9711-44 Ku-Band TXRX

Installation (144” Radome)

3-35

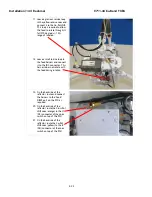

If your modem cannot use the Modem Console Port connection you will have to

provide a transmit inhibit output from the ACU by connecting a SW2 wire connection

to the modem to comply with FCC Order 04-286 and WRC-03 Resolution 902

.

•

Dual or Quad Antenna Arbitrator coax switches in dual antenna configurations. The coax

switches select which antenna is feeding signal to the below decks equipment.

•

Mute the Transmit output of the Satellite Modem used in TX/RX antenna configurations

when the antenna is positioned where people may be harmed by the transmit power

emanating from the antenna (RF Radiation Hazard).

•

Mute the Transmit output of the Satellite Modem used in TX/RX antenna configurations

when the antenna is mispointed by 0.5 degrees, or more, and keep it muted until the

antenna has been within 0.2 degrees of peak pointing to the satellite for a minimum of 5

seconds (FCC part 25.221 & 25.222 TX Mute requirement).

3.10.7.5.

TS2 Synchro Gyro Compass Input.

Use the R1, R2, S1, S2 and S3 screw terminals to connect the Synchro Gyro Compass to the ACU.

3.10.7.6.

TS3 Step-By-Step (SBS) Gyrocompass Input.

Use the COM, A, B and C screw terminals to connect the SBS Gyrocompass to the ACU. Some SBS

Gyro distribution boxes have terminals which are labeled S1, S2 & S3 instead of A, B and C.

3.10.7.7.

TS4 Power

•

VREG

Screw terminal is used to provide a regulated DC operating voltage to ancillary

equipment. Voltage out is dependent upon which terminal mounting strip assembly is

provided. 126865-1 supplies 8Vdc @ 1Amp, while the 126865-2 assembly supplies 5Vdc

@ 2Amps.

•

GND

Screw terminal is the ground reference for the regulated and unregulated power

terminals.

•

12/24

Screw terminal is commonly used to provide operating voltage to an external GPS,

Dual Antenna Arbitrator or other below decks tone generators or switches. Voltage output

is based on the T.M.S assemblies JP5 jumper settings.

3.10.7.8.

TS5 NMEA A/B, GPS output.

•

RxA- and RxA+- screw terminals, which are defined as the NMEA A connection is used to

connect to the ships Gyro Compass (Heading). The NMEA0183 compliant inputs are then

connected via a 9 pin ribbon cable to the ACU’s J2 NMEA communications port. A GPS

(Latitude and Longitude) input may also be connected, but is not required because there is

a GPS device already installed in your antenna..

NOTE:

If you connect a ships GPS to the

terminal mounting strip, you

MUST

disconnect the GPS antenna on the antenna

pedestal.

•

RxB- and RxB+ screw terminals, which are defined as the NMEA B connection is used to

connect to the ships Gyro Compass (Heading). The NMEA0183 compliant inputs are then

connected via a 9 pin ribbon cable to the ACU’s J2 NMEA communications port. A GPS

(Latitude and Longitude) input may also be connected, but is not required because there is

a GPS device already installed in your antenna.

•

TxA- screw terminal is used to provide a Pseudo GPS (GGA and GLL formats) output to

other system components such as a Satellite Modem.

3.10.8.

Other BDE connections

Connect your other Below Decks Equipment (ie, telephone, fax machine and computer equipment) to

complete your configuration.

3.11.

Final Checks

3.11.1.

Visual/Electrical inspection

Do a visual inspection of your work to assure that everything is connected properly and all cables/wires are

secured.

Summary of Contents for 9711-44 KU-BAND TX/RX

Page 3: ......

Page 12: ...Table of Contents xii This Page Intentionally Left Blank ...

Page 24: ...Site Survey 9711 44 Ku Band TXRX 2 8 This Page Intentionally Left Blank ...

Page 64: ...Installation 144 Radome 9711 44 Ku Band TXRX 3 40 This Page Intentionally Left Blank ...

Page 112: ...Basic Setup of the ACU 9711 44 Ku Band TXRX 5 4 This Page Intentionally Left Blank ...

Page 114: ...Setup Ships Gyro Compass 9711 44 Ku Band TXRX 6 2 This Page Intentionally Left Blank ...

Page 116: ...Setup Band Select 9711 44 Ku Band TXRX 7 2 This Page Intentionally Left Blank ...

Page 122: ...Setup Home Flag Offset 9711 44 Ku Band TXRX 9 4 This Page Intentionally Left Blank ...

Page 130: ...Setup Searching 9711 44 Ku Band TXRX 11 6 This Page Intentionally Left Blank ...

Page 150: ...Antenna Specific Operation 9711 44 Ku Band TXRX 16 4 This Page Intentionally Left Blank ...

Page 154: ...Functional Testing 9711 44 Ku Band TXRX 17 4 This Page Intentionally Left Blank ...

Page 158: ...Installation Troubleshooting 9711 44 Ku Band TXRX 18 4 This Page Intentionally Left Blank ...

Page 180: ...Maintenance 9711 44 Ku Band TXRX 19 22 This Page Intentionally Left Blank ...

Page 198: ...Drawings 9711 44 Ku Band TXRX 23 2 This Page Intentionally Left Blank ...

Page 205: ......

Page 210: ......

Page 218: ......

Page 230: ......

Page 231: ......

Page 242: ......

Page 243: ......

Page 252: ......

Page 254: ......

Page 256: ......