4. INSTRUCTIONS FOR USE

WARNING! Before using the helmet for welding ensure you

have read and understood the safety instructions in Section 1.

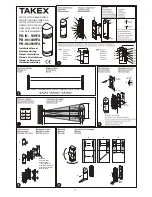

4.1

Assemble the headband parts (see fig.1) into the mask as

indicated in fig.2. Before the mask can be used the

headband must be adjusted to fit the user properly.

4.2

ADJUSTING THE FIT OF THE HELMET.

The overall circumference of the headband can be made

larger or smaller by pushing in and rotating the knob on the

back of the headband (See adjustment ‘A’ in fig.2). This

can be done whilst wearing the helmet and allows just the

right tension to be set to keep the helmet firmly on the

head without it being too tight.

4.3

If the headband is riding too high or too low on your head

adjust the strap which passes over the top of your head. To

do this release the end of the band by pushing the locking

pip out of the hole in the band. Slide the two portions of the

band to a greater or lesser width as required and push the

locking pip through the nearest hole (See adjustment ‘B’ in

fig.2).

4.4

Test the fit of the headband by lifting up and closing down

the helmet a few times whilst wearing it. If the headband

moves whilst tilting re-adjust it until it is stable.

4.5

ADJUSTING HELMET TILT

.

If the cartridge window is not aligned with the eyes when

the helmet is in the lowered position adjust the tilt of the

helmet in relation to the headband. Referring to fig.2 loosen

the knob ‘C’ adjacent to the tilt plate ‘D’. Lift the tilt plate off

the fixed peg within the helmet and rotate it to the required

position and allow one of the holes in the plate to drop back

over the peg. Retighten the clamp knob ‘C’.

4.6 SELECTING SHADE LEVEL

4.6.1 Refer to the shade guide in Section 7 and adjust the knob

on the side of the helmet to the correct setting (fig.3).

4.7

GRIND POSITION.

Turn the shade knob (fig.3)

anti-clockwise until it clicks into the grind position.

When

grinding is finished the knob must be turned back to the

appropriate shade position before welding again.

Failure to

do this could result in damage to your eyes.

4.8 SELECTING DELAY TIME/RESPONSE TIME

4.8.1 The delay time in which it takes the lens to change from

dark to light or vice versa can be varied from 0.1sec to 0.9

sec, this adjustment is carried out by turning the delay time

knob on the inside of the cartridge, see fig.4.

4.9 SENSITIVITY

4.9.1 For normal ambient light conditions set the sensitivity knob

to the high setting (fig.4).

4.9.2 For conditions where there is an excess of light, which may

affect the performance of the lens, turn the knob to the low

setting.

fig.3

fig.4

3. SPECIFICATION

Original Language Version

PWH399 Issue No.1 03/06/10

fig.1

fig.2

Model No: ......................................................... PWH399

Shade Active: .................................................... 9 - 13 Variable

Shade Inactive:.................................................. 4

Viewing Area: .................................................... 96 x 42mm

UV/IR Protection:............................................... YES

Operating time, Light/Dark: ............................... 0.0001ms

Temperature Range:.......................................... -5°C to +55°C

Power: ............................................................... Solar Cells