Assembly

20

05.00|21151452 KSP plus-IN, KSP-LH plus-IN, KSP plus-IN2, KSP-LH plus-IN2 |en

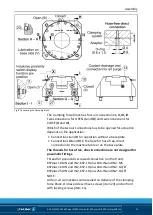

Image 2 assembling the clamping block

Assembly with clamping sleeves

Mount the clamping block on the machine table together with

clamping sleeves (item 27) and screws (item 19).

Assembly with fitting screws:

There are two fittings in the housing (item 1) that, along with the

optional fitting screws (item 9), are used to center the clamping

block on the machine table with repeat accuracy. Do not realign

the clamping block after removing it from the machine table (e.g.,

after replacing the seals). When using fitting screws (item 9), use

them instead of the clamping sleeves (item 27) and the two

corresponding screws (item 19).

Connecting the clamping block

Make sure the power supply is off when connecting the clamping

block. See chapter "Basic Safety Notes".

CAUTION

Risk of workpiece loss and damage to system due to loss of air

pressure caused by damaged pneumatic lines.

Always make sure the connections are tight, and use appropriate

protection covers to protect the pneumatic hoses and lines from

hot chips.

5.3