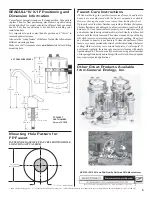

Inlet Line

Outlet Line

Figure

6

Figure

7

Cartridge Replacement Instructions

7. Mount Faucet.

Slide open side of Faucet

Mounting Nut onto reduced diameter,

un-threaded section of Faucet Stem now

beneath the sink, and slide the Nut

upwards to contact the threads. Then

carefully engage the threads, being

careful to not cross thread. Hand tighten

as necessary to hold the Faucet in place,

but do not use tools and do not

overtighten.

Check alignment and

position of Faucet, and adjust as

necessary.

(We suggest you practice

threading the Nut to the Stem above the

sink, prior to the actual installation, to

become familiar with the method before

installing Faucet to sink.)

8. Connect Inlet and Outlet lines.

Connect

free end of Thermoplastic Connection

Hose from Faucet Stem to Outlet (center)

Port on the Pressure Vessel. Tighten

securely.

Do not overtighten.

Connect

remaining Hose from fitting on cold

water supply line to Inlet (outside) Port

on top of Pressure Vessel.

Do not

overtighten.

All Seagull

®

IV X-1 units employ a RS-1SG Cartridge. The rated average capacity for the RS-1SG

Cartridge is 1,000 gallons. Actual capacity will vary depending on operating conditions and the quality

of the water source. Cartridges should be replaced when the flow rate decreases or when foul tastes or

odors become apparent (evidence of extra heavy loading of sulfur, tannin, iron or contamination), or

annually otherwise. Installing a Cartridge is easily accomplished as follows:

A. Close cold water supply valve.

B. Open X-1F Faucet,

and keep it open

until new Cartridge is installed and

operating.

C. Remove unit from Mounting Bracket,

place over a large sauce pan or other

container, remove V-Clamp and drain

loose water from Pressure Vessel. (If

Pressure Vessel halves remain attached

due to “set,” pull apart manually or

momentarily allow a small amount of

water to flow into the unit with the X-

1F faucet closed to separate the halves.

If X-1F faucet is closed, be sure and

reopen before continuing with next

step).

D. Remove expended Cartridge

by

placing plastic bag over it and turning

counter clockwise. Close bag and

discard. Rinse inside of Pressure Vessel

9. Mount unit on Bracket

by placing the

V-Clamp over the raised section on top

of the Bracket. Open the X-1F Faucet to

allow air to exhaust slowly. Open Valve

on cold water service line. Check for

leaks. Allow water to run for several

minutes to clear line and system of air

and any loose materials. Please note that

for the first few days you may see

entrapped air bubbles within the water.

This is perfectly normal and will cease

after the unit has processed several

gallons of water. Also, some black

“fines” from inside of cartridge may flow

with the first few gallons of water. These

are harmless, if consumed, or may be

discarded.

Figure

8

3

Inlet Line

connects

to Cold Water

Supply.

Outlet Line

connects to

Pure Water

Faucet.

QUESTIONS?

Call 1-800-441-8166

for Customer service

with water and wipe clean with paper

towel Be sure thick White Rubber

Cartridge Seal is bonded in place inside

the top of the unit.

E. Align carefully,

and being careful not

to cross thread, thread new Cartridge

into place

UNTIL CONTACT IS

FIRST MADE WITH SEAL, THEN

TIGHTEN ONE QUARTER TURN

ONLY. DO NOT OVERTIGHTEN.

Please refer to

Step 2 and Figure 2.

Reassemble the two stainless steel

halves together, making sure the

rubber Housing Gasket is in

place between the two halves.

IMPORTANT:

Make sure Gasket is

not cut or nicked, and be sure

housing has not been dropped or dented

on either of the two mating halves.

F.

Refer to Step 9 to place unit back in

service.

H

ELPFUL

H

INTS

If you have difficulty separating the upper and

lower halves of the pressure vessel, water

pressure can help. Turn off cold water supply;

remove the V-clamp and close the pure water

faucet. With a pan ready to catch water from

the unit, slowly turn on the water supply. Once

the unit begins to separate, turn off the water

supply and proceed according to your

Installation and Operations instructions.

You may apply a light coating of petroleum

jelly to the housing gasket to assure ease of

opening and closing of the system.

When a new cartridge is put into service, you

may see air bubbles and black particles in the

water until the system has stabilized. These are

harmless and will be purged from the system

within the first few liters or quarts of water.