8. troUBleshootiNG

4 pc Air AccessorY Kit

SUPPLIED WITH MODEL NO:

sAc5020epK.v2

9. sprAY GUN sAFetY

WArNiNG!

disconnect the spray gun from the air supply before changing accessories, servicing or performing any maintenance.

9

Familiarise yourself with this products application and limitations, as well as the specific potential hazards peculiar to the spray gun.

Paint cup remains pressurised after gun is disconnected from air line.

8

do Not

pull the trigger, but release the pressure by gently opening cup.

9

maintain the spray gun in good condition (use an authorised service agent).

9

Replace or repair damaged parts. Use recommended parts only. Non authorised parts may be dangerous and will invalidate the

warranty.

9

locate the spray gun in an adequate working area for its function, keep area clean and tidy and free from unrelated materials, and

ensure there is adequate ventilation and lighting.

9

Keep the spray gun clean for best and safest performance.

9

Wear approved respiratory protection and safety eye goggles.

9

Remove ill fitting clothing. Remove ties, watches, rings, and other loose jewellery, and tie back long hair.

9

Keep children and unauthorised persons away from the working area.

9

Avoid unintentional operation.

8

do Not

point spray gun at yourself, at other persons or animals.

8

do Not

carry the by the air hose, or pull the hose from the air supply.

8

do Not

use the spray gun for any purpose other than for which it is designed.

8

do Not

allow untrained persons to operate the spray gun.

8

do Not

get the spray gun wet or use in damp or wet locations or areas where there is condensation.

8

do Not

operate gun if any parts are missing or damaged as this may cause failure or personal injury.

8

do Not

direct air from the air hose at yourself or others.

9

When not in use switch the spray gun off, and disconnect from the air supply.

10. tYre iNFlAtor sAFetY

9

disconnect the gauge from the air supply before changing accessories, servicing or performing any maintenance.

9

maintain the

gauge in good condition (use an authorised service agent), and keep the gauge clean for best and safest performance.

9

Replace or repair damaged parts.

Use recommended parts only. Unauthorised parts may be dangerous and will invalidate

the warranty.

9

locate gauge in a suitable work area, keep area clean and tidy and free from unrelated materials and ensure there is adequate lighting.

9

Keep children and unauthorised persons away from the work area.

8

do Not

direct gauge outlet at yourself or at other persons or animals.

8

do Not

carry by the hose, or yank the hose from the air supply.

8

do Not

use the gauge for a task which it is not designed to perform.

8

do Not

operate the gauge when you are tired or under the influence of alcohol, drugs or intoxicating medication.

8

do Not

operate gauge if parts are missing or the gauge is damaged, as this may cause failure and/or personal injury.

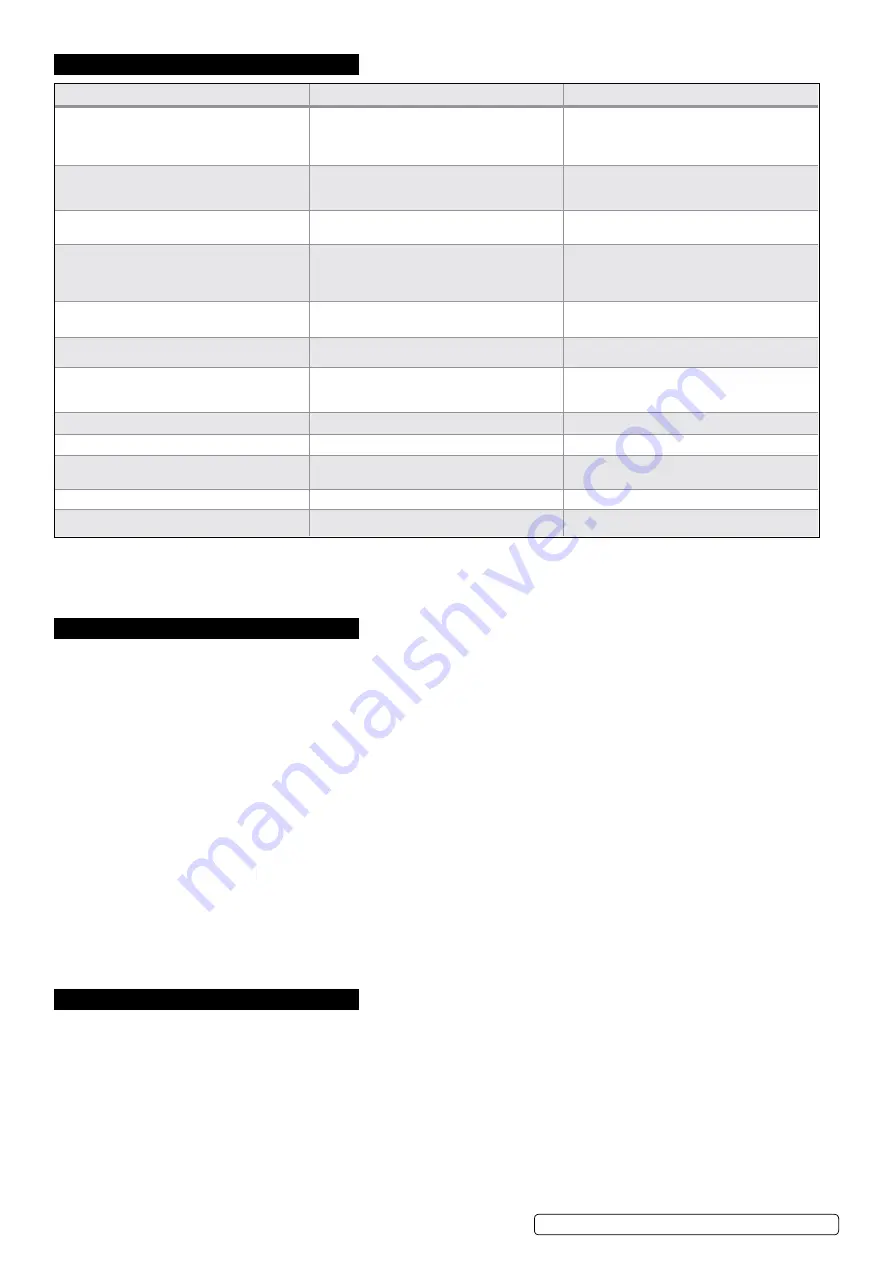

FAUlt

cAUse

remedY

1A) Pressure drop in the tank

Air leaks at connections

Run compressor to max. pressure, switch off

Brush soap solution over connections and look for

bubbles. Tighten connections showing leaks

If problem persists contact Authorised Service Agent

1B) Pressure drop in the tank

Air leaks from safety valve

operate the safety valve manually by pulling on the

ring. If valve continues to leak when in the closed

position it should be replaced

1C) Pressure drop in the tank

Air leaks from cylinder head gasket

Check tightness of head bolts. If leak continues

contact Authorised Service Agent

2) Pressure switch valve leaks when

compressor is idle

non-return valve seal defective

Empty the air tank. Referring to fig.6, remove the

non-return valve cap (3), spring (2) and seal (1)

Clean the seal and its seat, or if necessary replace

the seal

3) Air leaks from tank body or tank welds

Internal corrosion caused by infrequent tank

draining or non permitted modifications to tank

Tank could rupture or explode. Cannot be repaired

discoNtiNUe Use immediAtelY

4A) motor stops and will not restart

Thermal cut out has operated

Allow unit to cool for 30 minutes, then press reset

see fig.7.

4B) Motor stops and will not restart

Supply fuse has tripped

Reset fuse and restart unit. If repeated tripping

occurs replace the check valve or contact

authorised service agent

5) Compressor stops and does not restart

motor failure

Contact Authorised Service Agent

6A) Compressor does not stop at max. pressure

Pressure switch fault

Contact Authorised Service Agent

6B) Compressor does not stop at max. pressure

Filter clogged

Head gasket or valve fault

Replace filter element.

Contact Authorised Service Agent

7) Compressor noisy with metallic knock

Bearing or piston damage

Contact Authorised Service Agent

8) Excessive moisture in discharged air

High humidity environment

drain tank after each use

Original Language Version

© Jack Sealey limited

S

AC5020E.V3, SAC5020EPK.V2 Issue 1 13/06/19