START UP

Pre-Start Inspection

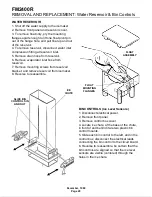

1. Remove the front, left, and right side

service panels.

2. Check that any styrofoam shipping blocks

have been removed.

3. Inspect the interior of the machine for loose

screws or wires. Check that no refrigerant

lines are rubbing each other. Check that the

fan blade turns freely (remote condenser).

4. Check that the refrigerant lines are properly

installed.

5. Check that the electrical power has been

on for at least 12 hours and that the

compressor domes are warm.

6. Check that the unit is installed corerectly

according to the final check list on page 14.

Start Up

1. Go through the pre-start inspection.

2. Open the hand valve, observe that water

enters the water reservoirs, fills the tubes from

the reservoirs to the evaporators, and then

shuts off. Check for leaks.

3. Open each King (receiver service) valve.

4. Switch each master switch on.

The electrical start up sequence is now on

automatic.

A. There should be a short (15 second) delay

before the gearmotor starts.

B. After the gearmotor starts, the liquid line

valve will open, the low pressure control will

close and the compressor will start.

5. The remote condenser fan turns, and the

condenser begins to discharge warm air.

6. The unit should soon be making ice, if

desired the low side pressure of each system

can be checked, it should be 30 psig + or - 4

psig. The discharge pressure will depend

upon air and water temperatures, but should

be between 200 psig and 280 psig.

7. THERE ARE NO ADJUSTMENTS TO

MAKE, so replace the panels.

8. Clean and/or sanitize the storage bin

interior, wipe off the exterior with a clean,

damp cloth.

9 Give the owner/user the service manual,

instruct him/her in the operation of the unit,

and make sure they know who to call for

service.

10. Fill out the manufacturers registration

card, and mail it to the Scotsman Factory.

11. Fill out the field quality audit form, and mail

it to the Scotsman factory.

FM2400R

December, 1988

Page 13