3

AZ 415-../..

Operating instructions

Safety switch

EN

3. Mounting

3.1 General mounting instructions

The mounting holes are accessible after removal of the cover

The enclosure must not be used as an end stop Any mounting position

The mounting position however must be chosen so that the ingress of

dirt and soiling in the used opening is avoided

Mounting of the actuators:

See mounting instructions actuators

Please observe the remarks of the standards ISO 12100,

EN 953 and ISO 14119

The safety component and the actuator must be

permanently fitted to the safety guards and protected

against displacement by suitable measures (tamperproof

screws, gluing, drilling, pinning)

3.2 Dimensions

All measurements in mm

28

¤ 6,5

7,8

8

22,3

20

M20x1,5

8,8

A

88

84,6

46,5

103,6

26,8

29,5

¤ 11

Key

A Setting screw ball latch: 80-400 N

3.3 Adjustment

In the unlocked condition, the safety guard is kept in a closed condition

by the adjustable ball latch By rotating a hexagonal key wrench

clockwise, the desired holding force can be increased; if the hexagonal

key wrench is rotated counterclockwise, the holding force is decreased

The holding force must always be set as low as possible

4. Rear side Electrical connection

4.1 General information for electrical connection

The electrical connection may only be carried out by

authorised personnel in a de-energised condition

The contact labelling can be found in the wiring compartment of the

switch For the cable entry, suitable cable glands with an appropriate

degree of protection must be used Non-used input openings must be

sealed by means of threaded plugs After wiring, dust and soiling must

be removed from the wiring compartment

The conductors of the connecting cables must not obstruct the

movement of the switching lever.

Maximum tightening torque for the screws:

Cover 0.6 + 0.1 Nm; bottom cover 0.7 + 0.1 Nm

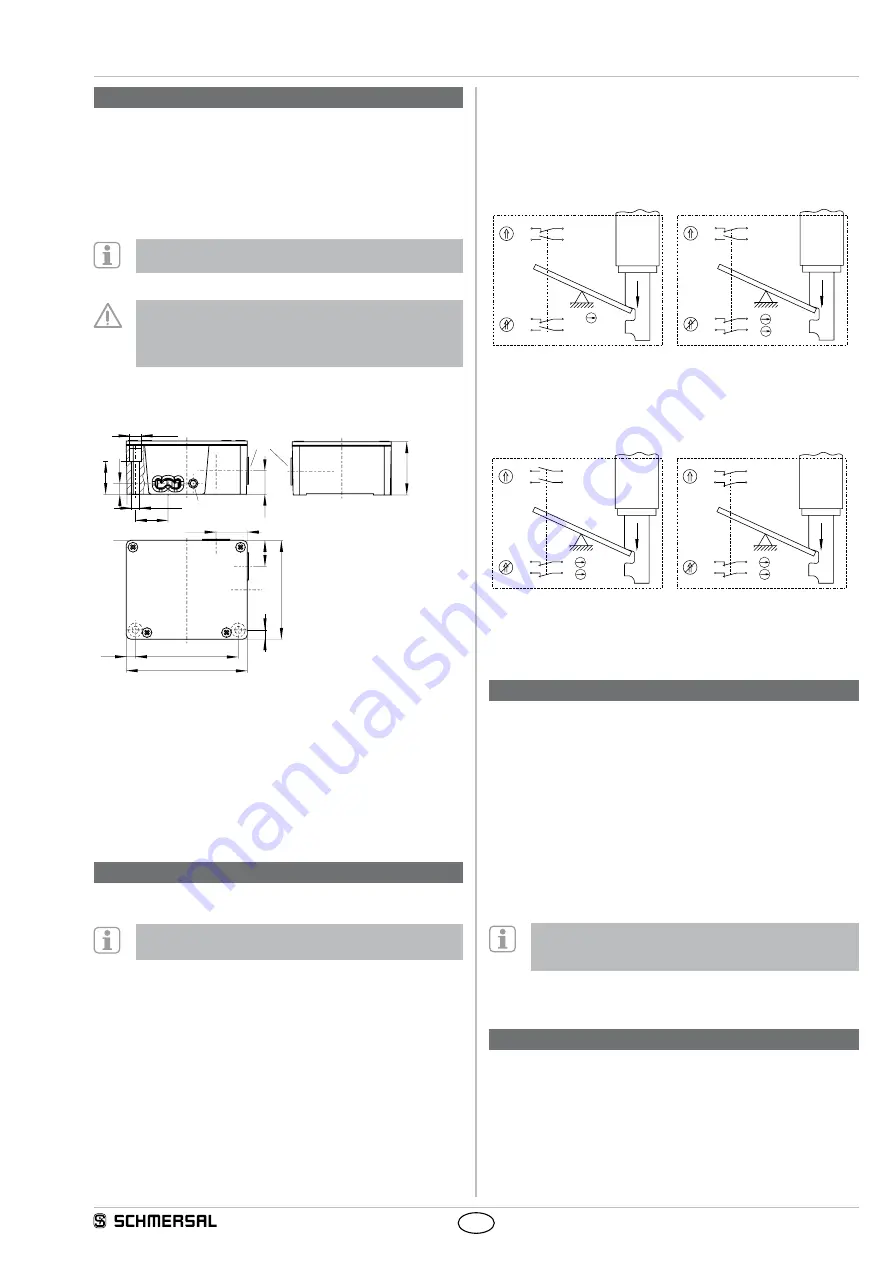

4.2 Contact variants

Contacts are shown with safety guard closed

AZ 415-11/11ZPK-M20

AZ 415-02/11ZPK-M20

S1

1 NO / 1 NC

S2

1 NO / 1 NC

S1

2 NC

S2

1 NO / 1 NC

21

13

21

13

22

14

22

14

S2

S1

21

13

11

21

22

14

12

22

S2

S1

AZ 415-02/20ZPK-M20

AZ 415-02/02ZPK-M20

S1

2 NC

S2

2 NO

S1

2 NC

S2

2 NC

13

23

11

21

14

24

12

22

S2

S1

11

21

11

21

12

22

12

22

S2

S1

Key

A

Positive break

P

Actuated

Q

not actuated

5. Set-up and maintenance

5.1 Functional testing

The safety function of the safety components must be tested

The following conditions must be previously checked and met:

1 Fitting of the safety switch and the actuator

2 Check the integrity of the cable entry and connections

3 Check the switch enclosure for damage

5.2 Maintenance

A regular visual inspection and functional test, including the following

steps, is recommended:

1 Check for correct installation of the actuator and the safety switch

2 Remove particles of dust and soiling

3 Check cable entry and connections

Adequate measures must be taken to ensure protection

against tampering either to prevent tampering of the safety

guard, for instance by means of replacement actuators

Damaged or defective components must be replaced.

6. Disassembly and disposal

6.1 Disassembly

The safety switchgear must be disassembled in a de-energised

condition only

6.2 Disposal

The safety switchgear must be disposed of in an appropriate manner in

accordance with the national prescriptions and legislations