Installation

The Load Genie has 1/2 NPT “IN” and “OUT” ports and is suit-

able for compressor with discharge capacities of up to 32

SCFM . The Load Genie is typically installed onto the tank

with a short pipe nipple. The “OUT” port must be connected

directly to the tank with no other check valves in between

the tank and the Load Genie. (NOTE: On some retrofit appli-

cations, there may have been a type of check valve known

as an “In Tank” check valve previously installed. Make sure

there is a clear air path between the tanks and “OUT” port

before installing the Load Genie. The compressor discharge

line can now be routed into the “IN” port of the Load Genie.

The installation is now complete.

Regulator Adjustment

Cutout pressure is adjustable from 60 PSI to 175 PSI with

the standard silver spring. The differential (difference

between cut-out and cut-in pressures) is typically set at the

factory at approximatly 15% of the cut-out pressure. This is

usually a suitable differential and will not normally need to

be readjusted.

1. Loosen range screw jam nut first.

2. Turn range screw clockwise to raise cut-out and cut-in

pressure levels and counter clockwise to decrease cut-

out and cut-in levels.

3. Start compressor and note cut-out and cut-in presures.

Make adjustments as necessary using range

adjustment screw; when acceptable, tighten range

adjustment screw jam nut.

4. Adjust the cut-in pressure to the desired level per

steps #1, #2, and #3, as shown above.

5. Loosen differential screw jam nut and turn differential

screw clockwise to raise cut-out pressure and

counter clockwise to decrease the the cut-out

pressure.Tighten differential screw jam nut when

desired cut-out pressure is set. Since step #5 should

not change the desired cut-in pressure set in step #4,

adjustment is now complete.

Use with Gasoline Engine

Throttle Controls

A 1/8 NPT tapped port in the end of the Load Genie allows

the use of a throttle control to slow down the driving engine

when in the cutout (venting) mode. The throttle control is

simply a small (e.g., 1/2” dia. X 1” stroke) single-acting, spring

return air cylinder which moves the throttle lever on the

engine to the idle position when the cylinder is pressurized

while in the cut-out mode. 709 Throttle control is specifi-

cally designed for this application.

It is improtant that the

throttle control air cylinder is leak-tight and that all con-

nections between that Load Genie and the air cylinder are

leak-tight.

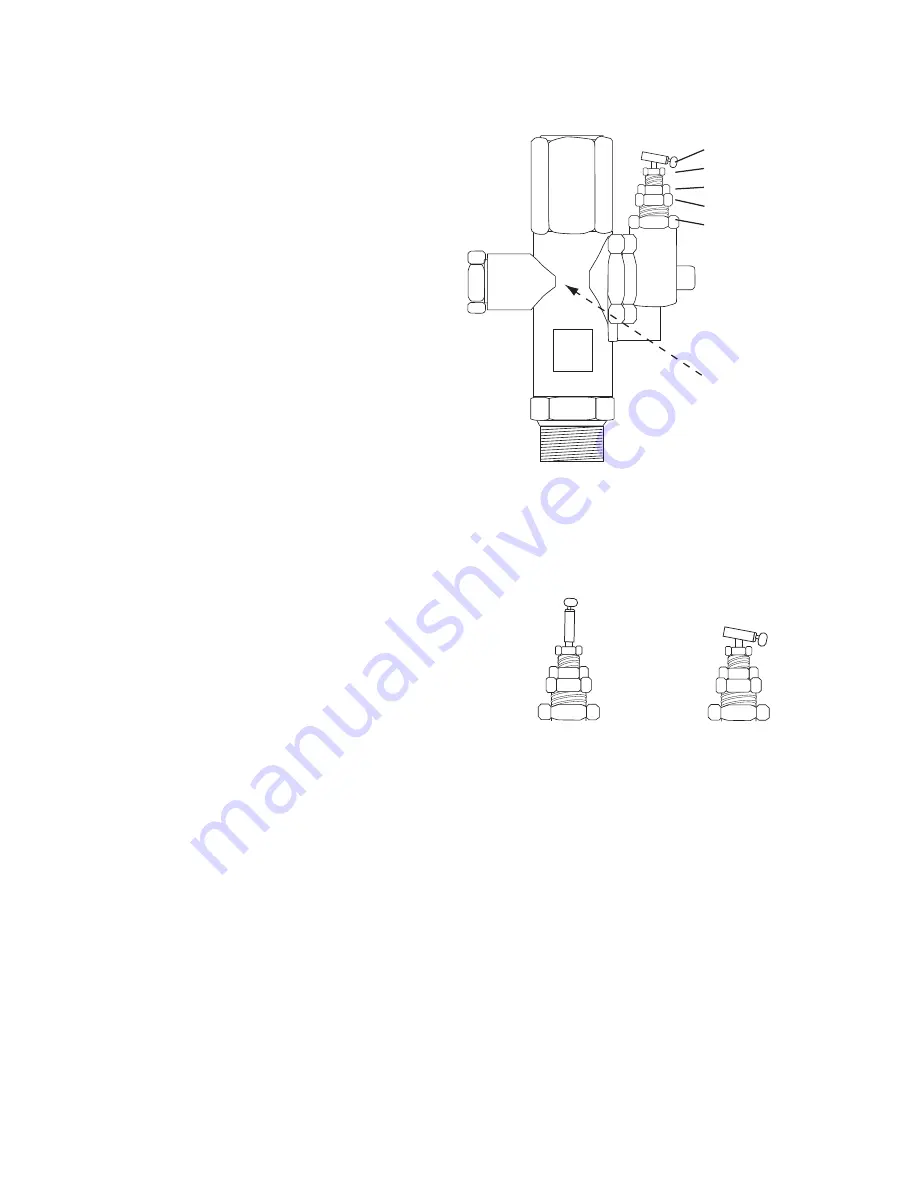

Load Genie Instructions

9

VENT

Inlet (Connected to Compressor)

1/8 NPT

Throttle Control Port

Differential Jam Nut

Differential Adjustment Screw

Range Jam Nut

Range Adjustment Screw

Out (Connected to Tank)

Vent Port

(See rear, open to

Atmosphere)

Loadgenie3 112807.ai

Easy Start Lever

Start Position

Run Position

Starting Unit

Easy Start: Place Easy Start Lever in upright position. Start unit.

When running smoothly, flip lever to run position.