13

SLC440COM Series

SLG440COM Series

Operating instructions

Safety light curtain / safety light grid

EN

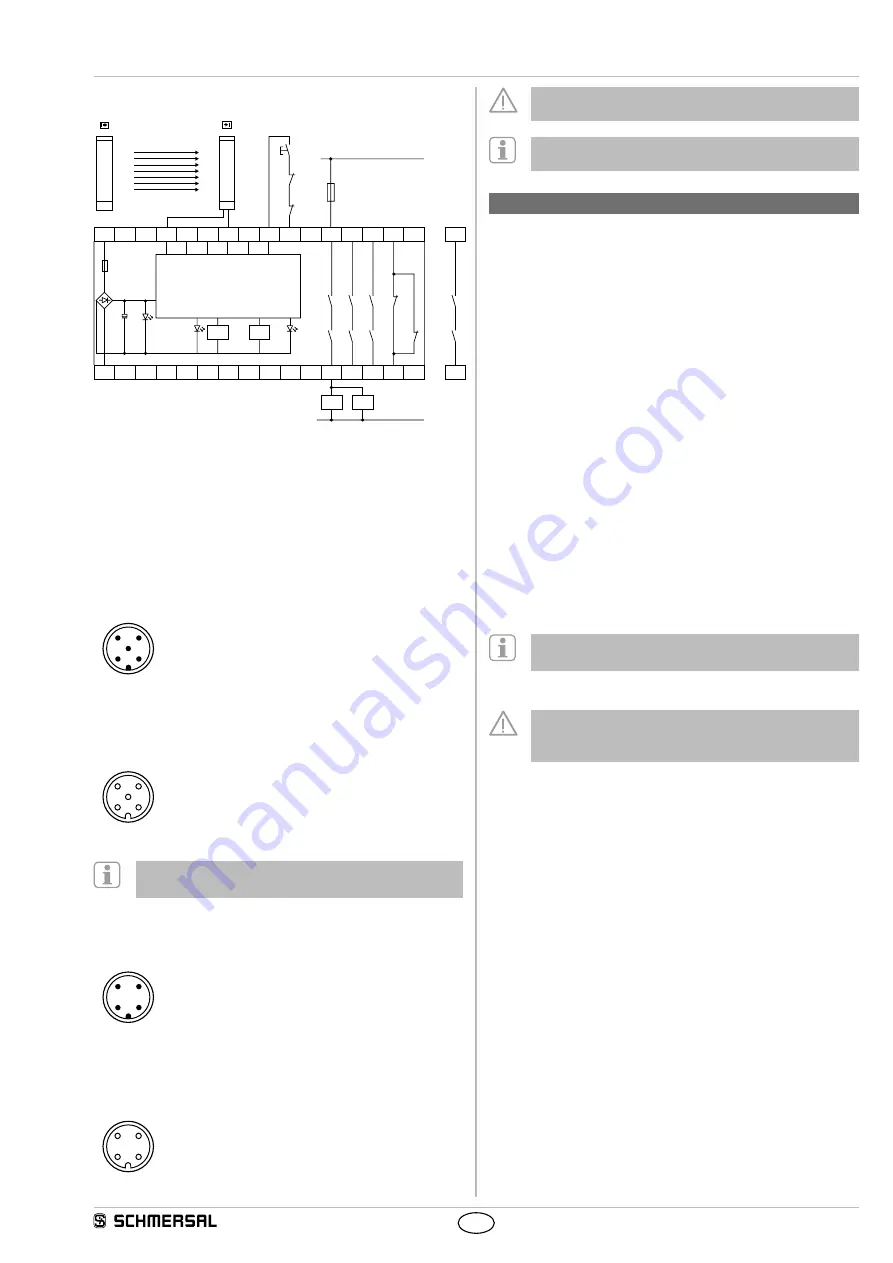

5.2 Wiring example with safety relay module

A2

A1

S12 S11 S21 S22

X1 X2

13

L1

33 41

23

K2

K1

Ui

K2

K1

F1

Ansteuerlogik/

Logic

14 24 34 42

N

S

J

K

A

K

B

K

A

K

B

K

B

K

A

Safety relay module

• Contactor control K

a

and K

b

at X1/X2

• Command device

J

Restart interlock restart at X1/X2

• OSSD outputs at S12 and S22

• QS-switch = nQS, deactivate cross-wire short detection

5.3 Connector configuration Receiver, Emitter & Cable

RECEIVER

SLC Connector

M12, 5-pole

Designation

Description

3

2

5

1

4

1 BN 24 VDC

power supply

2 WH OSSD 1

Safety output 1

3 BU 0 VDC

power supply

4 BK OSSD 2

Safety output 2

5 GY Release/restart

interlock

Acknowledgement restart

interlock

Cable: Connector

female

M12, 5-pole

3

2

5

1

4

It is possible to use the Automatic operating mode with a

4-pole cable (without pin 5 restart interlock)

EMITTER

SLC Connector

M12, 4-pole

Designation

Description

3

2

1

4

1 BN 24 VDC

power supply

2 WH Not used

Do not connect a signal

(do not wire)

3 BU 0 VDC

power supply

4 BK Not used

Do not connect a signal

(do not wire)

Cable: Connector

female

M12, 4-pole

3

2

1

4

The colour codes are only valid for the cable types mentioned

below "optional accessories"

For UL evaluated products we do recommend to use the UL

style cable 20549

6. Set-up and maintenance

6.1 Check before start-up

Prior to start-up, the following items must be checked by the

responsible person

Wiring check prior to start-up

1 The voltage supply is a 24V direct current power supply (see

technical specifications), which meets the CE Directives, Low Voltage

Directives A power downtime of 20 ms must be bridged

2 Presence of a voltage supply with correct polarity at the AOPD

3 The connecting cable of the emitter is correctly connected to

the emitter and the connecting cable of the receiver is correctly

connected to the receiver

4 The double insulation between the light curtain output and an

external potential is guaranteed

5. The outputs OSSD1 and OSSD2 are not connected to +24 VDC.

6 The connected switching elements (load) are not connected to

+24 VDC.

7 If two or more AOPD are used within close range compared to each

other, an alternating arrangement must be observed Any mutual

interference of the systems must be prevented

Switch on the AOPD and check the operation in the following way:

The component performs a system test during approx 2 seconds after

the operating voltage has been switched on After that, the outputs are

enabled if the protection field is not interrupted The status indication at

the receiver is on

In case of incorrect functionality, please follow the instructions

listed in the chapter Fault diagnostic

6.2 Maintenance

Do not use the AOPD before the next inspection is

terminated An incorrect inspection can lead to serious and

mortal injuries

Conditions

For safety reasons, all inspection results must be archived The

operating principle of the AOPD and the machine must be known in

order to be able conducting an inspection If the fitter, the planning

technician and the operator are different persons, please make sure

that the user has the necessary information at his disposal to be able

conduct the maintenance

6.3 Regular check

A regular visual inspection and functional test, including the following

steps, is to be performed:

1 The component does not have any visible damages

2 The optics cover is not scratched or soiled

3 Hazardous machinery parts can only be accessed by passing

through the protection field of the AOPD

4 The staff remains within the detection area, when works are

conducted on hazardous machinery parts

5 The safety distance of the application exceeds the mathematically

calculated one