11

Italiano

ENGLISH

International registered trademark n. 804888

PART FOR BOTH INSTALLER AND END-USER

PERIODIC MAINTENANCE

ALL

OPERATIONS

MUST

BE

CARRIED

OUT

EXCLUSIVELY

BY

AN

AUTHORIZED

INSTALLER

GATE WARNINGS AND PRECAUTIONS

ALL

OPERATIONS

MUST

BE

CARRIED

OUT

IN

ABSENCE

OF

POWER

SUPPLY

Check the robustness and the stability of the gate; check the leaning and rotation points of the gate (hinges)

Check the oil level and refill, in case of low level, with the oil recommended by the producer

Check the function of the release

Check the function of the by-pass valves

Check and grease the fixation pins

Check the integrity of the connecting cables

Check the good status of all parts which are subject to efforts (back fixation, oscillating fork,and front fixation)

If some parts are corroded, replace them

Check the functionality of all the accessories especially the function of all safety devices and of the Encoder

Annual

Annual

Annual

Annual

Annual

Annual

Annual

Annual

Annual

A

FTER

THE

MAINTENANCE

IT

IS

NECCESSARY

TO

REPEAT

ALL

TESTS

BEFORE

RESTARTING

AUTOMATION

T

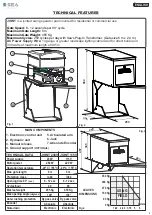

min

-30°C

T

max

+60°C

STORAGE TEMPERATURE

Humidity

min

5% without condensation

Humidity

max

90% without condensation

RISK EXAMINATION:

The points pointed by arrows are potentially dangerous. The installer must take a thorough risk

examination to prevent crushing, conveying, cutting, grappling, trapping so as to guarantee a safe installation for people,

things and animals (

). As for misunderstandings that

Re. Laws in force in the Country where installation has been made

may arise refer to your area distributor or call our help desk. These instructions are part of the device and must be kept in a

well known place. The installer shall follow the provided instructions thoroughly.

products must only be used to

SEA

automate doors, gates and wings. Any initiative taken without

explicit

SEA

authorization will preserve the manufacturer from whatsoever responsibility. The

installer shall provide warning notices on not assessable further risks.

in its

SEA

relentless aim to improve the products, is allowed to make whatsoever adjustment

without giving notice. This doesn’t oblige

to upgrade the past production.

SEA

SEA

can not be deemed responsible for any damage or accident caused by product

breaking, being damages or accidents due to a failure to comply with the instructions

herein. The guarantee will be void and the manufacturer responsibility will be nullified

if

original spare parts are not being used.

SEA

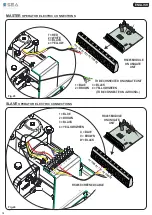

The electrical installation shall be

carried out by a professional technician who will release documentation as requested

by the laws in force.

Packaging materials such as plastic bags, foam polystyrene,

nails etc must be kept out of children’s reach as dangers may arise.

INITIAL TEST AND STARTING OF THE AUTOMATION:

After having completed the necessary operations for a correct

installation of the product and after having evaluated all the risks which could arise in any installation,

it is necessary to

test the automation to guarantee the maximum security and, in particular, to guarantee that the laws in force are

fully respected

. The first Start must be executed according to the rule

EN 12445

which establishes the methods of tests

for checking the gate automation respecting the limits established by the rule

EN 12453.

SAFETY PRECAUTIONS:

All electrical work should comply with the current regulations. A 16A / 0,030 differential switch

must be used. Separate the source cables (operators, power supply) and command cables (photocells, push-buttons,

etc). Be sure the entire system is properly earth bonded. Always run cables in separate ducts to prevent interferences.

INTENDED USE:

The operator has been designed to be used for the automation of swing gates only.

SPARE PARTS:

Send request for spare parts to:

SEA S.p.A. - Teramo - ITALY -

www.seateam.com

SAFETY AND ENVIRONMENTAL COMPATIBILITY:

Don’t waste product packing materials and/or circuits.

STORAGE:

must be properly packaged, handled with care

;

Materials

and with appropriate vehicles

WARRANTY LIMITS

-

see the sales conditions

MAINTENANCE AND DECOMMISION:

must only be carried out by specialised and authorised personnel.

THE MANUFACTURER CAN NOT BE DEEMED RESPONSIBLE FOR ANY DAMAGE OR INJURY CAUSED BY

IMPROPER USE OF THIS PRODUCT

;

SEA S.p.A. reserves the right to make any required modification or change to the products and/or to this manual without

any advanced notice obligation.