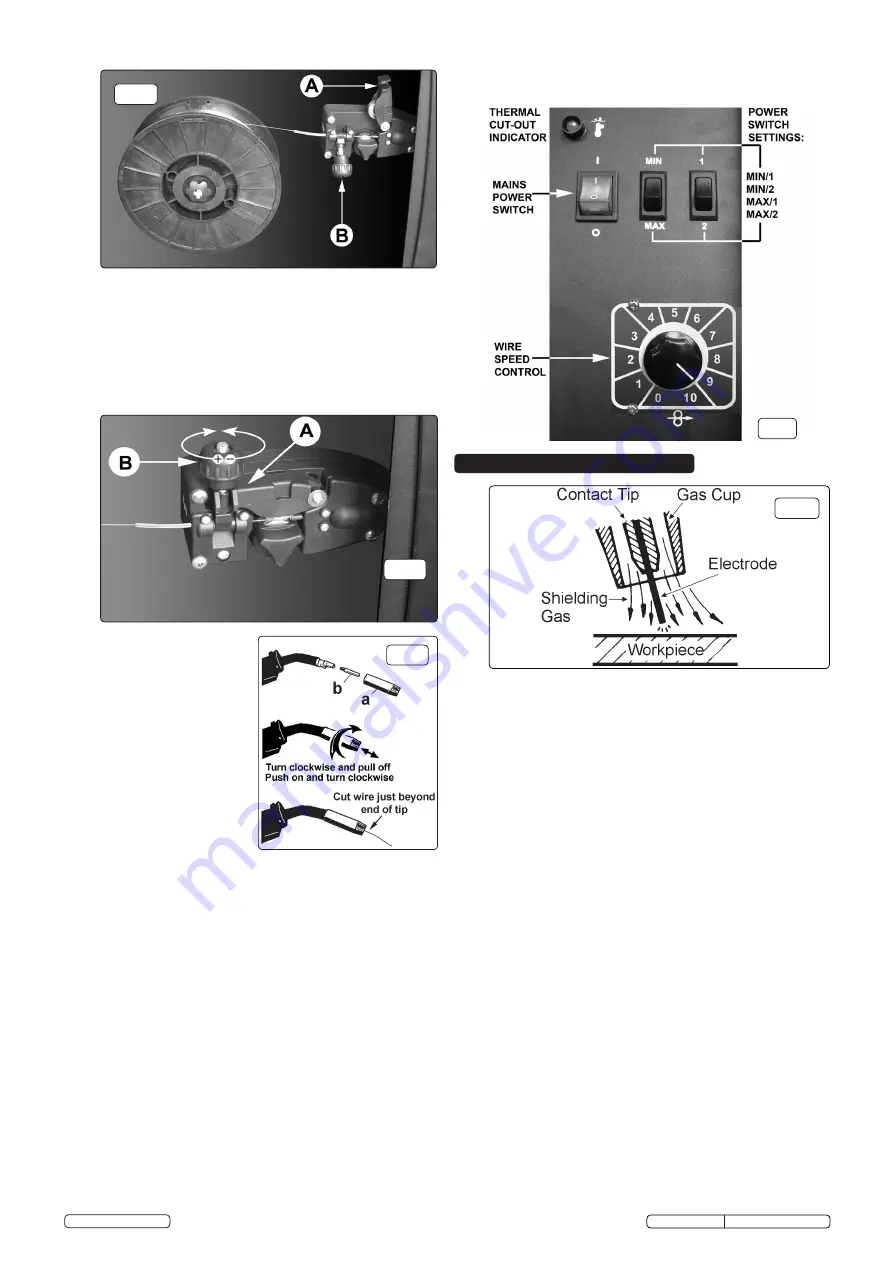

5.1. Mig/Mag welding.

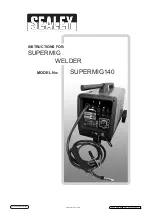

Welding wire is automatically fed through an insulated liner to the tip of

the torch. The torch consists of a switch, liner, gas hose, and control

cable. The switch activates the wire feed roller and the gas flow.

Releasing the switch stops wire feed and gas flow. The weld current is

transferred to the electrode (the wire) from the contact tip at the torch

end. The current to the electrode is set using the two switches on the

front of the control panel. Wire speed must be adjusted according to

current output using the rotary control below the power switches. The

higher the current the faster the wire speed. A gas cup fits over the

contact tip to direct gas flow towards the weld, (See fig.9) ensuring that

the arc welding process is shielded from oxidisation. The shielding gas

also assists heating of the weld. The torch is connected to the positive

side of a DC rectifier, and the negative clamp is attached to the

workpiece.

5.2. Preparation for welding:

IMPORTANT! BEFORE YOU COMMENCE,

MAKE SURE THE MACHINE IS SWITCHED OFF AT THE MAINS. IF

WELDING A VEHICLE, DISCONNECT THE BATTERY OR FIT AN

ELECTRONIC CIRCUIT PROTECTOR (AVAILABLE FROM YOUR

LOCAL SEALEY DEALER). ENSURE THAT YOU READ,

UNDERSTAND AND APPLY THE SAFETY INSTRUCTIONS IN

SECTION 1.

5.2.1. To ensure a complete circuit, the negative lead must be securely

attached to the workpiece close to the weld area. Best connection is

obtained by grinding the point of contact on the workpiece before

connecting the clamp.

5.2.2. The weld area must be free of paint, rust, grease, etc.

5.3. Gas types and their use.

Welding mild steel with CO² gas is appropriate for most welding tasks

where spatter and high build-up of weld do not pose a problem. To

achieve a spatter free and flat weld however, requires an Argon/CO²

mixture.

5.3.1. To weld aluminium use:

Argon Gas

0.8mm Contact Tip

0.8mm

Aluminium Wire (MIG/2/KAL08).

5.4. Thermal Protection.

Should the welder become overheated due to prolonged use beyond

the stated duty cycle, the thermal protection will cause the welder to cut

out and the amber light on the front panel will illuminate. Wait for fifteen

minutes for the welder to cool down at which time it will reconnect

automatically.

fig.9

fig.8

4.7 Control panel functions.

4.7.1 Refer to fig.8 below.

4.4.3. Referring to fig.5 turn the knob on the wire tension screw (B) anti-clock

wise and unlatch it from the pressure roller moulding. Swing the

pressure roller moulding (A) up and away from the drive roller.

4.4.4. Straighten 40-50mm of spool wire (do not allow wire to uncoil), and

gently push wire through the plastic guide and through the 6 or 8mm

feed roller groove and into the torch liner. Refer to section 7.5

on how to reverse the roller for either 6 or 8mm wire.

4.4.5. Referring to fig.6, move the pressure roller moulding (A) back

round onto the grooved drive wheel and swing the wire tension

screw (B) up to lock it in place. See 4.6 regarding wire tension.

fig.5

4.5. Feeding the wire through

to the torch.

(See fig.7)

Remove gas cup (a) and

contact tip (b) from end of

torch as follows:

a)

Take torch in left hand with

the torch tip facing to the right.

b)

Grasp gas cup firmly in

your right hand.

c)

Turn gas cup clockwise

only and pull cup out to the

right.

WARNING!

do not turn gas

cup anti-clockwise, as this will

damage internal spring.

d)

Unscrew the copper

contact tip (right hand thread)

to remove.

4.5.1. Check welder is switched off “0” and that the earth clamp is away

from the torch tip. Connect the welder to the mains power supply

and set the voltage switches to MIN/1. See fig.8.

4.5.2. Set the wire speed knob to position 5 or 6. Turn on the mains

power switch on the front panel. Keeping the torch cable as straight

as possible press the torch switch. The wire will feed through to

the torch.

4.5.3. When wire has fed through, switch welder off, unplug from mains.

a) Take torch in left hand, slide contact tip over the wire and screw

it back into place.

b) Grasp gas cup in right hand, push onto torch head and turn clockwise

only.

WARNING!

do not turn gas cup anti-clockwise, as this will damage

internal spring.

c) Cut wire so that it is just protruding from the cup.

4.6. Setting wire tension.

IMPORTANT:

You must set the correct tension, too little or too

much tension will cause problematic wire feed and result in a poor

weld.

4.6.1. For mild steel 0.6mm wire the wire tension screw must be fully

tightened and undone approximately two complete turns (fig.6).

4.6.2. Correct tension between the rollers is checked by slowing down the

wire between the fingers. If the pressure roller skids the tension is

correct. Try to use the lowest tension possible as too high a tension

will deform the wire and may result in blowing a fuse on the printed

circuit board. When you have completed welding disconnect the

unit from the mains supply and store it in a safe, dry place.

Note

: Damaged torches and cables are not covered under warranty.

fig.6

fig.7

5. WELDING PRINCIPLES

© Jack Sealey Limited

SUPERMIG140 Issue No:2(L) 05/08/14